Wood floor processing technology

A processing technology and wood flooring technology, which is applied in the direction of wood processing equipment, manufacturing tools, combined devices, etc., can solve the problem of troublesome slot milling processing efficiency, etc., and achieve the effect of easy and convenient milling slot processing operation of wooden floor and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

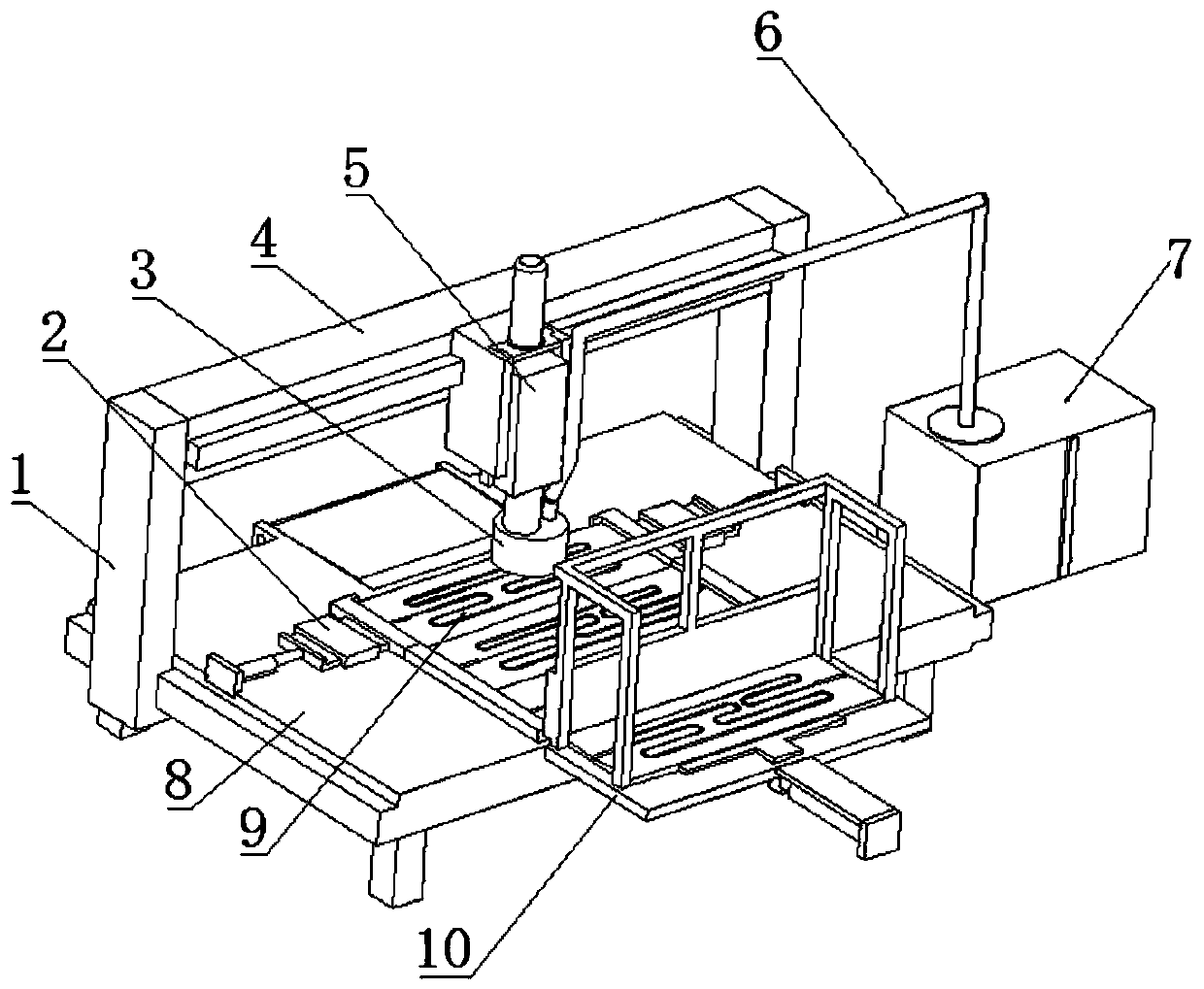

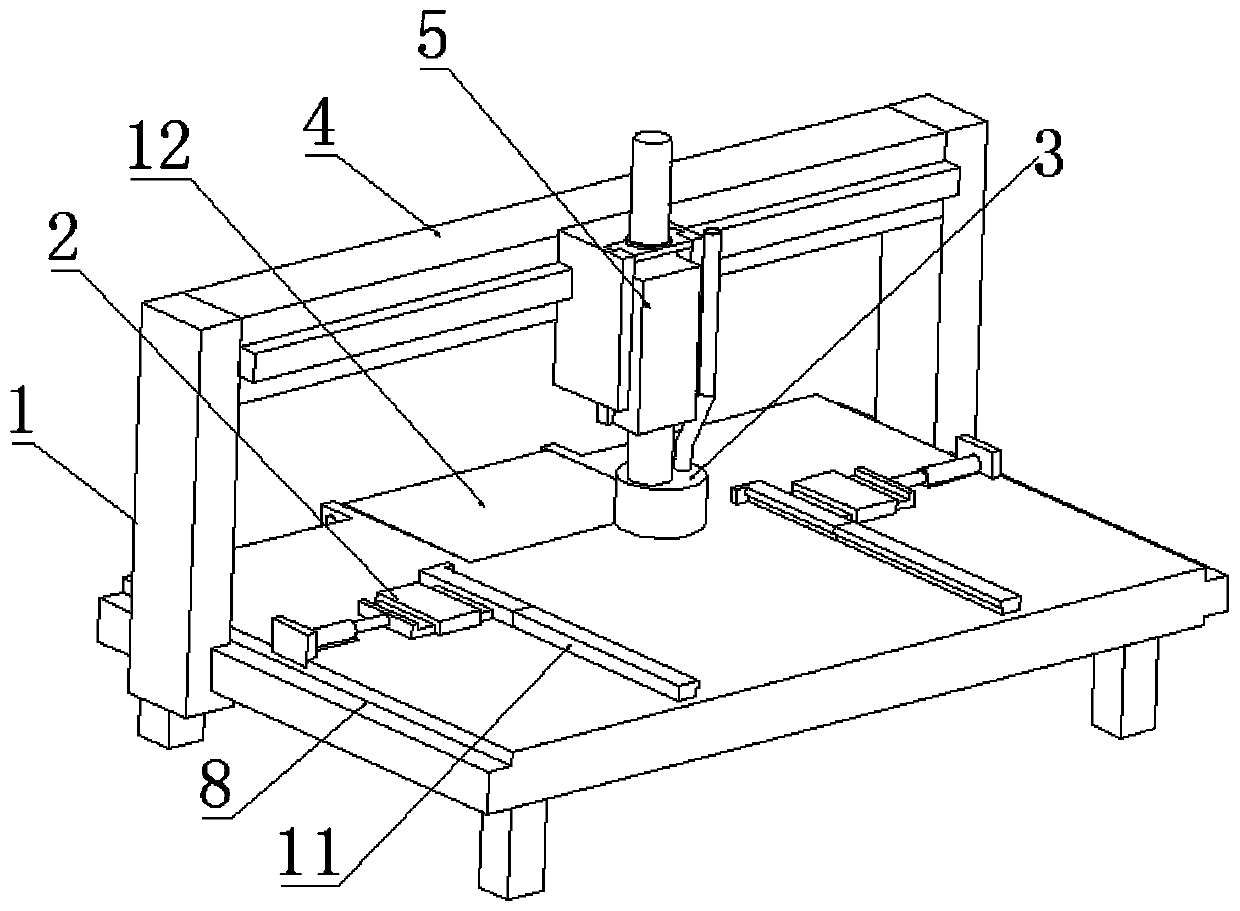

Examples

Embodiment 1

[0035] Embodiment 1, a kind of wooden floor processing technology, comprises the following steps:

[0036] S1: Plate treatment: place the purchased plates in the warehouse for aging treatment, and realize the natural drying treatment of the plates to achieve the effect of anti-corrosion and insect prevention;

[0037] S2: Plate thickness processing: use a planer to plan and process the surface of the plate to ensure the precise thickness of the plate;

[0038] S3: Plate cutting: cut the plate size with a cutting machine for the plate with processed thickness;

