Composite board pressing processing equipment

A technology for processing equipment and composite boards, applied in lamination, lamination devices, lamination auxiliary operations, etc., can solve problems such as inconvenient operation, increased labor intensity of staff, and reduced quality of composite boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

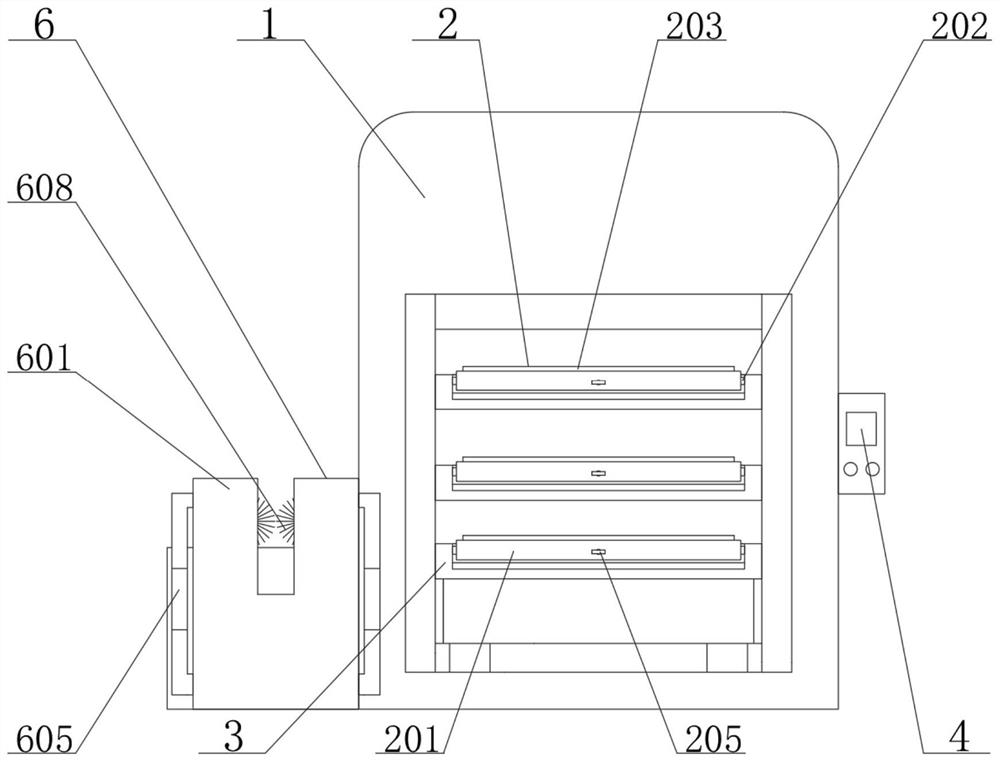

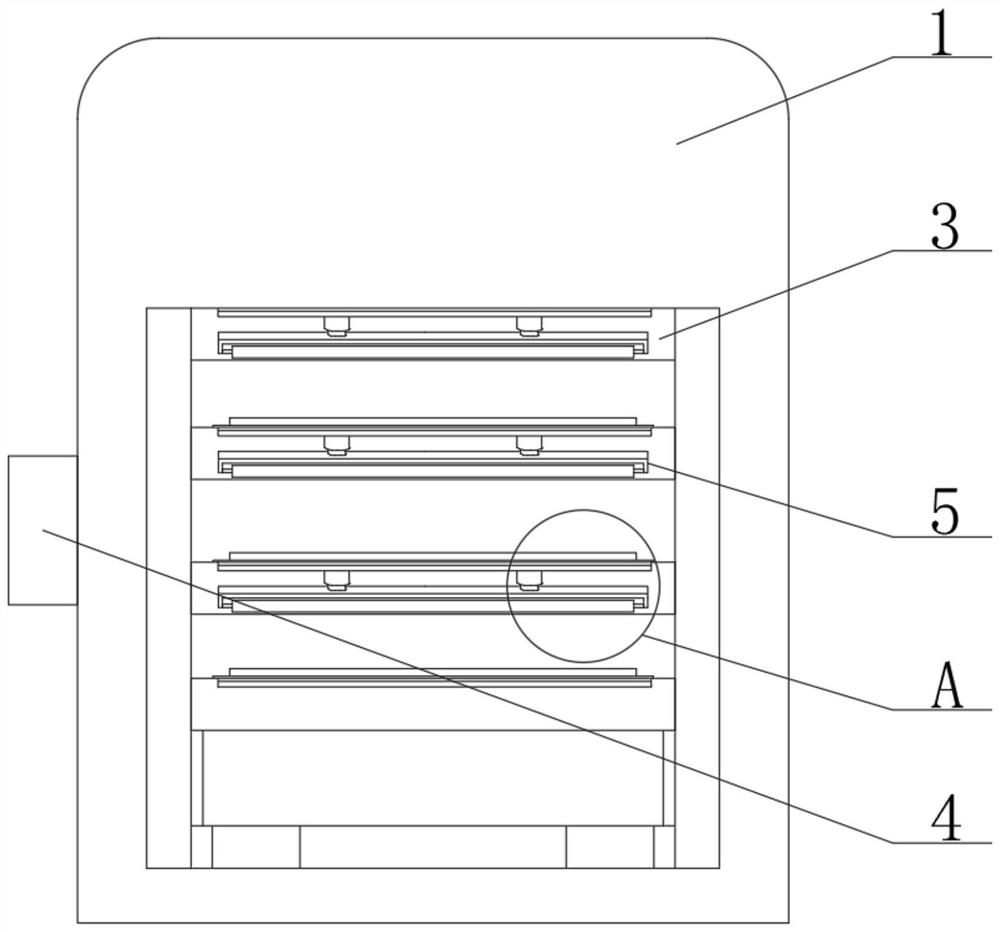

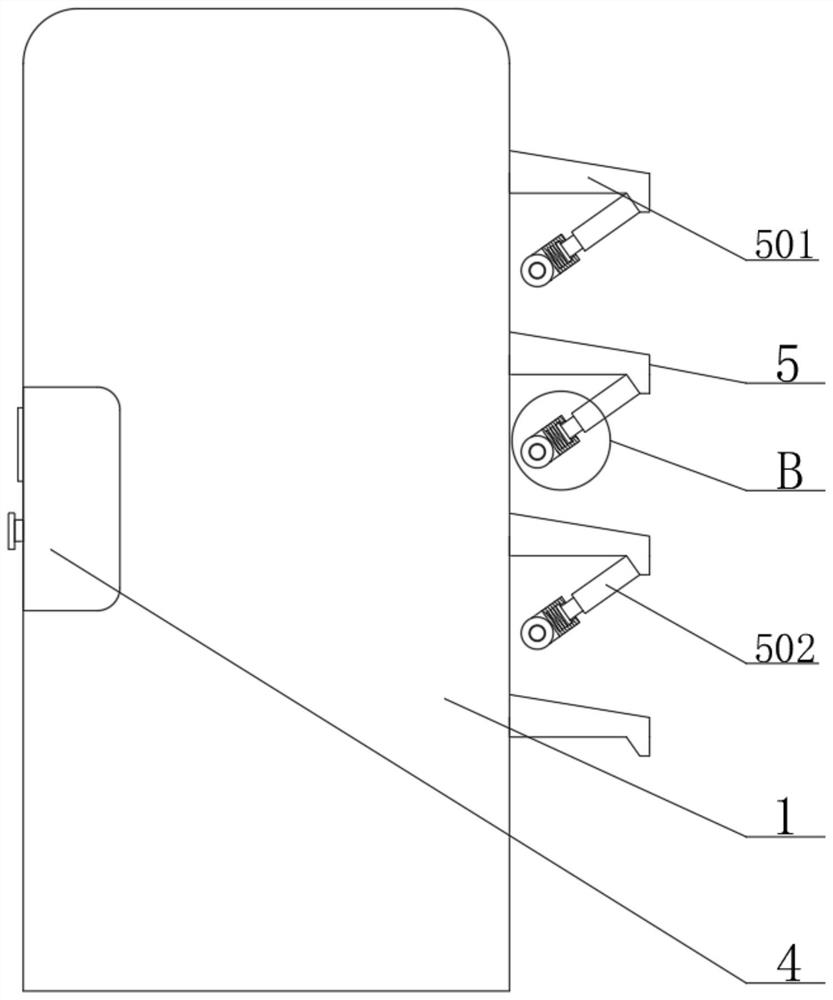

[0027] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 , the present invention provides a technical solution:

[0028] A composite plate pressing processing equipment, comprising a hot press 1, a support device 2, a blanking device 5 and a cleaning device 6, the inner side of the hot press 1 is fixedly connected with a hot pressing plate 3, and the inner side of the hot pressing plate 3 is provided with a supporting device 2 , the support device 2 includes a support plate 201, a rotating shaft 202, a limit plate 203, a first spring 204 and a handle 205, and the inner side of the three hot pressing plates 3 at the bottom is slidably connected with the support plate 201, and the inner rear end of the support plate 201 rotates The rotating shaft 202 is connected, and the rotating shaft 202 is slidably connected with the three hot pressing plates 3 located at the bottom, and the inside front ends of the three hot pressing plates 3 at the...

Embodiment 2

[0031] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 , the present invention provides a technical solution:

[0032] A composite plate pressing processing equipment, comprising a hot press 1, a support device 2, a blanking device 5 and a cleaning device 6, the inner side of the hot press 1 is fixedly connected with a hot pressing plate 3, and the inner side of the hot pressing plate 3 is provided with a supporting device 2 , the support device 2 includes a support plate 201, a rotating shaft 202, a limit plate 203, a first spring 204 and a handle 205, and the inner side of the three hot pressing plates 3 at the bottom is slidably connected with the support plate 201, and the inner rear end of the support plate 201 rotates The rotating shaft 202 is connected, and the rotating shaft 202 is slidably connected with the three hot pressing plates 3 located at the bottom, and the inside front ends of the three hot pressing plates 3 at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com