Brazing process of diamond saw blade

A technology of diamond saw blade and brazing process, which is applied in the direction of metal sawing equipment, metal processing equipment, sawing machine tools, etc., can solve the problems of many pores, low porosity, unstable product quality, etc., and achieve small thermal damage , effect enhancement, good wetting and wetting properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

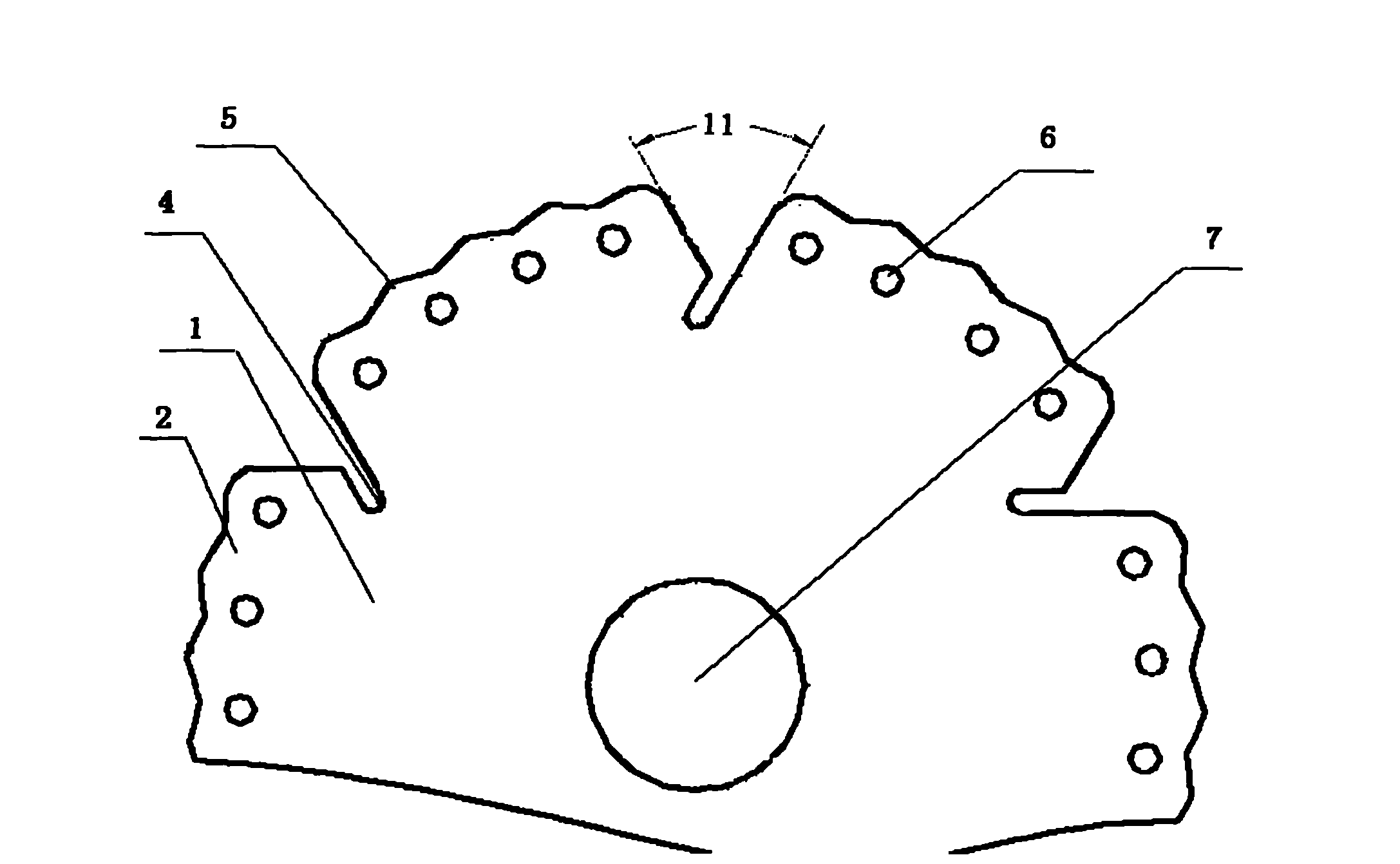

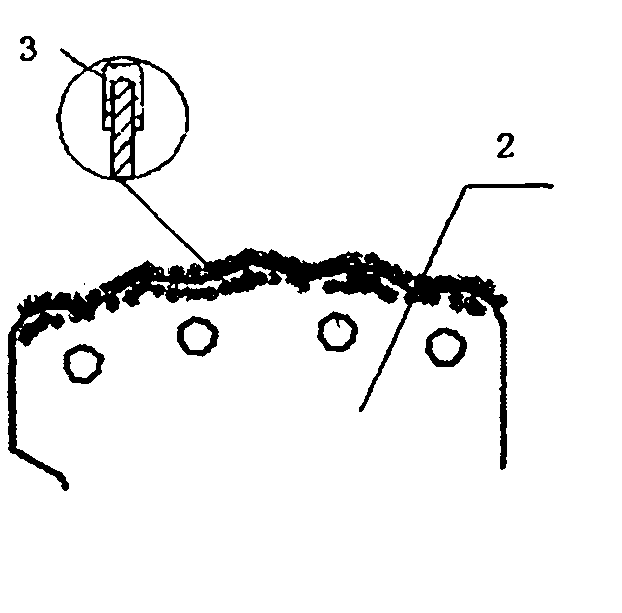

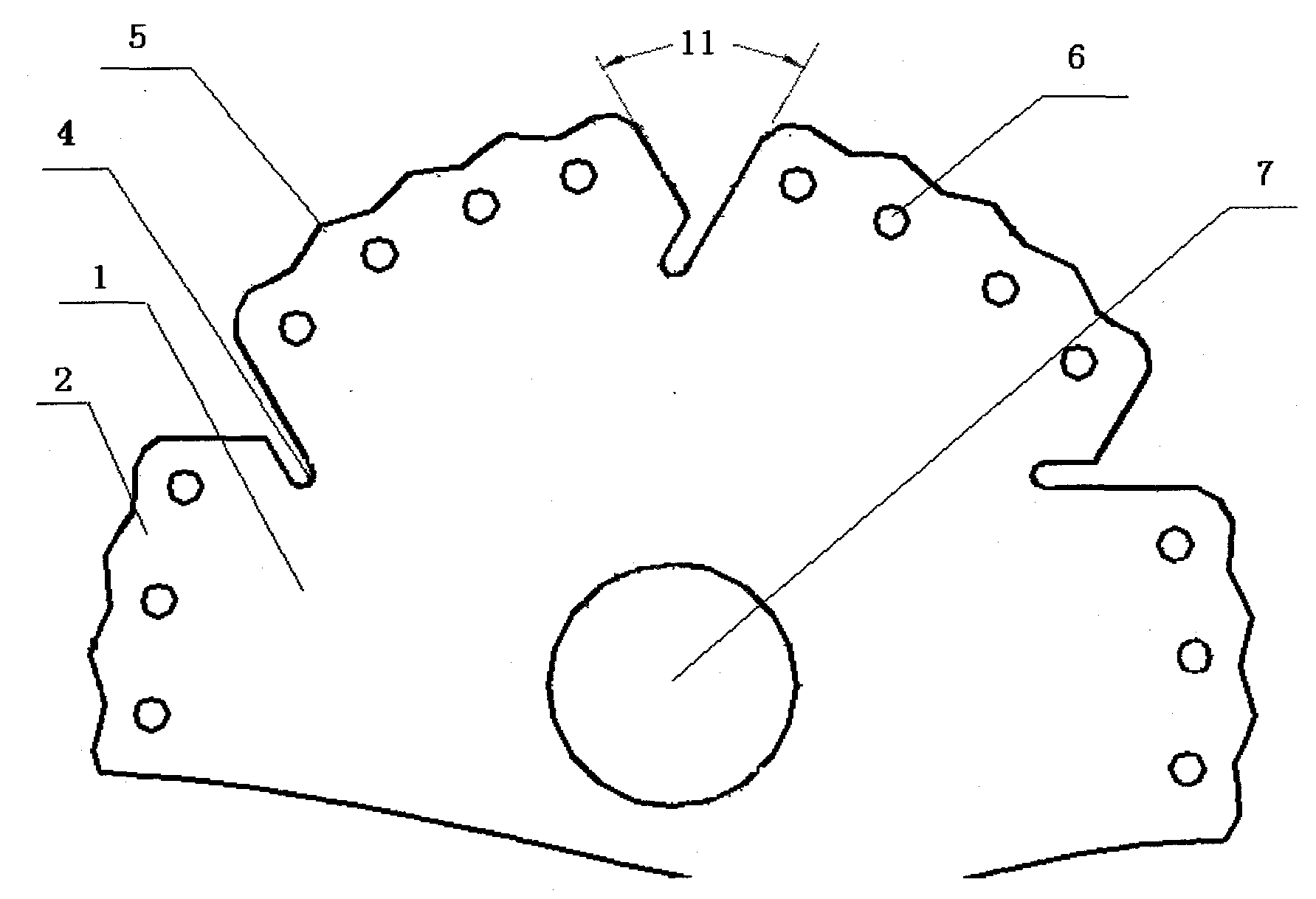

[0024] see Figure 1-2 , figure 1 It is a schematic plan view of a base body of a diamond circular saw blade according to an embodiment of the present invention. figure 2 It is a schematic plan view of a sawtooth segment with diamond abrasive grains according to an embodiment of the present invention. Depend on Figure 1-2 It can be seen that the diamond saw blade of this embodiment includes a disc-shaped saw blade base 1; six sawtooth sections 2 are evenly distributed on the edge of the saw blade base, and chip pockets 4 are arranged between each sawtooth section, and each sawtooth section There are wavy sawtooths on them, and the number of sawtooth peaks 5 is five. In addition, each sawtooth section is also provided with cooling holes 6. The number of cooling holes 6 on each sawtooth section is four. The number of cooling holes The diameter is 3 mm; the saw teeth are provided with diamond abrasive grains 3; the inclination angle 11 between two adjacent saw tooth segments...

Embodiment 2

[0026] The nickel-based solder powder of this embodiment is made of the following components according to the following ratio: Cu: 10.3wt%, Mn: 17.2wt%, Ti: 4.5wt%, Al: 7.2wt%, Sn: 2.2wt%, The balance is Ni. The preparation method is as follows:

[0027] According to the stated ratio, put the Cu, Mn, Ti, Al, Sn and Ni raw materials in the smelting furnace, and heat them to 1250°C under the pressure of 5 MPa to melt the raw materials; then fill the powder collector with Inject high-purity argon; use high-purity argon to atomize the melted raw materials, and the atomization pressure is 4MPa to obtain nickel-based brazing powder. The shape of the obtained powder is spherical, the particle size is less than 200 μm, and the melting point is 970 ° C.

Embodiment 3

[0029] The nickel-based solder powder of this embodiment is made of the following components according to the following ratio: Cu: 12.8wt%, Mn: 21.5wt%, Ti: 7.2wt%, Al: 9.8wt%, Sn: 3.2wt%, The balance is Ni. The preparation method is the same as in Example 2. The obtained nickel-based solder powder had a melting point of 940°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com