Cutting method of LED chip

A technology of LED chip and cutting method, applied in the direction of fine working devices, electrical components, circuits, etc., can solve the problems of edge chipping, ablation and twinning, and achieve the effect of avoiding ablation, easy implementation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

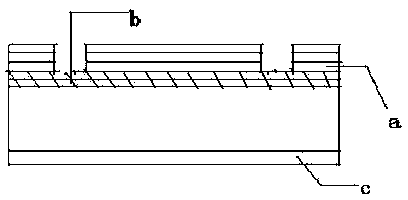

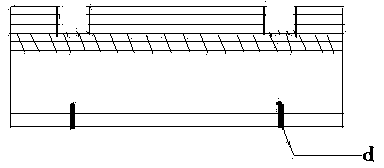

[0018] A method for cutting LED chips is provided, see FIG. 2 . Proceed as follows:

[0019] (1) Chip preparation: GaN-based semiconductor structure layer a is epitaxially grown on a silicon substrate with a thickness of 5 μm, and there are multiple layers of thick metal b and back metal c in the trench, see Figure 2 (I) ;

[0020] (2) Laser scribing: Paste the LED chips on the white film (model spv-224 160mm×100m) with the front facing down and the substrate facing up. It is required that there are no air bubbles between the chip and the white film. Put it on the carrier disk of the dicing machine, requiring the chip to be on the top and the film to be on the bottom. Adjust the level of the chip and determine the cutting range and laser route. Focus the 355nm ultraviolet laser emitted by the laser on the position of the dissociation groove on the upper surface of the LED chip through a corrected optical path. For scribing, adjust the laser frequency to 50-150kHz, the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com