Inclined planer capable of easily discharging chips

An oblique, planer technology, applied in planer/slotting machine, planer, metal processing equipment, etc., can solve the problems of increased workload in production, unfavorable cleaning of bed debris, unnecessary cost increase, etc. Chips, force rationalization, effect of stroke length extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be described below in conjunction with the accompanying drawings and related examples. The implementation of the present invention is not limited to the following examples, and the present invention relates to relevant necessary components in the technical field, which should be regarded as The known technologies are known and mastered by those skilled in the art.

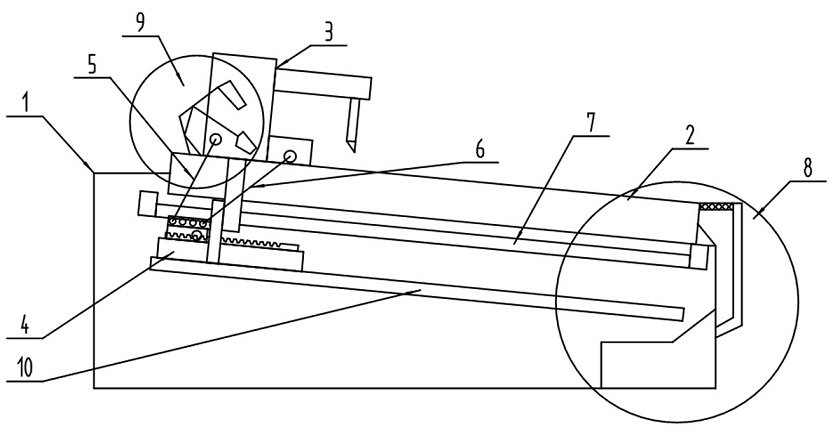

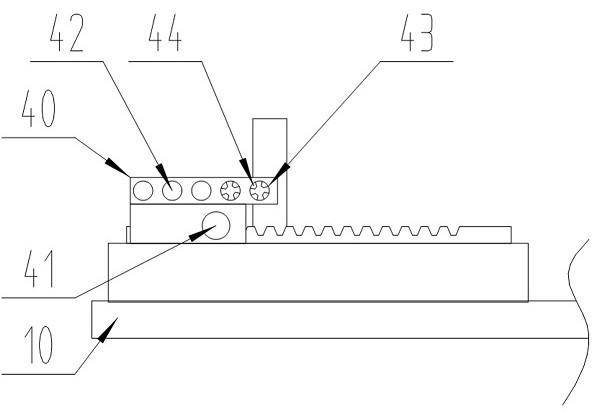

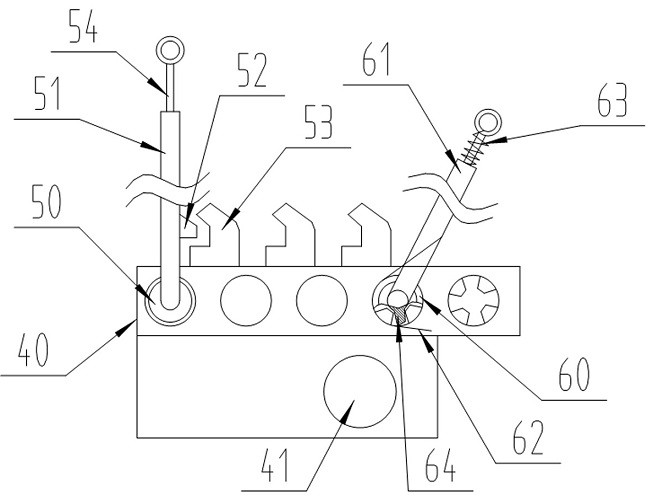

[0020] combine Figure 1 to Figure 5 As shown, an inclined type easy-to-remove chip planer includes a base 1 and a planer seat 3 connected to the planer. The base 1 is provided with a bed 2 that is not less than 15° and is inclined along the feeding direction of the planer. The bed 2 is movably connected with a planer seat 3 through the screw 7 arranged on both sides of itself, and the planer seat 3 is hinged with a balance traction table 4 through a pair of rigid connecting rods 5 and a pair of elastic connecting rods 6, and the The height of the elastic con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com