Gold stamping machine

A technology of a hot stamping machine and a working board, applied in the field of hot stamping machines, can solve the problems of inconvenient movement, inability to meet the use of small enterprises and shops, and large volume, and achieve the effects of simple and convenient operation, good hot pressing effect and high hot pressing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

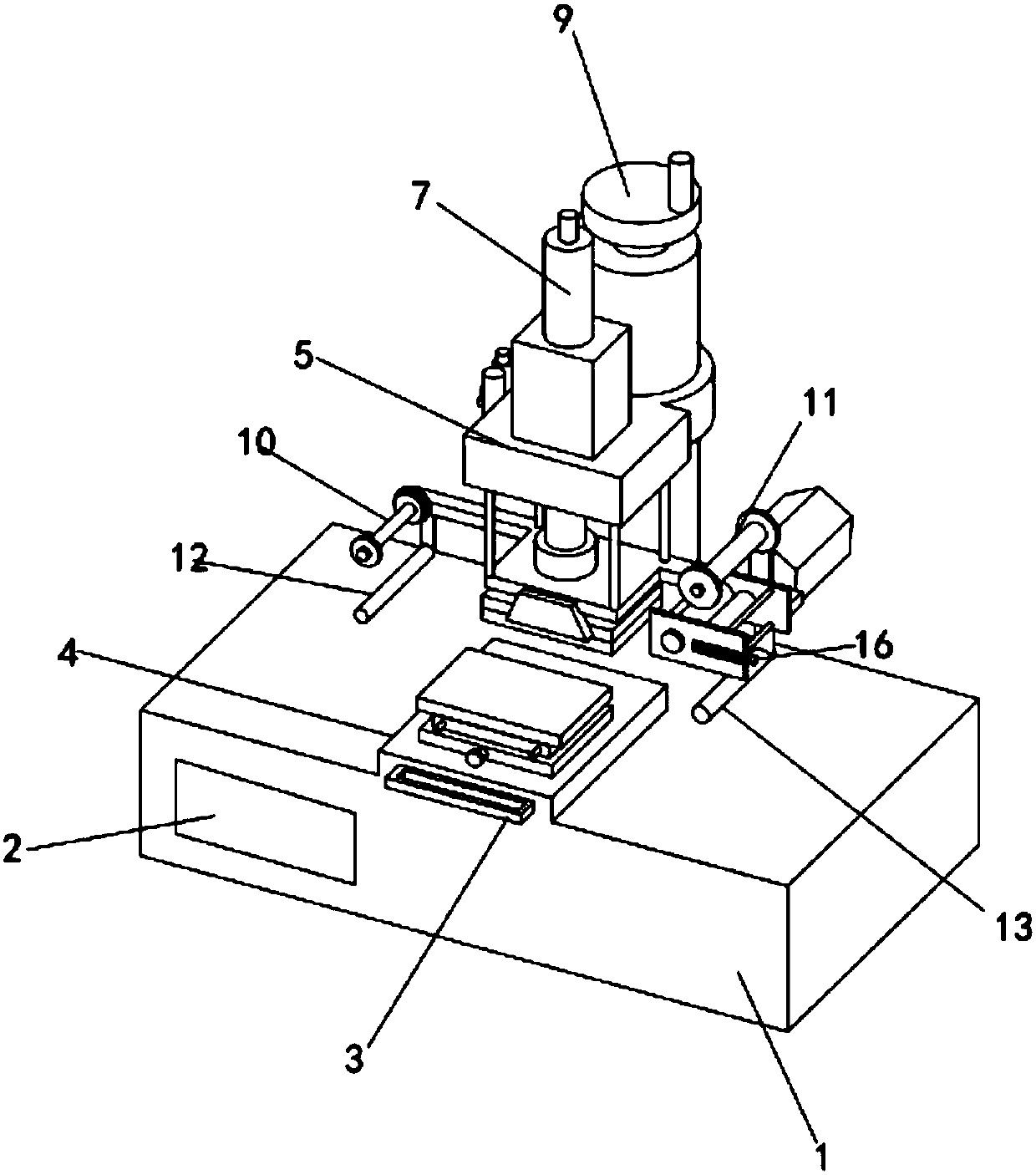

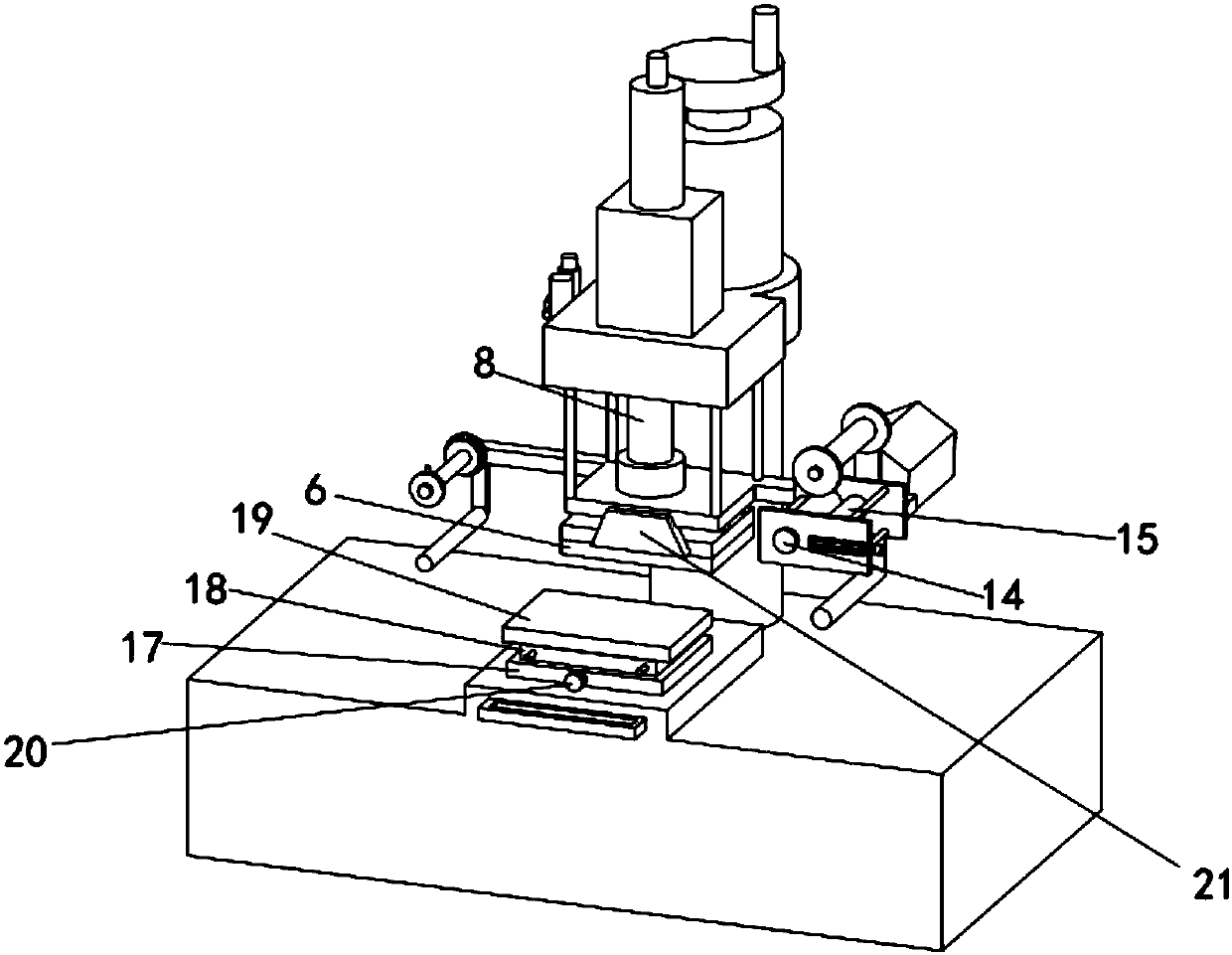

[0013] Embodiment 1: refer to Figure 1-2 , a bronzing machine, comprising a base 1, a control panel 2 arranged in front of the base 1, a pull-out workbench 3 arranged above the base 1, an adjustable working board 4 arranged above the pull-out workbench 3, and an adjustable working board 4 arranged above the adjustable working board 4 The bronzing device 5 includes a heating plate 6 and a cylinder 7. A piston rod 8 is arranged above the heating plate 6. The cylinder 7 drives and connects the piston rod 8 to push the heating plate 6 to move vertically. The lifting hand wheel 9 is connected with the cylinder 7, and the two sides of the support on the upper part of the heating plate 6 are respectively connected with the feeding reel 10 and the receiving reel 11, and the stepping motor drives the receiving reel 11 to rotate through the gear and the conveyor belt. Drive feeding reel 10 to rotate.

[0014] Further, the left bridge shaft 12 is arranged under the feeding reel 10, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com