Hot-pressing equipment for composite non-woven fabric

A technology of hot pressing equipment and non-woven fabrics, which is applied in the direction of lamination, lamination device, lamination auxiliary operation, etc., which can solve the problems of accelerating the heat dissipation of the heating roller, reducing the efficiency of hot pressing, and small contact area, so as to avoid excessive extrusion Pressure, prevent rigid collision, increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

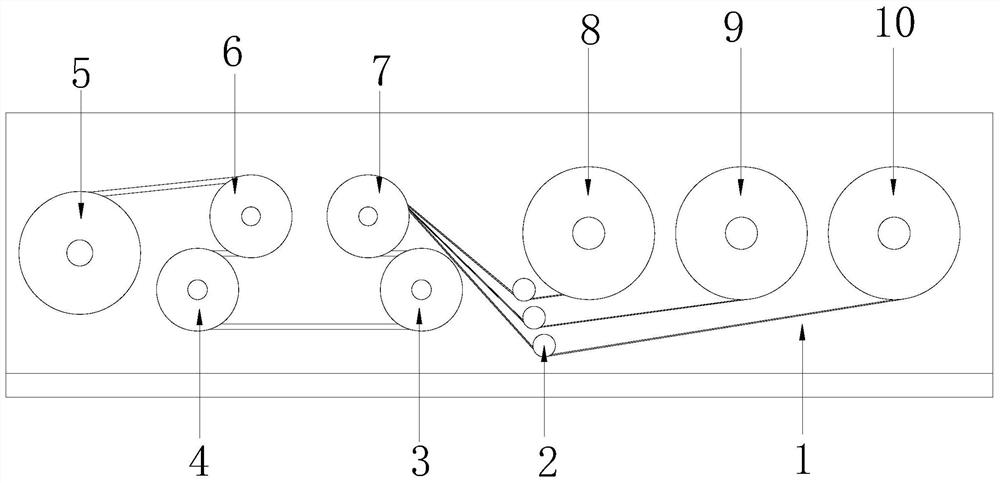

[0029] see Figure 1-9 , the present invention provides a technical solution for composite nonwoven hot pressing equipment: its structure includes an organism 1, No. 1 guide roller 2, No. 1 hot pressing roller 3, No. 3 guide roller 4, composite nonwoven fabric winding device 5 , No. 2 hot pressing roller 6, No. 2 guide roller 7, non-woven fabric roll 8, interlayer fabric roll 9, inner layer fabric cloth roll 10, and the body 1 is successively provided with non-woven fabric roll 8 and interlayer fabric roll 9 , inner layer fabric roll 10, the fabrics of described non-woven fabric roll 8, interlayer fabric roll 9, inner layer fabric roll 10 all contact No. 1 guide roller 2, and fabric and No. 3. Cooperate with No. 3 guide roller 4 and No. 2 hot pressing roller 6, and finally connect with composite non-woven fabric winding device 5.

