Diamond saw blade and manufacturing method thereof

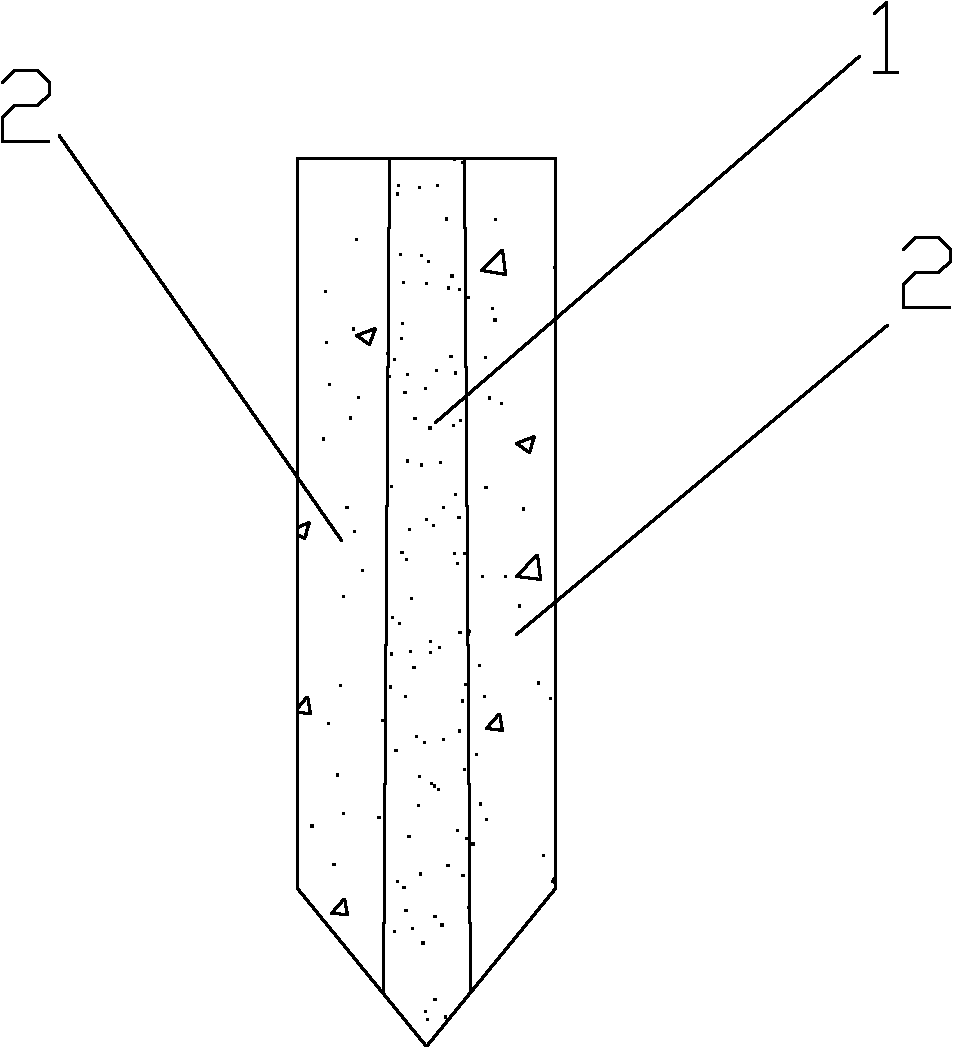

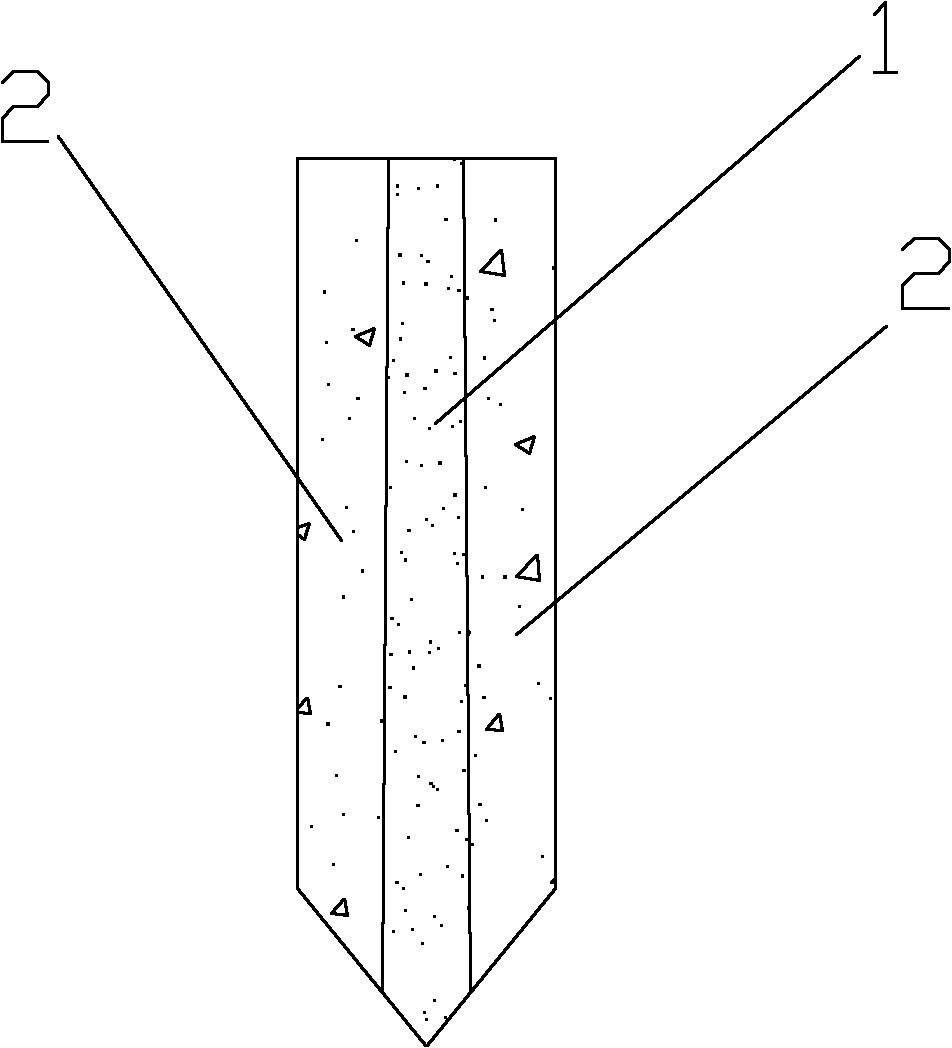

A diamond saw blade and diamond technology, which is applied in the direction of sawing machine tool manufacturing, manufacturing tools, metal sawing equipment, etc., can solve the problems of difficult installation and cutting, expensive, and many edge chipping, and achieve low manufacturing cost and fast cutting speed , cutting sharp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

