Numerical control planing and polishing combined machining method for special-shaped blades of super-huge type water ring vacuum pump impeller and equipment

A water ring vacuum pump and composite processing technology, which is applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., to achieve the effects of improving clamping accuracy, processing accuracy and processing efficiency, and processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

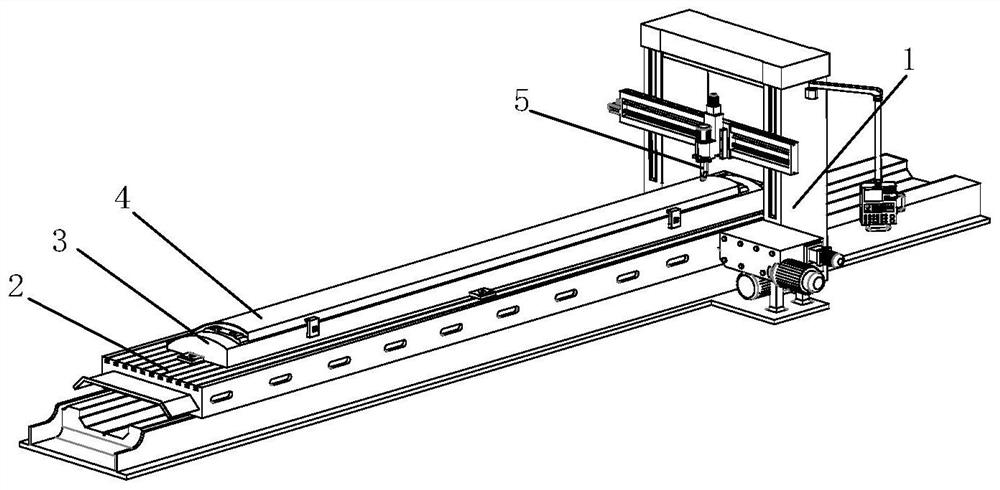

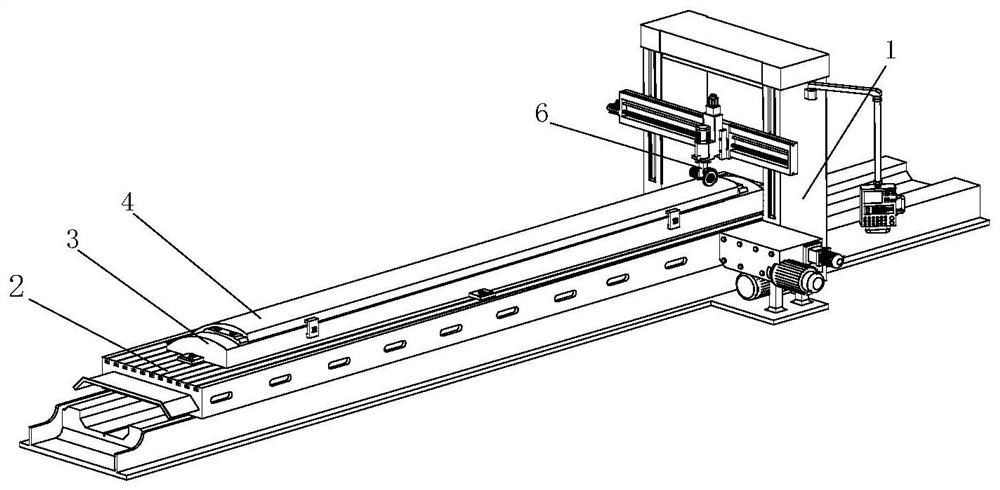

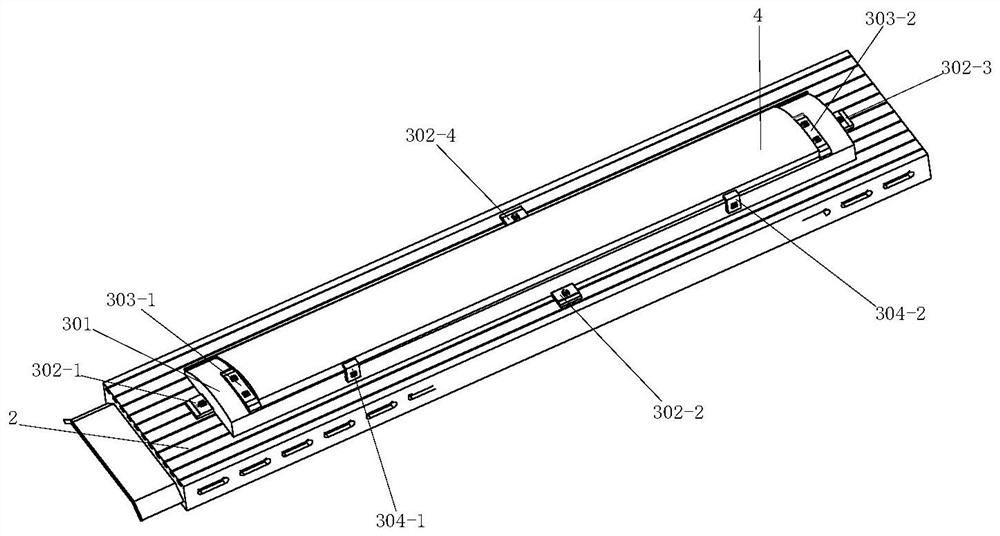

[0035] Such as figure 1 As shown, the schematic diagram of the convex planing processing principle of the impeller blade of the present invention, the blade convex surface positioning fixture 3 is fixed on the machine tool table 2, the special-shaped blade blank 4 is clamped on the blade convex surface positioning fixture 3, and the blade convex surface positioning fixture 3 has a The profile of the special-shaped blade blank 4 has a positioning boss with the same shape and profile, and the blade positioning boss is milled out on the side. The blade convex surface positioning fixture 3 is used to clamp the special-shaped blade blank 4; the CNC program is written into the gantry CNC planer 1, and the planer is used The circular planer 5 on the top processes the convex surface of the thin-walled complex spline-shaped line variable-thickness bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com