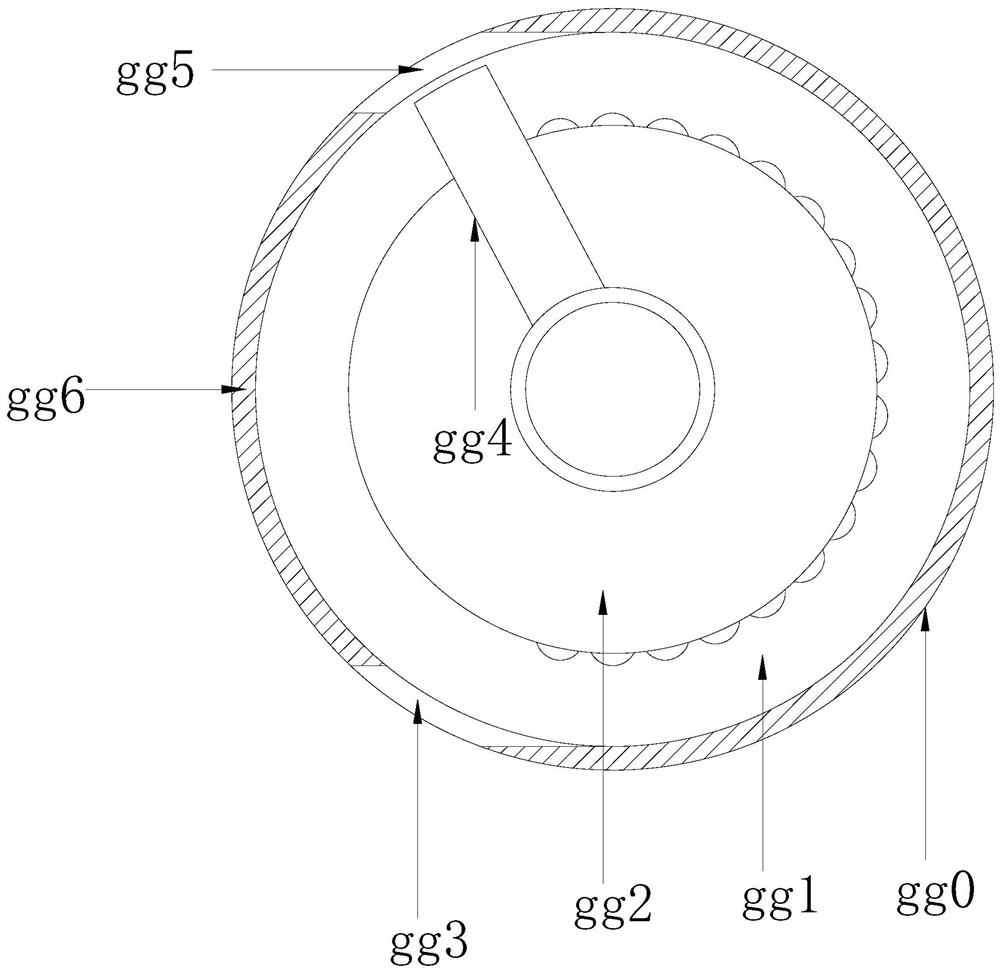

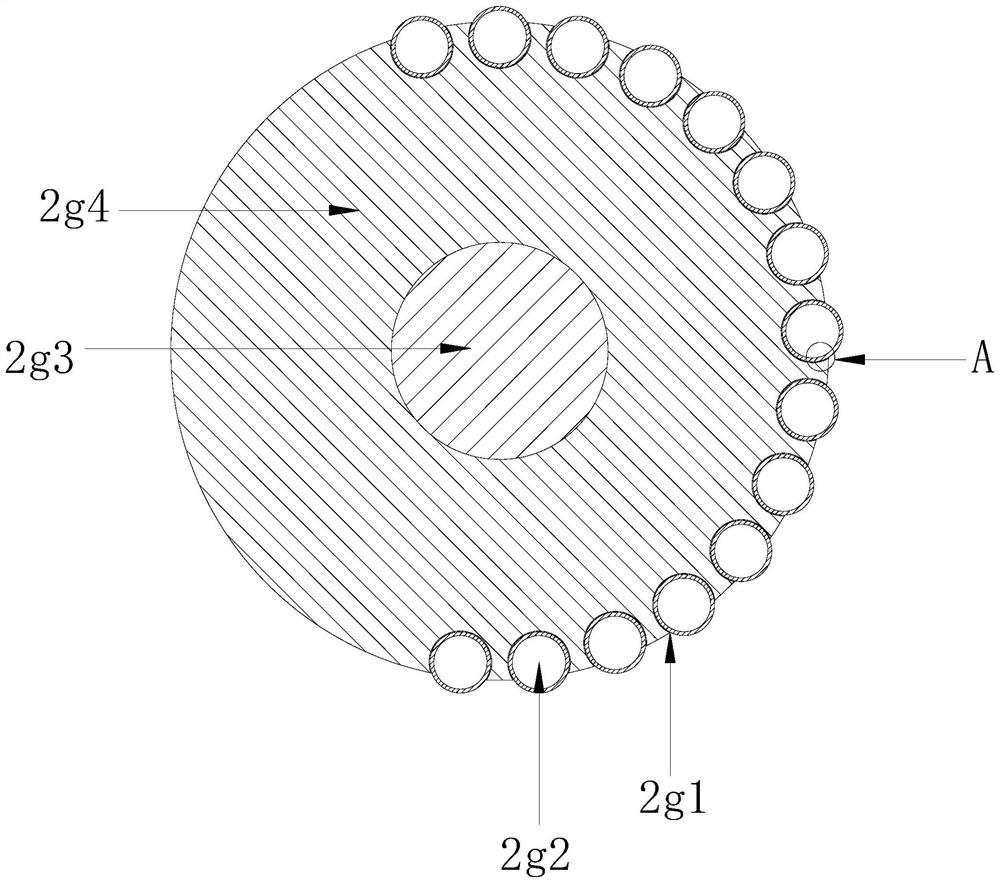

[0030] As a further optimization of the technical solution, the No. 1 hot pressing roller 3 has the same composition structure as the No. 2 hot pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com