Cutting device and bag making machine

A technology of shearing device and bag making machine, applied in bag making operation, packaging, transportation and packaging, etc., can solve the problems of long equipment size, affecting product quality, increasing labor cost, etc., to reduce equipment size and improve mold. The effect of cutting efficiency and improving die-cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

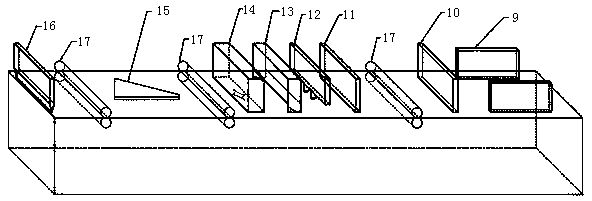

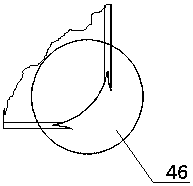

[0038] This embodiment provides a shearing device, such as Figure 4 As shown, the shearing device includes an integrated die-cutting roller 26 and a die-cutting pressure roller 33 that are all cylindrical; the integrated die-cutting roller 26 is provided with at least one cutting knife, and the shape of the cutting knife is Cut the bag shape, such as Figure 5 As shown; the cutting knife is higher than the surface of the integrated die-cutting roller 26, and the die-cutting pressure roller 26 is provided with a groove, and the part of the cutting knife higher than the surface of the integrated die-cutting roller 26 can be placed in the groove Inside, the depth of the groove is greater than or equal to 1 / 2 of the thickness of the packaging bag; the integrated die-cutting roller 26 and the die-cutting pressure roller 33 are placed in parallel, and the outer diameter of the die-cutting pressure roller 33 is greater than or equal to the outer diameter of the integrated die-cuttin...

Embodiment 2

[0047] This embodiment is different from Embodiment 1 in that the integrated die-cutting roller 26 is provided with a magnetic roller core, and the cutter is made of steel or magnetic material. Utilize the magnetism of the magnet, set the cutting knife as steel material or magnetic material, the cutting knife can be directly adsorbed and pasted on the integrated die-cutting roller 26, when replacing the cutting knife, directly attach the cutting knife on the integrated die-cutting roller 26 Just pull it out, easy to install and remove.

Embodiment 3

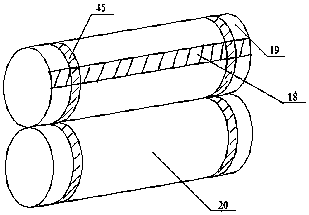

[0049] Such as image 3 As shown, this embodiment provides a bag making machine, including the shearing device described in Embodiment 1, and also includes a cylindrical heat-press sealing roller 19 and a heat-press pressure roller 20; the heat-press sealing roller Two annular electric heating ceramic blocks 45 are fixed on the 29, two cuboid middle electric heating ceramic blocks 18 are installed between the annular electric heating ceramic blocks 45, adjacent two intermediate electric heating ceramic blocks 18 and adjacent two annular electric heating ceramic blocks 45 heat press to form two packaging bags, such as Figure 6 Shown; The hot-press sealing roller 19 and the hot-press pressing roller 20 are placed in parallel, and the outer diameter of the hot-press pressing roller 20 is greater than or equal to the outer diameter of the hot-press sealing roller 19, and the hot-press sealing roller 19 and the hot-press pressing roller 20 Do opposite rotation.

[0050] The pair...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com