Biomimetic golden-embedded diamond drilling bit and its production

A diamond drill bit and a manufacturing method technology, applied in the direction of drill bits, earthwork drilling, drilling equipment, etc., can solve the problems of manpower and financial resource consumption, high unit footage cost, high processing cost, etc., to achieve improved product quality, high drilling speed, and economical The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

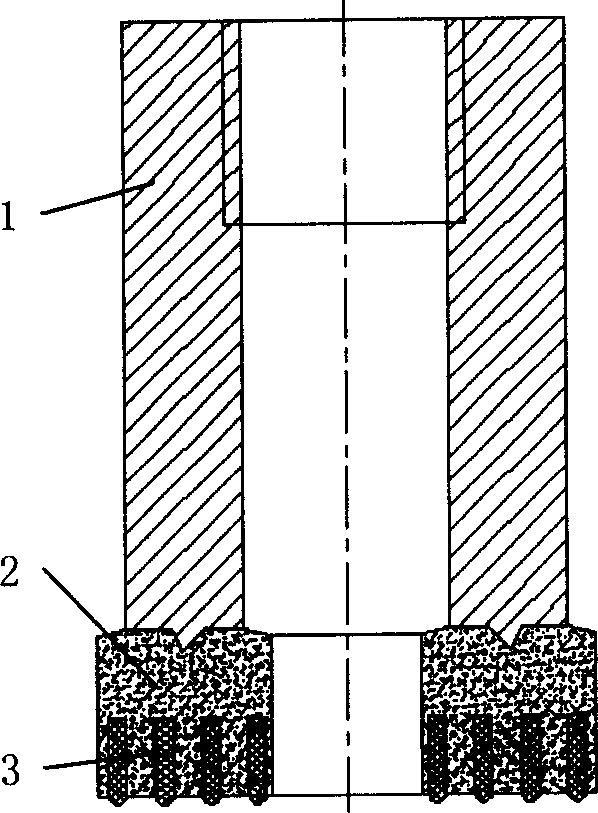

Embodiment 1

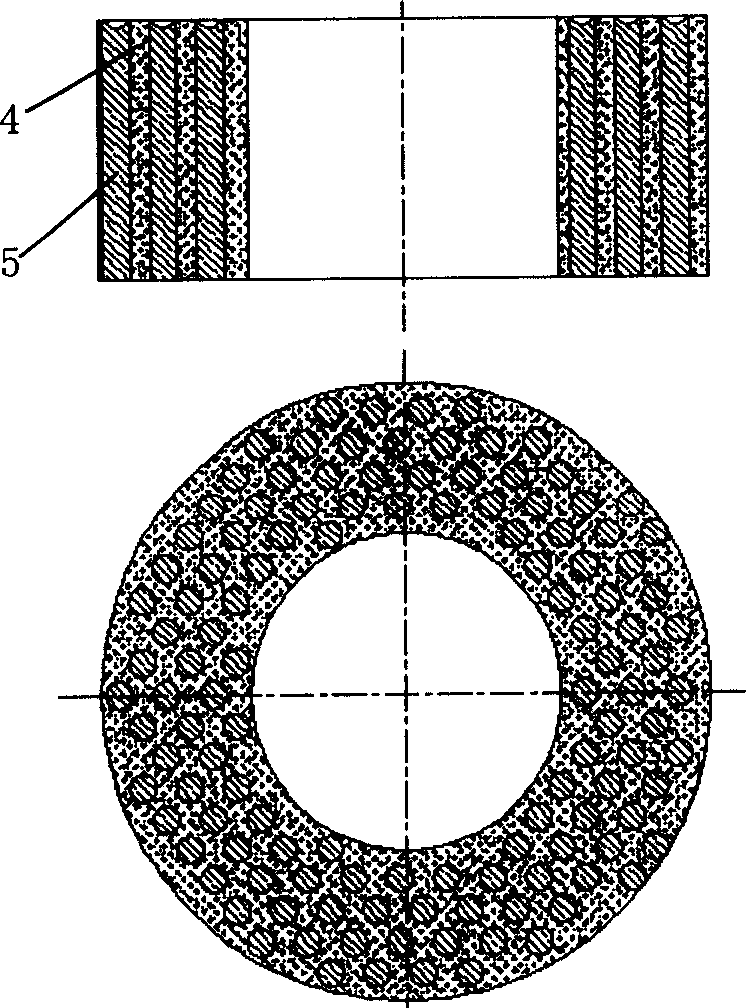

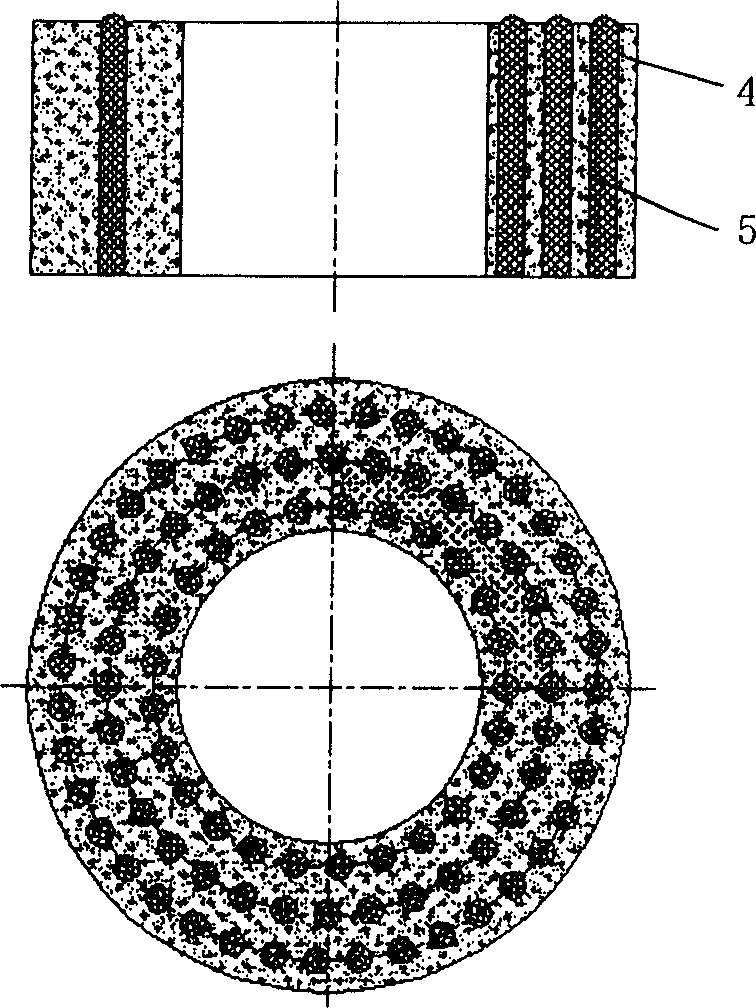

[0021] Take 20% of 80-mesh diamond and 50% matrix material by volume to fully mix into wear-resistant material 4, then mix 30% of quartz particles with a diameter of 2mm evenly, and make the quartz particles randomly distribute on the diamond according to the proportion of 15% of the bottom area. The mixture with the carcass material becomes the material of the working layer 3, and the material of the working layer 3 is evenly put into the graphite mold for compaction, and then the transition layer 2 is added on it, and then compacted, put into the steel body 1, and dried at the temperature 900℃, pressure at 160Kgf / Cm 2 It is hot-pressed under the condition of heat-preservation material, cooled slowly to room temperature in the heat preservation material, and the nozzle and thread are processed, which is the diamond-impregnated biomimetic drill bit. The specifications of drill bit, saw blade and grinding head can be designed arbitrarily.

Embodiment 2

