Wood fiber thermal modified wood-plastic composite device and preparation technology of wood-plastic composite

A wood-plastic composite material and wood fiber technology, which is applied in the field of wood fiber heat-modified wood-plastic composite material equipment and wood-plastic material preparation technology, can solve problems such as cancer, cumbersome installation, and poor weather resistance, and achieve improved hot pressing Efficiency, improvement of environmental protection performance, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

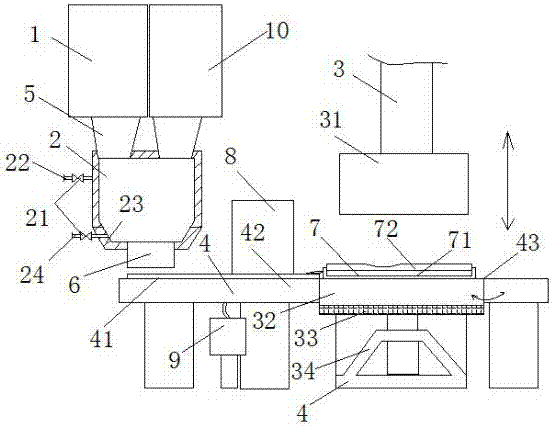

[0021] In order to deepen the understanding of the present invention, the following further describes the present invention with reference to the accompanying drawings and embodiments. The embodiments are only used to explain the present invention and do not limit the protection scope of the present invention.

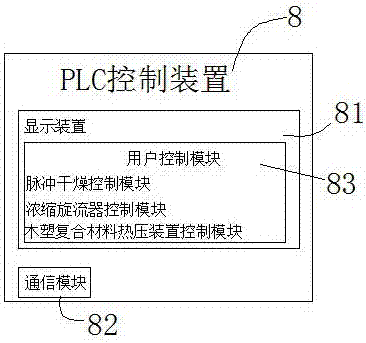

[0022] Such as figure 1 As shown, the wood fiber thermally modified wood-plastic composite material equipment includes a pulse drying cylinder 1, a concentration cyclone 2, a wood-plastic composite material hot pressing device 3, and a hot pressing platform 4, which are sequentially connected. The connected mold loading station 41, the conveying mold device 42 and the mold hot pressing station 43; among them:

[0023] The pulse drying cylinder 1 is connected to the top position of the concentration cyclone 2 through a transparent feeding tube 5, and the top is also connected with a PVC raw material blanking device 10; the concentration cyclone 2, the center height position i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com