Marble cutting saw blade and preparation method thereof

A technology for cutting saws and marble, which is applied in the field of marble cutting saw blades and its preparation, which can solve the problems of high raw material cost, short service life, and high product cost of diamond saw blades, and achieve constant sawing flatness, low cost, and high cutting speed. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

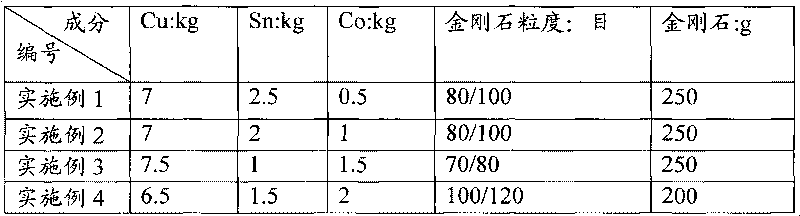

[0021] The invention starts from two aspects of matrix powder composition and saw blade preparation process, and focuses on improving cutting performance and reducing cost. The saw blade cutter head of the present invention adopts a copper base carcass, adds a small amount of tin powder, cobalt powder, and alloys carcass powder with a total weight of 10 kg, and the ratio of carcass powder and diamond is shown in Table 1. The composition involved in the concrete implementation case of the present invention is as shown in table 1:

[0022] Table 1

[0023]

[0024] Diamond tool of the present invention is manufactured according to the following steps:

[0025] (1) Mixing

[0026] Mix Cu, Sn, Co powder and diamond according to the weight ratio in Table 1 to obtain alloy carcass powder, and dry mix them in a three-dimensional mixer for 1 to 2 hours. In the mixing process, pour 5wt% granulating agent into the mixer, the composition of the granulating agent is: paraffin and ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com