Automatic planer capable of processing one-face, two-face or short wood slide with angle

An angle, planer technology, applied in wood processing appliances, processing machines for manufacturing flat surfaces, manufacturing tools, etc., to achieve the effects of stable quality, high safety, and low equipment failure rate

Active Publication Date: 2010-09-29

重庆谭木匠工艺品有限公司

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003]1) The open feeding channel has the possibility of causing personal injury;

[0004]2) The dust generated by planing will pollute the environment;

[0005]3) When the amount of planing increases or the tool becomes blunt, the motor is easily damaged by overload

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

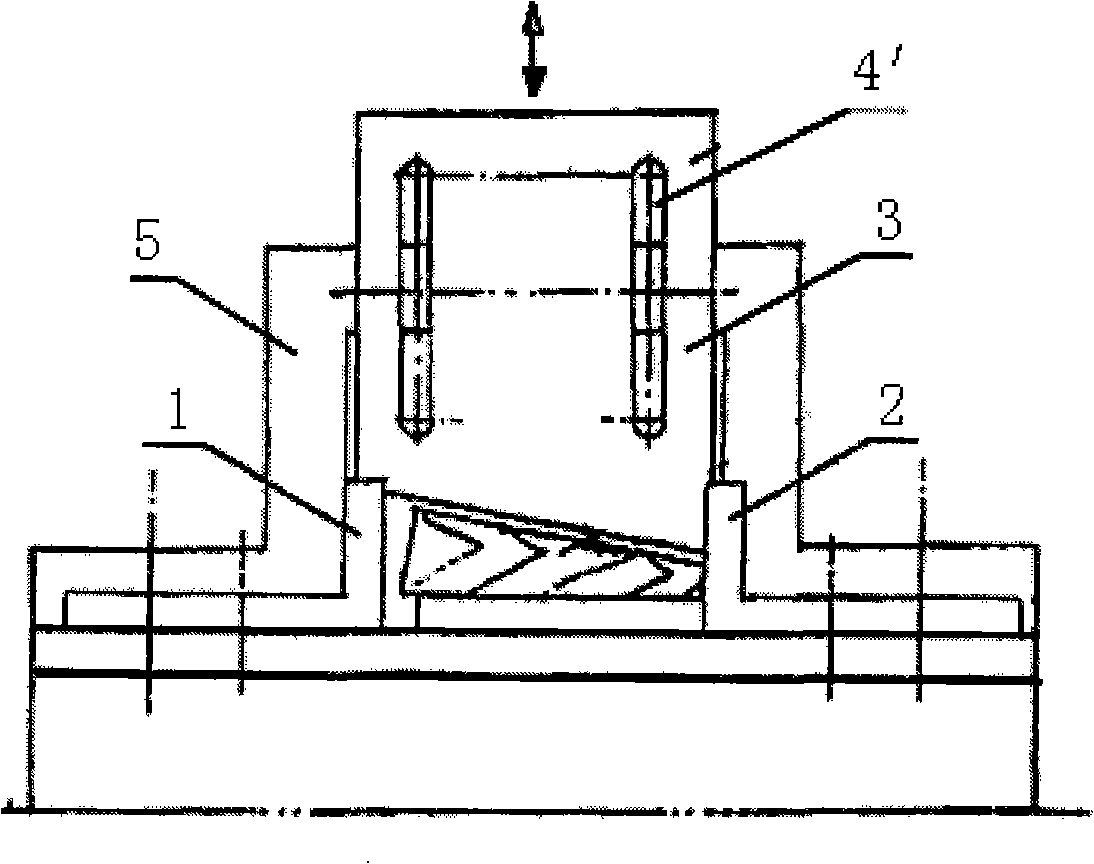

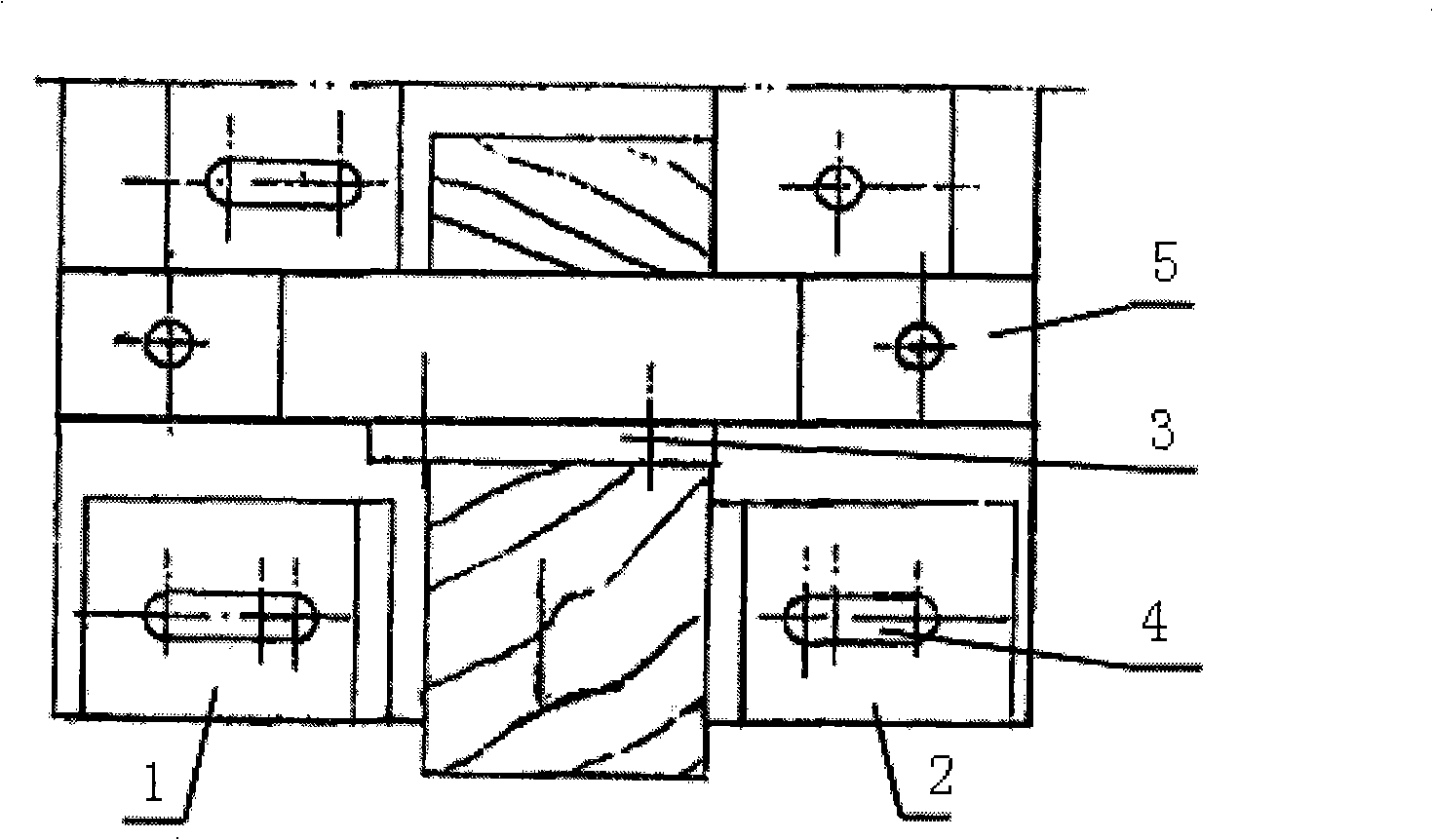

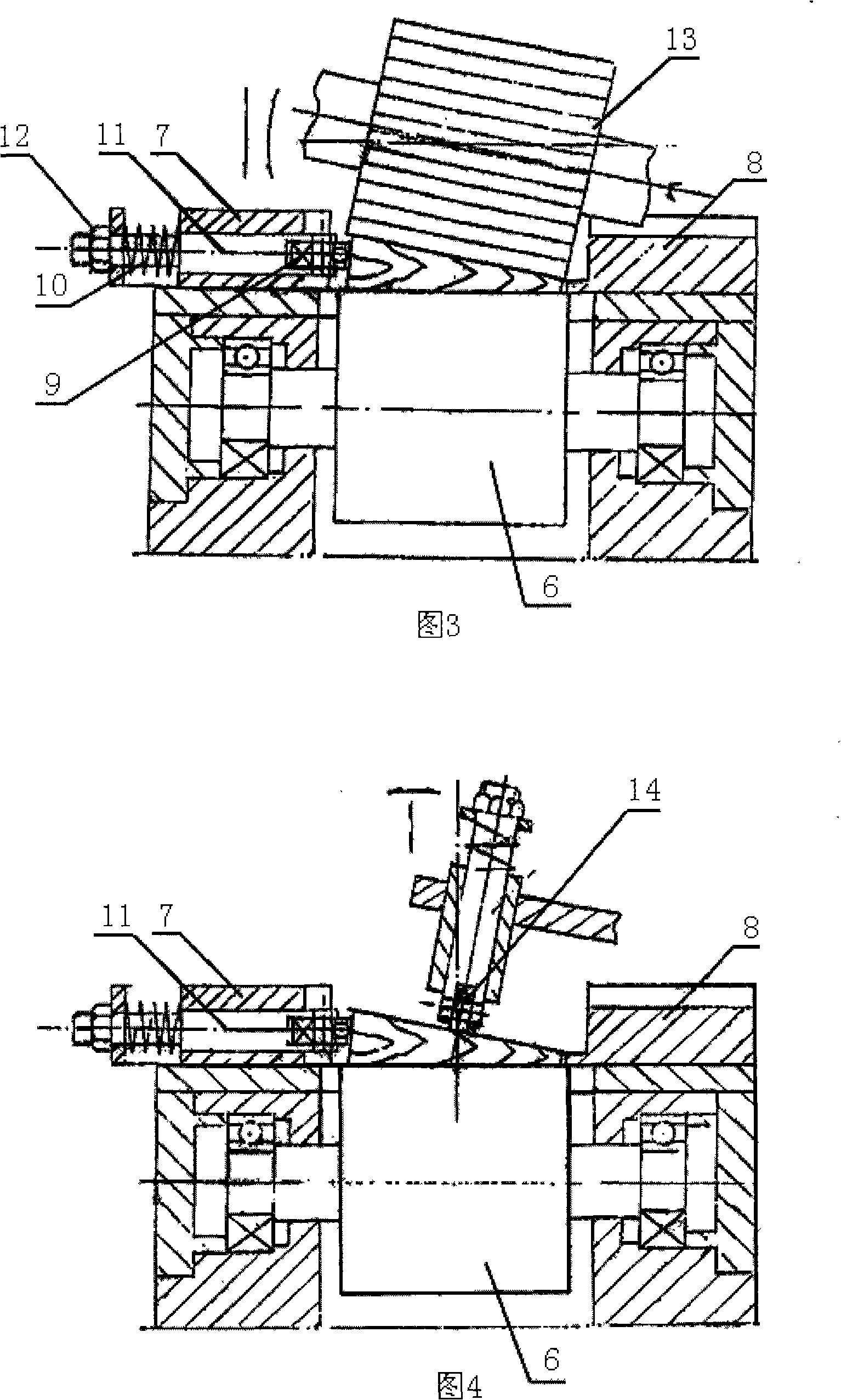

The invention discloses an automatic planer capable of simultaneously processing one-sided, two-sided or angular short and small piece wood, which mainly comprises a worktable, a drive motor and an upper planning tool and a lower planning