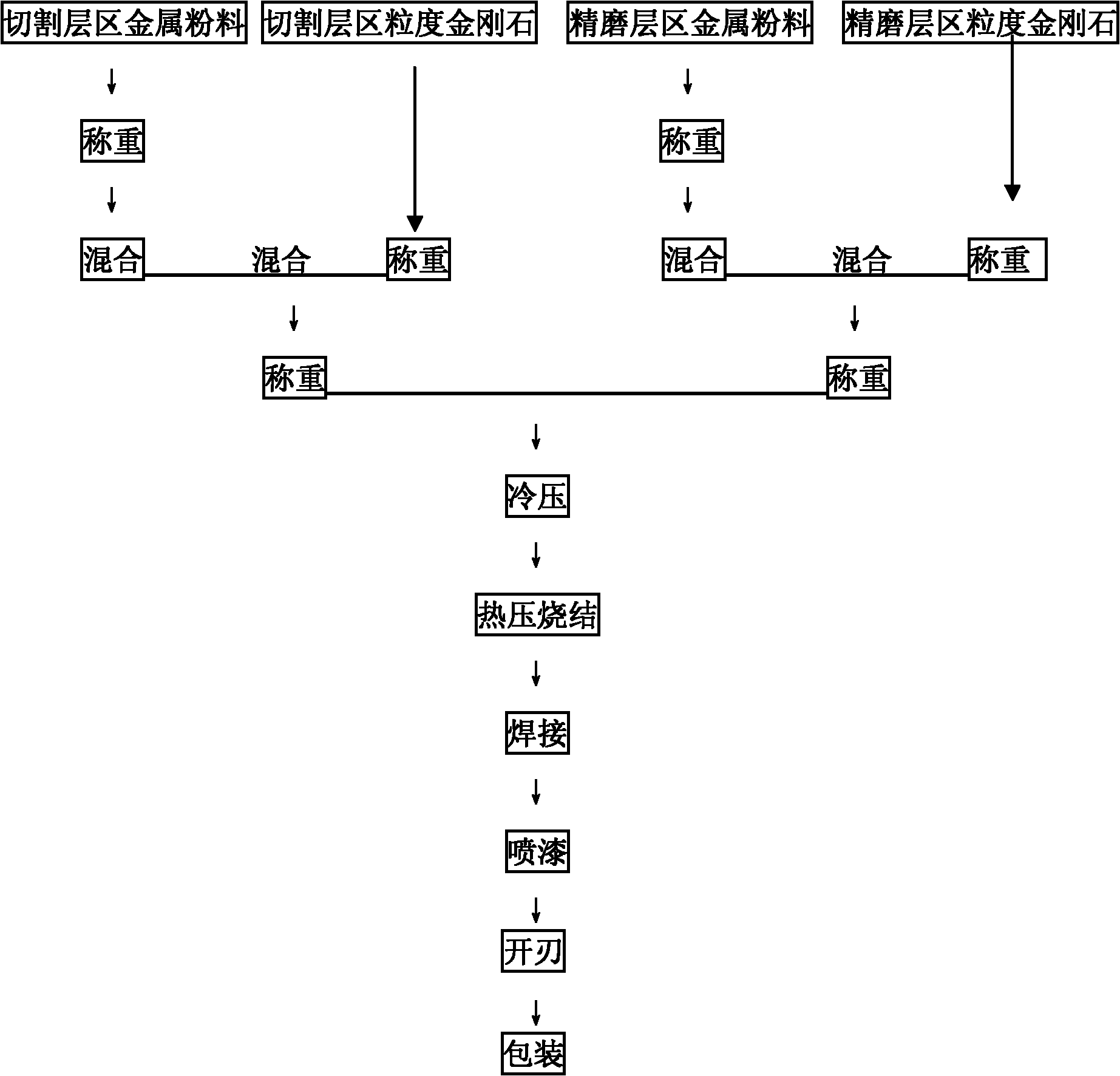

[0015] 1) According to the formula ratio of the cutting layer: the binder is 30% by mass of cobalt, 40% by mass of alloy powder with a ratio of copper to tin of 85:15, 20% by mass of iron, and 2% by mass of chromium. , Weigh the weight of various metal powders;

[0016] 2) Mix the above powders in a ball mill to make the metal powders evenly mixed;

[0017] 3) Weigh according to the formula ratio of diamond: the diamond grade is SMD25, the particle size is 40 / 50, and the concentration is 25%;

[0018] 4) Mix the metal powder in 2) and the diamond in 3) in a three-dimensional mixer to make them evenly mixed;

[0019] 5) According to the formula ratio of the fine grinding layer: the binder is 25% by weight of cobalt, 60% by weight of alloy powder with a ratio of copper to tin of 85:15, and 8% by weight of iron. Weigh various metal powders the weight of;

[0020] 6) Mix the above powders in a ball mill to make the metal powders evenly mixed;

[0021] 7) Weigh according to the formula rati...

Embodiment 2

[0028] 1) According to the formula ratio of the cutting layer: the binder is 35% by mass of cobalt, 45% by mass of alloy powder with a ratio of copper to tin of 85:15, 25% by mass of iron, and 3% by mass of chromium. , Weigh the weight of various metal powders;

[0029] 2) Mix the above powders in a ball mill to make the metal powders evenly mixed;

[0030] 3) Weigh according to the diamond formula ratio: the diamond grade is SMD25, the particle size is 40 / 50, and the concentration is 30%;

