New energy motor shell hot press mounting equipment

A motor housing and new energy technology, applied to household components, flat products, household appliances, etc., to achieve the effects of preventing damage, improving the quality of hot pressing, and improving the efficiency of hot pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

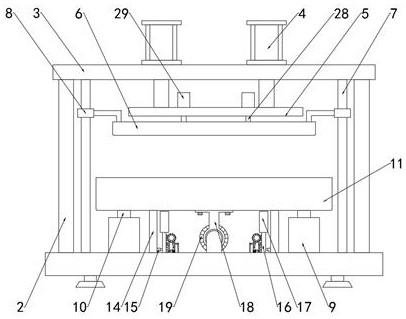

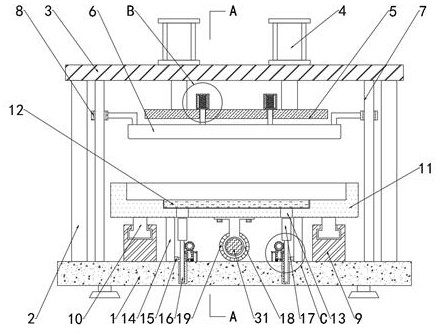

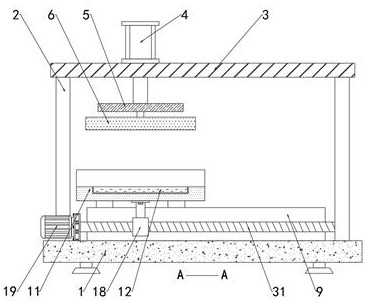

[0034] see Figure 1-5 , new energy motor housing thermal press assembly equipment, including a base 1, the upper end of the base 1 is provided with a column 2, the top of the column 2 is provided with a top plate 3, and the upper end of the base 1 is provided with symmetrically distributed guide rails 9, guide rails 9 Slider-10 is slidingly connected inside the slider-10, and the upper end surface of slider-10 is provided with a lower die 11, and the center of the lower end face of the lower die 11 is provided with a nut pair 18, and the inside of the nut pair 18 is screwed and connected with a screw 31. The end of the lead screw 31 is connected to the drive motor-19 installed on the base 1, the top plate 3 is provided with a cylinder 4, the telescopic end of the cylinder 4 is provided with a base plate 5, and the base plate 5 is connected with an upper platen 6 through a fixed rod 28 , the inside of the lower die 11 is embedded with a movable plate 12, the upper end surface ...

Embodiment 2

[0036] see Figure 1-5 , new energy motor housing thermal press assembly equipment, including a base 1, the upper end of the base 1 is provided with a column 2, the top of the column 2 is provided with a top plate 3, and the upper end of the base 1 is provided with symmetrically distributed guide rails 9, guide rails 9 Slider 10 is slidingly connected inside the slider 10, and the upper end surface of slider 10 is provided with a lower die 11, and the center of the lower end face of the lower die 11 is provided with a nut pair 18, and the inside of the nut pair 18 is screwed and connected with a screw 31. The end of the lead screw 31 is connected to the driving motor-19 installed on the base 1, the top plate 3 is provided with a cylinder 4, the telescopic end of the cylinder 4 is provided with a base plate 5, and the base plate 5 is connected with an upper platen 6 through a fixed rod 28 , the bottom of the fixed rod 28 is fixedly connected with the upper pressing plate 6, the...

Embodiment 3

[0038] see Figure 1-5, new energy motor housing thermal press assembly equipment, including a base 1, the upper end of the base 1 is provided with a column 2, the top of the column 2 is provided with a top plate 3, and the upper end of the base 1 is provided with symmetrically distributed guide rails 9, guide rails 9 Slider-10 is slidingly connected inside the slider-10, and the upper end surface of slider-10 is provided with a lower die 11, and the center of the lower end face of the lower die 11 is provided with a nut pair 18, and the inside of the nut pair 18 is screwed and connected with a screw 31. The end of the lead screw 31 is connected to the drive motor-19 installed on the base 1, the top plate 3 is provided with a cylinder 4, the telescopic end of the cylinder 4 is provided with a base plate 5, and the base plate 5 is connected with an upper platen 6 through a fixed rod 28 , the inside of the lower die 11 is embedded with a movable plate 12, the lower end surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com