Planing machine capable of conveniently planing any plane of material

A plane and planing technology, which is applied in the field of machine tools, can solve the problems of inability to deal with processing waste and the inability of the planer to adjust the processing plane conveniently, and achieve the effects of easy collection, easy planing, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

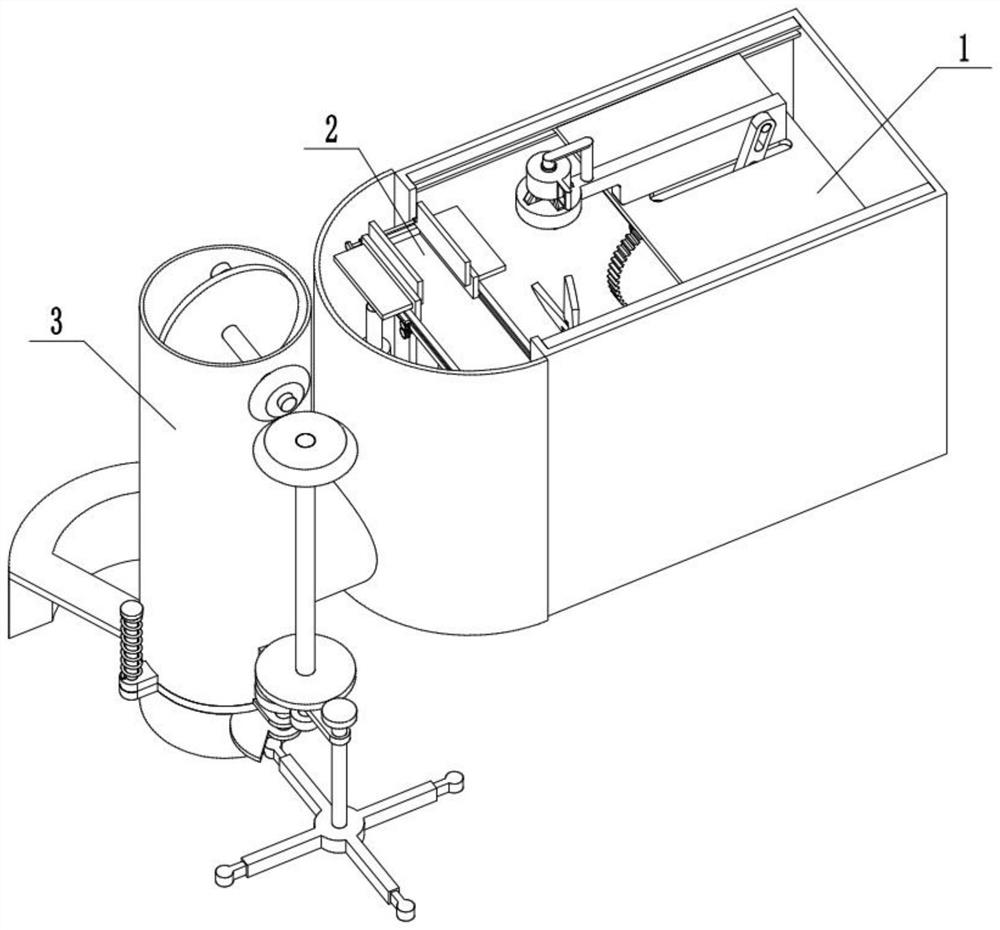

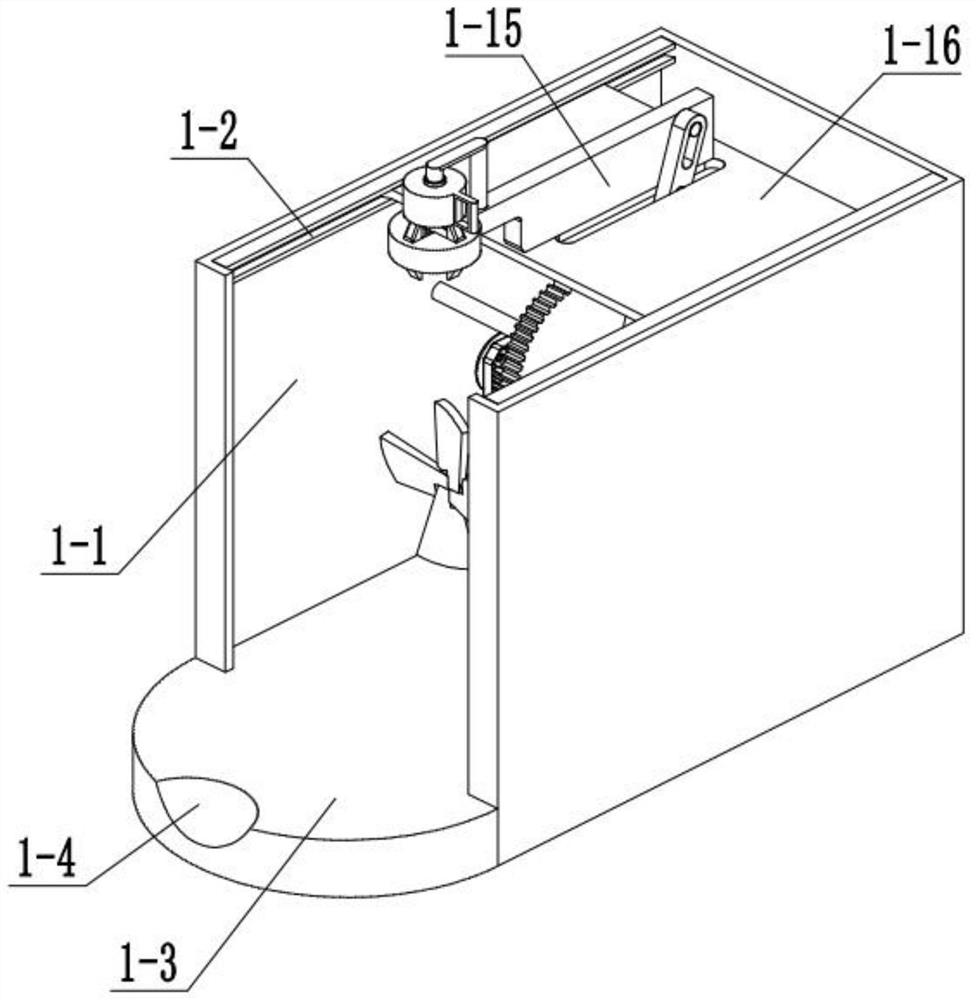

[0029] Combine below Figure 1-15 Describe this embodiment, a planer that is convenient for planing any plane of materials, including a planing assembly 1, a clamping assembly 2 and an iron filings pressing assembly 3, the planing assembly can drive the cutter to reciprocate to plan the material , the tool is easy to replace, the clamping assembly can clamp any shape of material, the processing plane can be adjusted conveniently, the position of the material can be adjusted according to the reciprocation of the tool, and it is easy to plan. Chips are collected and pressed into blocks, which is convenient for collection and processing, and avoids waste of resources.

specific Embodiment approach 2

[0030] Combine below Figure 1-15Describe this embodiment, this embodiment will further explain Embodiment 1, place the material to be planed in the angle adjustment disc 2-4, turn the knob 2-13, the knob 2-13 drives the two-way threaded shaft 2-14 to rotate, and the two-way The threaded shaft 2-14 is axially limited by the intermittent slide plate 2-11, and the two-way threaded shaft 2-14 is provided with two threads with opposite directions of rotation. The two clamping plates 2-12 are threaded, and the two-way threaded shaft 2-14 drives the two clamping plates 2-12 to approach each other to clamp the material. The hydraulic cylinder 2-1 is connected to the hydraulic system, and the hydraulic system can control the hydraulic pressure separately. Cylinder 2-1 oil injection and oil output, the hydraulic system respectively controls the oil injection and oil output to the hydraulic cylinders 2-1 on both sides to drive the telescopic rod 2-2 to shrink and stretch, and the height...

