Double-sided planer with oppositely arranged planer tools

A double-sided planer and planer technology, which can be applied to workpiece feeding devices, processing machines for manufacturing flat surfaces, and wood processing appliances, etc., can solve problems such as increased production costs, inconsistent surface thickness, and reduced board utilization rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

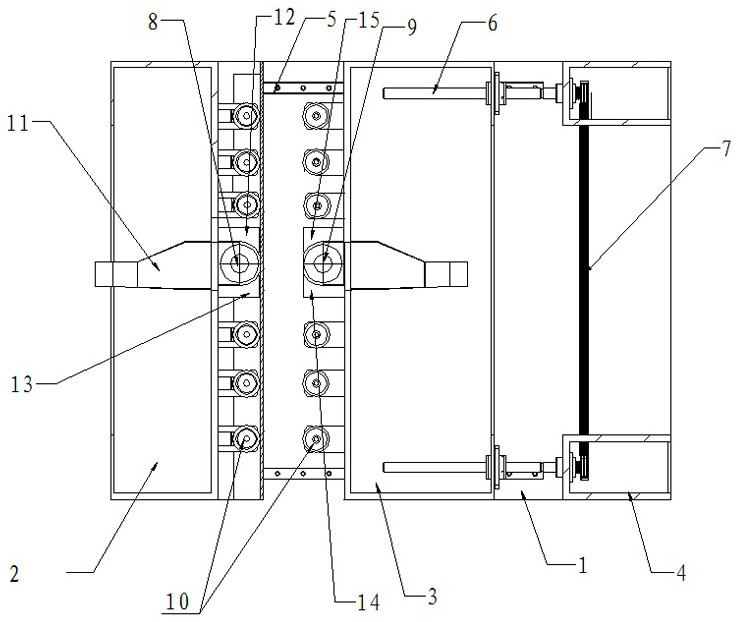

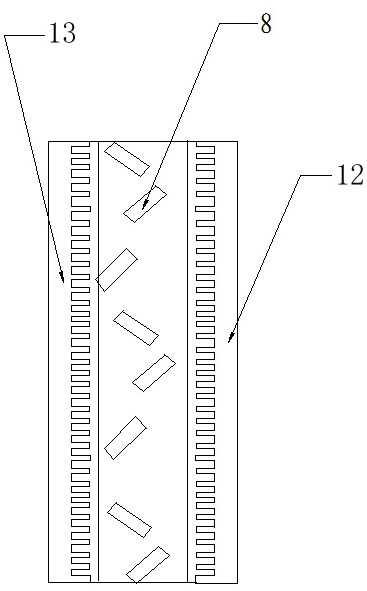

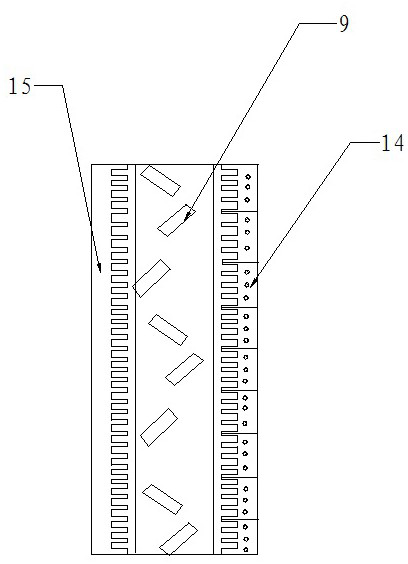

[0017] Refer to attached Figure 1-3 , the planer corresponds to the set double-sided planer, such as Figure 1 to Figure 3 , including the base 1, the left end of the base 1 is equipped with a fixed planer body 2, the right end is equipped with a fixed bracket 4, the middle position of the upper part of the base 1 is equipped with a slide rail 5, and the slide rail 5 is equipped with a mobile planer body 3, and the mobile planer body 3 can move left and right on the slide rail 5, the mobile planer body 3 is connected with the fixed bracket 4 through 4 adjustment screws 6, and the 4 adjustment screw rods 6 are connected with the motor through the chain 7 and drive the adjustment screw rod 6 to rotate, so that the mobile planer body 3 is left or right Move to adjust the thickness of planed board. The two sides corresponding to the fixed planer body 2 and the mobile planer body 3 are respectively provided with a planer A8 and a planer B9, and the planer A8 and the planer B9 are...

Embodiment 2

[0021] On the basis of Example 1, the planer A8 and the planer B9 are changed to be horizontally arranged and installed correspondingly up and down. This planing method is a horizontal double-sided planer, which has the same planing effect on the board as the vertical double-sided planer in Embodiment 1, and different users can choose double-sided planers with different planing methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com