Modified soybean aldehyde-free flame-retardant adhesive and preparation method thereof

A flame retardant adhesive and modification technology, applied in the field of modified soybean formaldehyde-free flame retardant adhesive and its preparation, can solve the problems of unsatisfactory flame retardant effect, fast drying time, high price, etc., and achieve good flame retardant effect , The effect of improving viscosity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

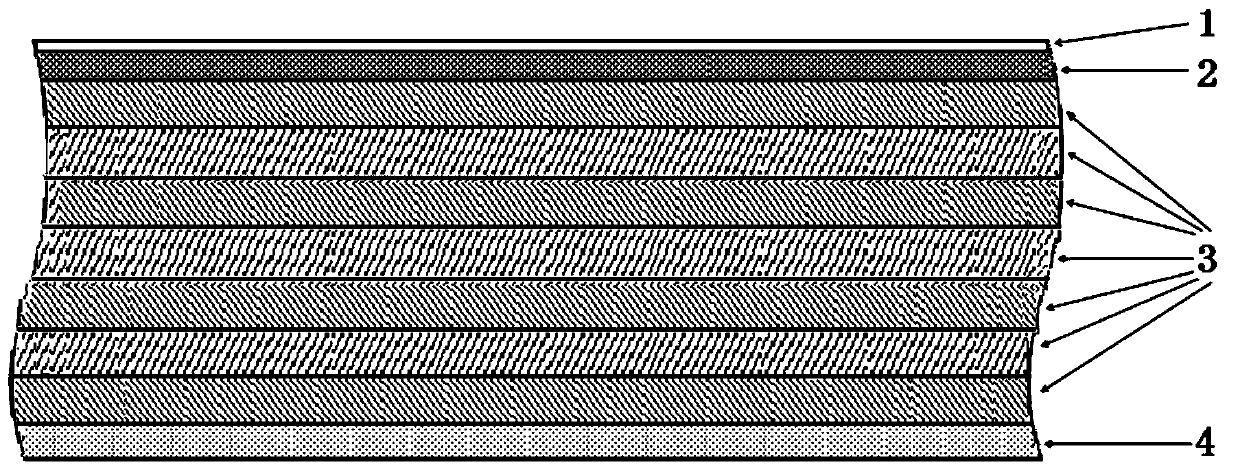

Image

Examples

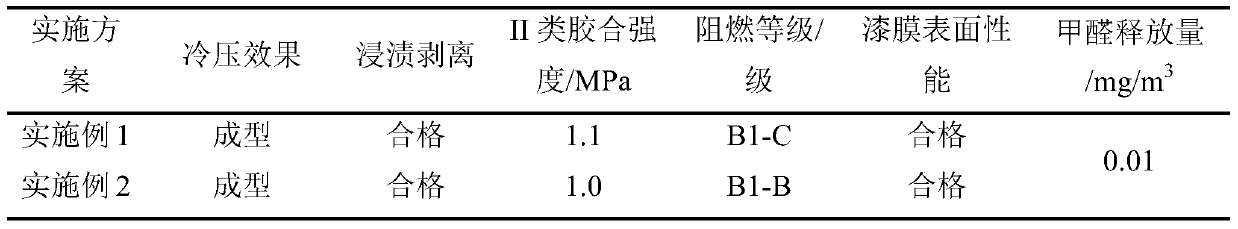

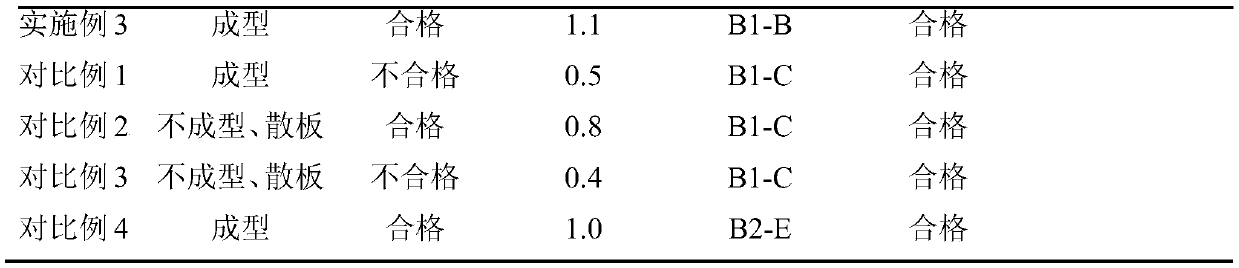

Embodiment 1

[0046] 1. Preparation of activated modified flame retardant

[0047] Add 30 parts of ammonium polyphosphate APP, 15 parts of melamine phosphate MP, 3 parts of sodium dodecylbenzenesulfonate, and 5 parts of sodium silicate in the high-speed mixer, and stir for 15 minutes, then add 65 parts of aluminum hydroxide, Stir for another 20 minutes until uniform, and the activated modified flame retardant is obtained;

[0048] 2. Preparation of modified soybean formaldehyde-free flame retardant adhesive

[0049] Add 100 parts of modified polyamide resins, 70 parts of water, 140 parts of defatted soy flour, 80 parts of activated modified flame retardants, 6 parts of water-based tackifier 880G, and 0.15 parts of polyethylene glycol in the reaction kettle successively. Stir at ~85°C for 2 hours until uniform, and the modified soybean formaldehyde-free flame-retardant rubber is prepared;

[0050] 3. Preparation of formaldehyde-free flame-retardant parquet

[0051] 1) Coat the modified so...

Embodiment 2

[0055] The production process of step 3 in embodiment 1 is unchanged, and the changes are as follows:

[0056] 1. Preparation of activated modified flame retardant

[0057] Add 35 parts of ammonium polyphosphate APP, 15 parts of melamine phosphate MP, 2.5 parts of sodium dodecylbenzenesulfonate, and 6 parts of sodium silicate in the high-speed mixer, and stir for 15 minutes, then add 75 parts of aluminum hydroxide, Stir for another 20 minutes until uniform, and the activated modified flame retardant is obtained;

[0058] 2. Preparation of modified soybean formaldehyde-free flame retardant adhesive

[0059] Add 100 parts of modified polyamide resins, 65 parts of water, 130 parts of defatted soy flour, 110 parts of activated modified flame retardants, 7 parts of water-based tackifier 880G, and 0.15 parts of polyethylene glycol in the reactor. Stir at ~85°C for 2 hours until uniform, and the modified soybean formaldehyde-free flame-retardant rubber is prepared.

Embodiment 3

[0061] Step one and two production processes in embodiment 1 are all unchanged, and change part is as follows:

[0062] 3. Preparation of formaldehyde-free flame-retardant parquet

[0063] 1) Coat the modified soybean formaldehyde-free flame-retardant glue prepared in step 2 on the surface of eucalyptus veneer with a thickness of 2.2mm, and the coating amount is 250g / m 2 , according to the crisscross formation of each layer of multi-layer plywood for solid wood composite flooring, after cold pressing and hot pressing, it is made into a flame-retardant multi-layer substrate layer. The process conditions are cold pressing time 1h, unit pressure 9kg / cm 2 , hot pressing temperature 125 ℃, (52+25) s / mm, unit pressure 9kg / cm 2 ;

[0064] 2) After the flame-retardant multi-layer substrate layer is balanced, apply the modified soybean formaldehyde-free flame-retardant adhesive prepared in step 2, the upper surface is bonded to the oak wood surface with a thickness of 1.2 mm, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com