Bamboo plywood for structure

A technology for gluing bamboo boards and structures, which is used in the joining of wooden veneers, wood processing appliances, layered products, etc., to achieve the effect of small thickness tolerance between boards, uniform thickness, and simplified connection design and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

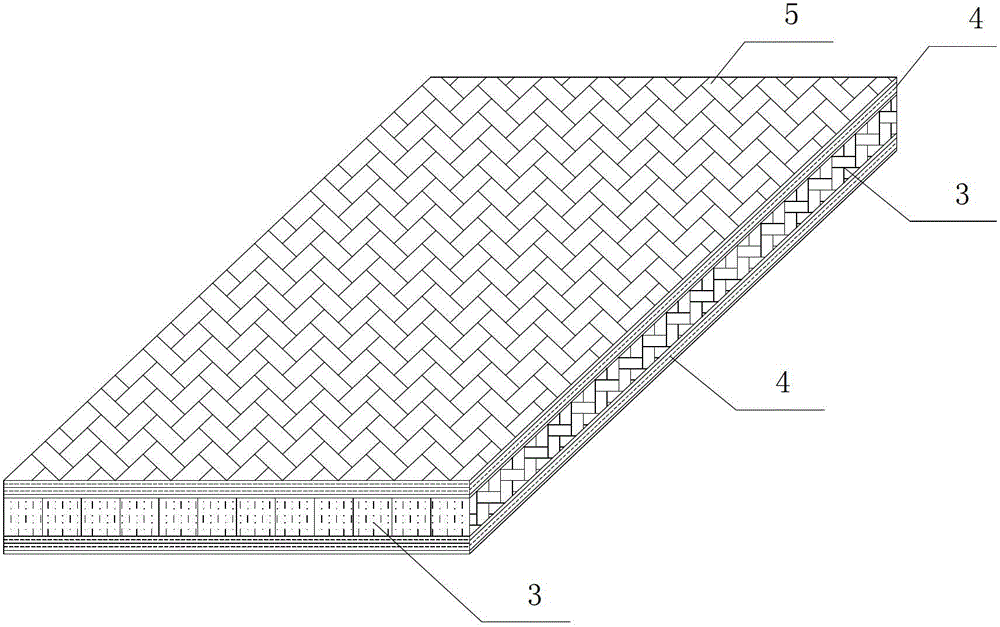

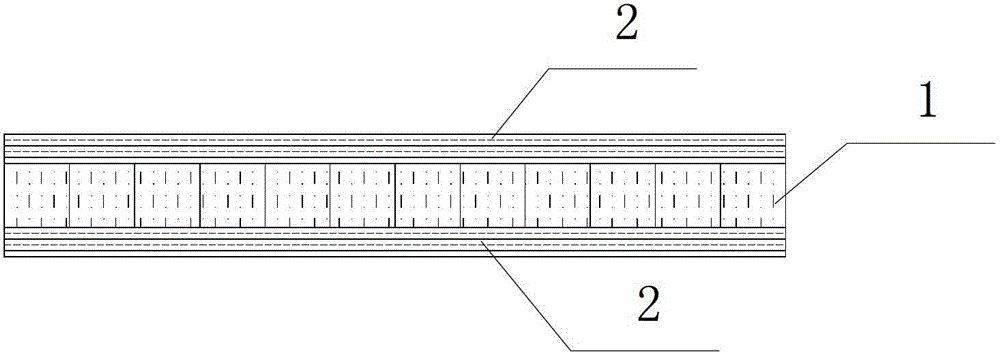

[0021] Embodiment 1: as figure 1 and figure 2 As shown, a kind of glued bamboo board for structure of the present invention, it comprises core board layer (1) and the hot-pressed layer (2) that is arranged on the both sides of core board layer (1), and core board layer (1) is by thickness 25~ The 30mm structure is made of slats (3) cut out of glued bamboo board GluBam (6), which are made by lateral cold pressing and sanding to determine the thickness. After forming, all slats (3) in the core layer (1) The pressing molding surface of itself is perpendicular to the pressing molding surface of the hot pressing layer (2). The hot-pressed layer (2) is composed of several layers of bamboo curtains (4) and a layer of mats (5). The bamboo curtain (4) is laid by stacking vertical bamboo curtains and horizontal bamboo curtains. The mechanical performance requirements of the board are determined, and the mat (5) can be an ordinary bamboo plywood mat, or can be set as other veneer mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com