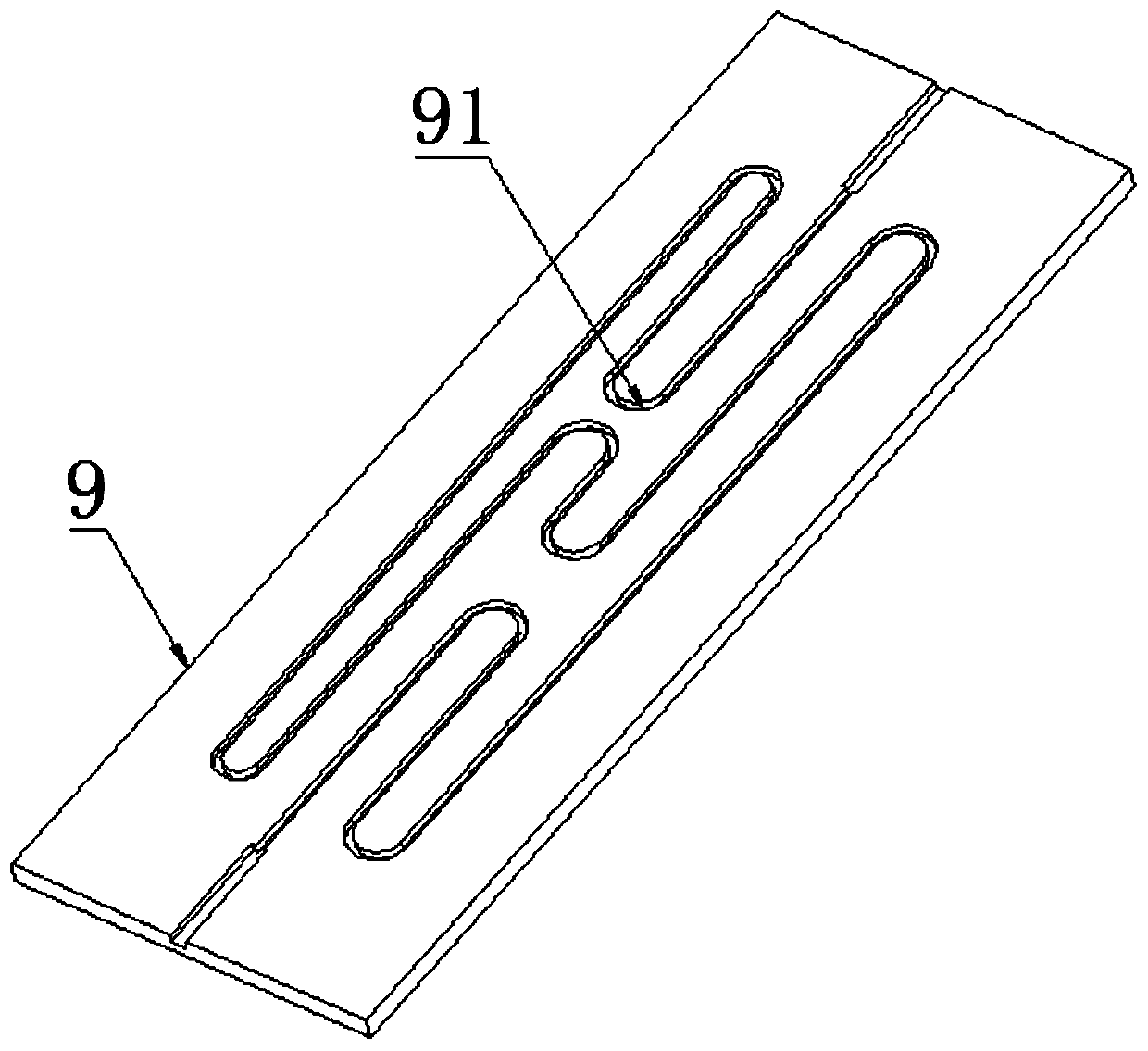

[0039] S4: surface sanding: use a sander to polish the surface of the wooden floor 9;

[0040] S5: Slot milling processing: engraving and processing the wiring groove 91 on the surface of the wooden floor 9 by an engraving machine;

[0041] S6: surface spraying: spraying the surface of the wooden floor 9 by spraying equipment;

[0042] S7: drying treatment: drying the painted wooden floor 3 by a drying device.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com