[0031] 4) Mix the metal powder in 2) and the diamond in 3) in a three-dimensional mixer to make them evenly mixed;

[0032] 5) According to the formula ratio of the fine grinding layer: the binder is 30% by mass of cobalt, 65% by mass of alloy powder with a ratio of copper to tin of 85:15, and 12% by mass of iron. Weigh various metal powders the weight of;

[0033] 6) Mix the above powders in a ball mill to make the metal powders evenly mixed;

[0034] 7) Weigh according to the formula ratio of dia...

Embodiment 3

[0041] 1) According to the formula ratio of the cutting layer: the binder is 32% by mass of cobalt, 41% by mass of alloy powder with a ratio of copper to tin of 85:15, 24% by mass of iron, and 2% by mass of chromium. , Weigh the weight of various metal powders;

[0042] 2) Mix the above powders in a ball mill to make the metal powders evenly mixed;

[0043] 3) Weigh according to the formula ratio of diamond: the diamond grade is SMD25, the particle size is 40 / 50, and the concentration is 26%;

[0044] 4) Mix the metal powder in 2) and the diamond in 3) in a three-dimensional mixer to make them evenly mixed;

[0045] 5) According to the formula ratio of the fine grinding layer: the binder is 32% by mass of cobalt, 63% by mass of alloy powder with a ratio of copper to tin of 85:15, and 9% by mass of iron. Weigh various metal powders the weight of;

[0046] 6) Mix the above powders in a ball mill to make the metal powders evenly mixed;

[0047] 7) Weigh according to the formula ratio of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com