[0023] Take 25% graphite by volume to make a graphite column with a diameter of 2mm and a length equal to the thickness of the working layer 3. The graphite column is concentrically fixed in a graphite mold in a ratio of 30% of the bottom area, and 25% of a 75-mesh diamond is taken. Fully mix with 50% carcass material to form wear-resistant material 4, fill in between graphite columns, add transition layer 2 on top after compaction, and then compact, put into steel body 1, after drying at temperature 950°C, pressure at 150Kgf / Cm 2 It is hot-pressed under the condition of heat-preservation material, cooled slowly to room temperature in the heat preservation material, and the nozzle and thread are processed, which is the diamond-impregnated biomimetic drill bit. The specifications of drill bit, saw blade and grinding head can be designed arbitrarily.

Embodiment 3

[0025] Get 25% diamond polycrystal by volume and make diameter be 2mm, length is equal to the diamond polycrystal pillar of working layer 3 thickness, by occupying the ratio of 40% of bottom area, diamond polycrystal pillar is fixed in the mold with rhombus distribution, takes by volume 70-mesh diamond 17% and 58% carcass material are fully mixed to form wear-resistant material 4, filled between diamond polycrystalline columns, after compaction, a transition layer 2 is added on top, and then compacted, put into steel body 1, after drying Temperature 1000℃, pressure 140Kgf / Cm 2 It is hot-pressed under the condition of heat-preservation material, cooled slowly to room temperature in the heat preservation material, and the nozzle and thread are processed, which is the diamond-impregnated biomimetic drill bit. The specifications of drill bit, saw blade and grinding head can be designed arbitrarily.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com