specific Embodiment approach 3

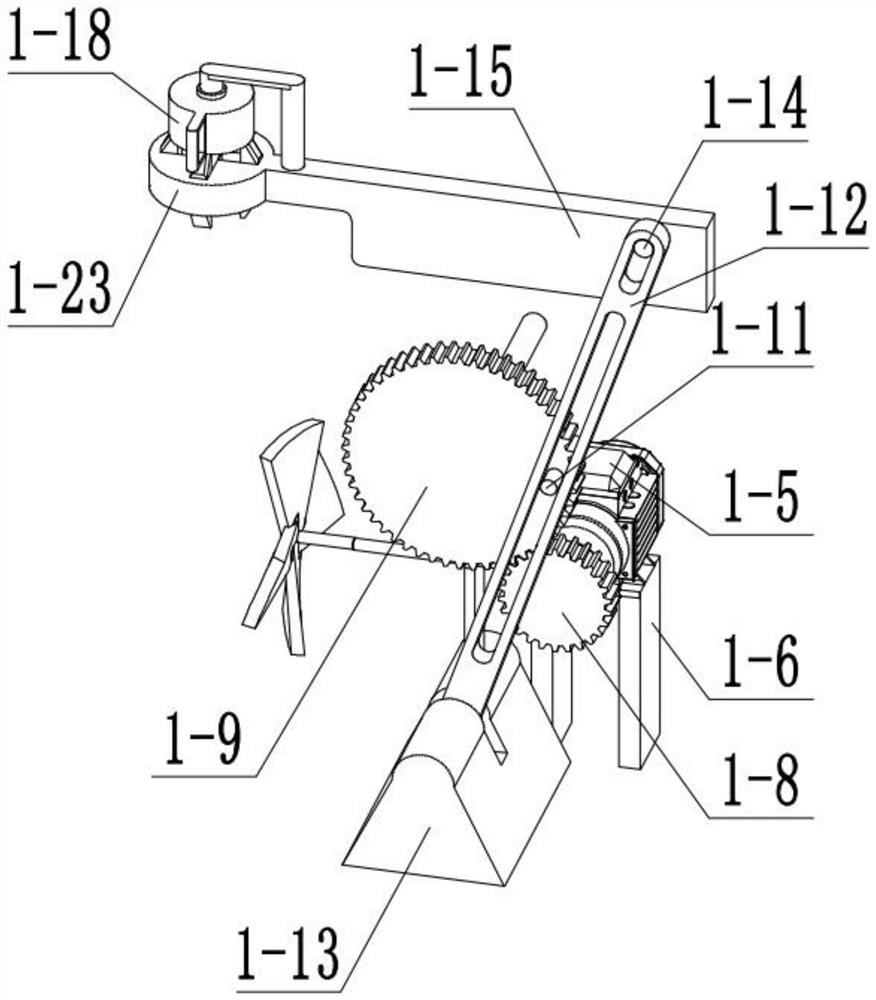

[0031] Combine below Figure 1-15 Describe this embodiment. This embodiment will further explain Embodiment 1. After the clamping is completed, place the tool between the four tool holders 1-21, turn the handle 1-17, and the handle 1-17 drives the threaded sleeve 1-18 Turn, the threaded sleeve 1-18 moves downward under the action of threaded connection with the threaded shaft 1-19, and the threaded sleeve 1-18 slides inwardly along the clamp sliding chamber 1-23 while moving the four tool holders 1-21 , the shrapnel 1-22 shrinks, the four tool holders 1-21 clamp the tool, turn on the motor 1-5, the motor 1-5 drives the motor shaft 1-7 to rotate, the motor shaft 1-7 drives the gear I 1-8 to rotate, the gear Ⅰ1-8 drives gear Ⅱ1-9 to rotate, gear Ⅱ1-9 drives gear Ⅱ bump 1-11 to rotate, gear Ⅱ bump 1-11 drives swing connecting rod 1-12 to rotate around the hinge shaft with connecting rod lug 1-13 Reciprocating swing, swing connecting rod 1-12 drives swing bump 1-14 to move, swing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com