Diamond bits and saw disc therewith

A diamond cutter head, diamond technology, applied in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve problems such as unreasonable structure, reduce chatter, improve cutting efficiency, and reduce noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1, a diamond cutter head with chip removal grooves.

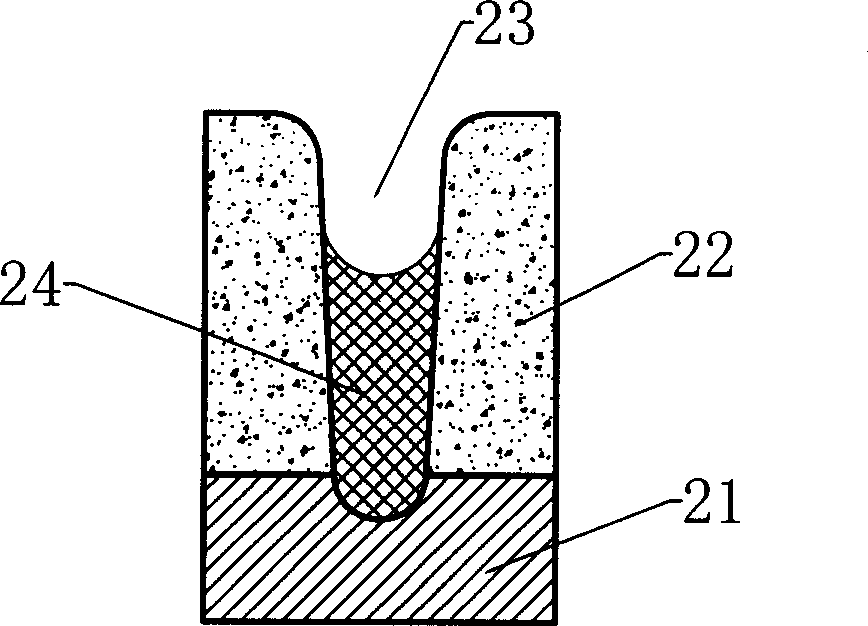

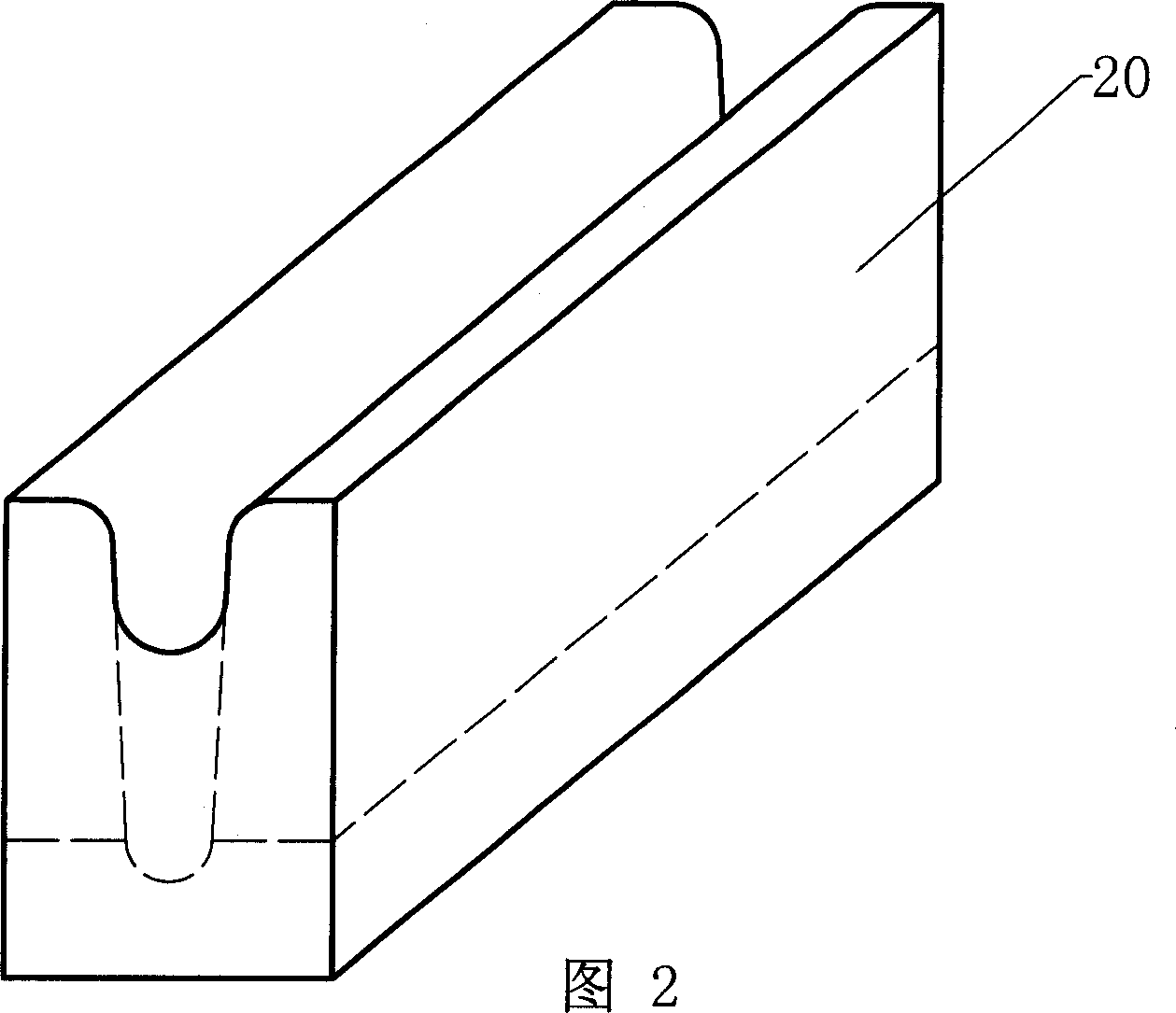

[0014] refer to figure 1 , Figure 2, the diamond cutter head is composed of a metal support 21 connected to the steel saw disc and a diamond matrix 22 arranged on the metal support. Groove 23, at the bottom of the chip removal groove, a graphite body 24 is arranged. In this example, the dimensions of the diamond cutter head are: length 25mm, height 7mm, width 6mm, upper bottom groove width 2.5mm, groove depth 5mm, diamond matrix height 4mm, graphite body height 3mm, chip removal groove The bottom of the graphite body and the upper part of the graphite body are provided with a circular arc transition surface.