tool arranged on the worktable. A control door mechanism consisting of a left control panel, a right control panel and an upper control panel is arranged at a feeding opening of the worktable; a delivery tug is arranged below the worktable; the left side and the right side of the worktable are provided with a left occulting bar and a right occulting bar respectively so as to form a closed delivery passage, wherein the a transverse compress roller wheel on the left occulting bar is provided with a spring, a directional traveler and a nut for adjusting thecompress distance; and a delivery ratchet wheel capable of adjusting angle, compress force and up-down distance is arranged above the delivery passage. The automatic planer solves the problem that the prior equipment cannot process short and small piece wood, and can continuously and efficiently manufacture products with stable size, angle and quality; and the equipment has low fault rate and high safety, does not damage the bodies of operators, and has quite convenient use, debugging and maintenance.

Description

technical field [0001] The present invention relates to wood processing equipment, specifically an automatic planer for processing one-sided, two-sided or angled short wood chips. Background technique [0002] Existing woodworking single-sided planers, pressure planers, and four-sided planers can only process large-sized wood chips. Due to the lack of adjustable feeding control mechanisms and feeding mechanisms, they can only process wood chips with a length of more than 200mm, and cannot process wood chips with a minimum length of 80mm. wood chips. In addition, there are the following defects: [0003] 1) The open feeding channel has the possibility of causing human injury; [0004] 2) The dust generated by planing will pollute the environment; [0005] 3) When the amount of planing increases or the tool becomes blunt, the motor is easily overloaded and damaged. Contents of the invention [0006] In order to solve the above problems and defects, the present inventi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B27C1/08B27C1/12B27C1/14B27G3/00

Inventor 姚时俭

Owner 重庆谭木匠工艺品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com