Preparing method for dampproof mould-proof low-formaldehyde medium and high density fiberboard

A high-density fiberboard and low-formaldehyde technology, applied in fiber raw materials, fiber raw material processing, chemical instruments and methods, etc., can solve the problems of high price and high production cost, and achieve the effects of improving moisture resistance, product quality, and fiber temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

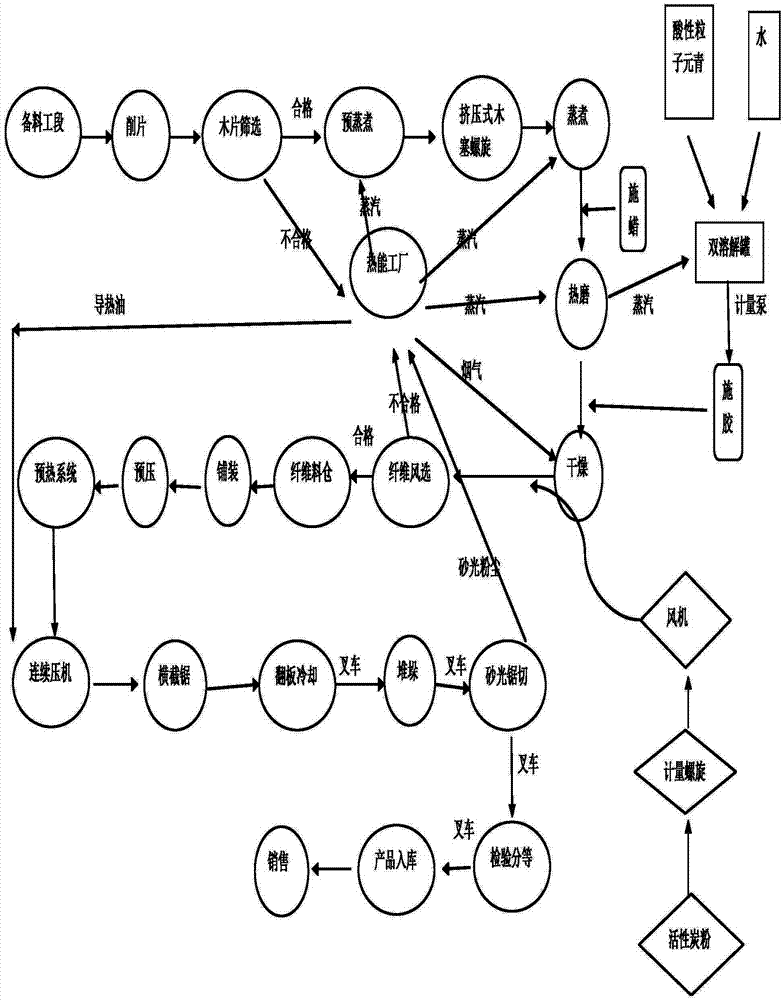

Image

Examples

specific Embodiment 1

[0029] The present invention is a moisture-proof, mildew-proof, low-formaldehyde type medium and high-density fiberboard preparation method, and the preparation method comprises the following steps:

[0030] (1) chipping step: cutting the three leftovers of branch wood forestry into evenly sized wood chips by a chipper;

[0031] (2) Screening step: remove unqualified wood chips and impurities through the wood chips of step (1) through a swing sieve and winnowing;

[0032] (3) Pre-cooking step: the wood chips in step (2) are sent into the pre-cooking bin, and then sent into the mill;

[0033] (4) Thermal grinding step: the wood chips in step (3) are decomposed into fibers through a thermal grinder to decompose the wood chips that have been cooked at a high temperature of 165-175 ° C and at a high pressure of 0.8-0.9 MPa;

[0034] (5) Drying step: the fiber in step (4) is mixed with activated carbon powder in the drying pipeline;

specific Embodiment 2

[0048] The difference with specific embodiment 1 is:

[0049] In the hot grinding process, add ingredients according to the following weight ratio: 230kg / m 3 Urea-formaldehyde resin adhesive, 8kg / m 3 Refined paraffin wax, 1.5 / m 3 The solidifying agent is an acidic particle yuanqing solution that accounts for 1% of the dry fiber. Particle Yuanqing is added to water and heated to 60 degrees in the dissolution tank. The mass ratio of acid particle Yuanqing solution to water and acid particle Yuanqing is 4:1. Grinding in the spray pipe.

[0050] In the drying process, the ingredients are added according to the following weight ratio: the 150-mesh activated carbon powder is spirally quantified and then transported to the drying pipe by the fan to fully merge with the fibers. The inlet temperature of the drying pipeline is below 175°C, the outlet temperature is 60°C, and the airflow with a wind speed of 30m / s is used for drying and mixing with activated carbon powder. After dryi...

specific Embodiment 3

[0052] The difference with specific embodiment 1,2 is:

[0053] In the hot grinding process, add ingredients according to the following weight ratio: 210kg / m 3 Urea-formaldehyde resin adhesive, 7kg / m 3 Refined paraffin wax, 1.6kg / m 3 The solidifying agent is an acidic particle Yuanqing solution that accounts for 1.1% of the dry fiber. Particle Yuanqing is added to water and heated to 55 degrees in the dissolution tank. The mass ratio of acid particle Yuanqing solution to water and acid particle Yuanqing is 4:1. Grinding in the spray pipe.

[0054] In the drying process, the ingredients are added according to the following weight ratio: the 170-mesh activated carbon powder is quantified by the spiral and then transported to the drying pipe by the fan to fully merge with the fibers. The inlet temperature of the drying pipeline is below 175°C, the outlet temperature is 50°C, and the airflow with a wind speed of 30m / s is used for drying and mixing with activated carbon powder....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com