[0015] The diamond cutter head described in this example can be processed by mold hot pressing, and the graphite body can be placed in the mold first, and then organically combined with the diamond cutter head after processing.

Embodiment 2

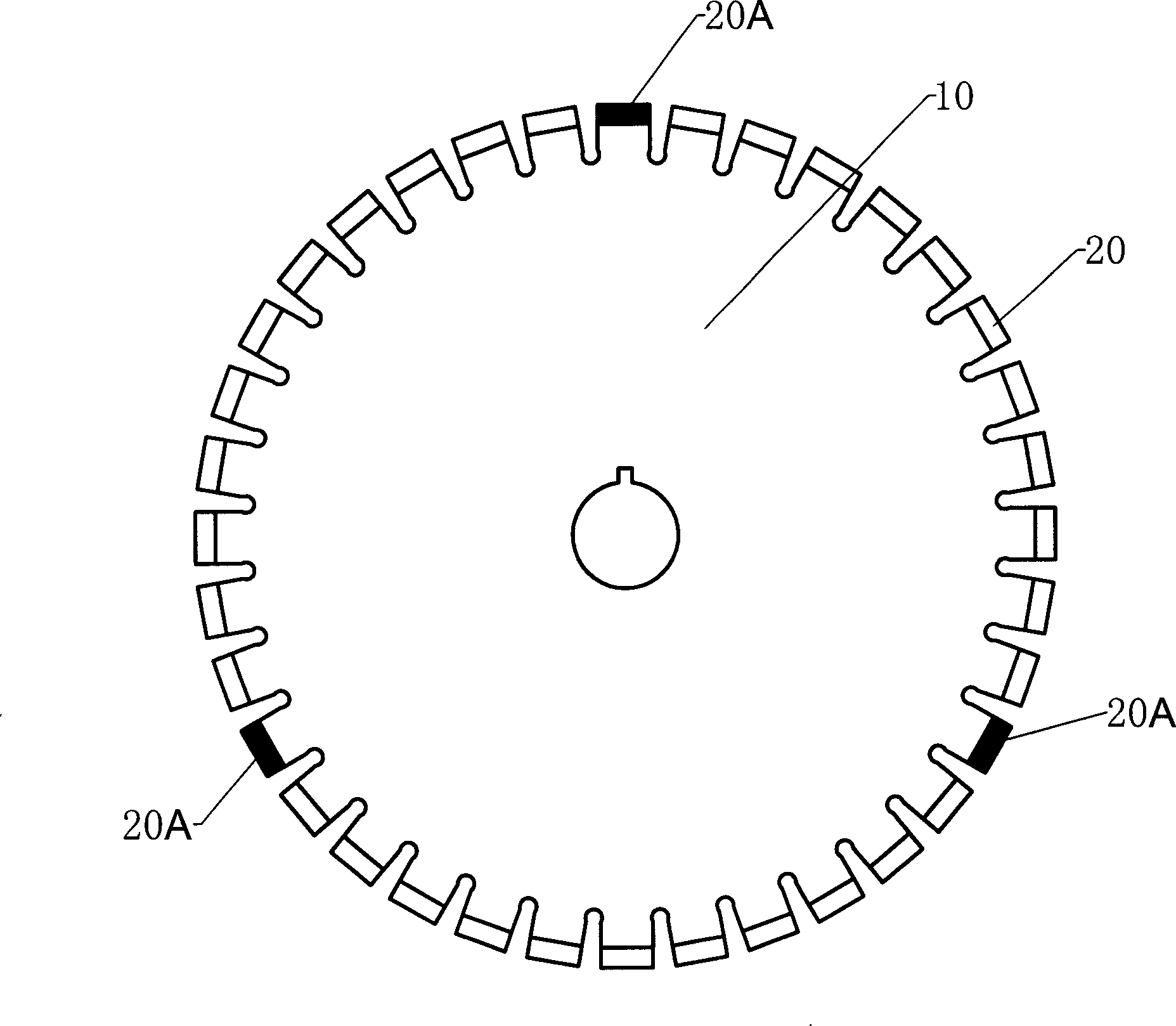

[0016] Embodiment 2, a diamond circular saw blade.

[0017] refer to image 3 , a diamond disc saw blade is composed of a disc steel substrate 10 and a diamond cutter head welded on its periphery. This example is provided with 36 diamond cutter heads, 33 of which adopt the diamond cutter head 20 with the chip removal groove described in embodiment 1, and the other 3 adopt the diamond cutter head 20A whose common cross section is rectangular. The cutter head and the diamond cutter head with chip removal grooves are uniformly welded alternately on the steel substrate 10 .

[0018] According to the test, compared with the existing diamond circular saw blade of the same specification, the diamond circular saw blade described in embodiment 2 can improve the working efficiency by more than 30%, and the processing cost of stone material per square meter can be reduced by 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com