Continuous and stable hot-pressing equipment for furniture boards

A technology for hot-pressing equipment and furniture, applied in the direction of veneer presses, plywood presses, manufacturing tools, etc., can solve the problems of overheating, loss, and board breakage of cylinders, and achieve stable and safe hot-pressing opportunities, simple and reasonable structure, High heat-pressing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

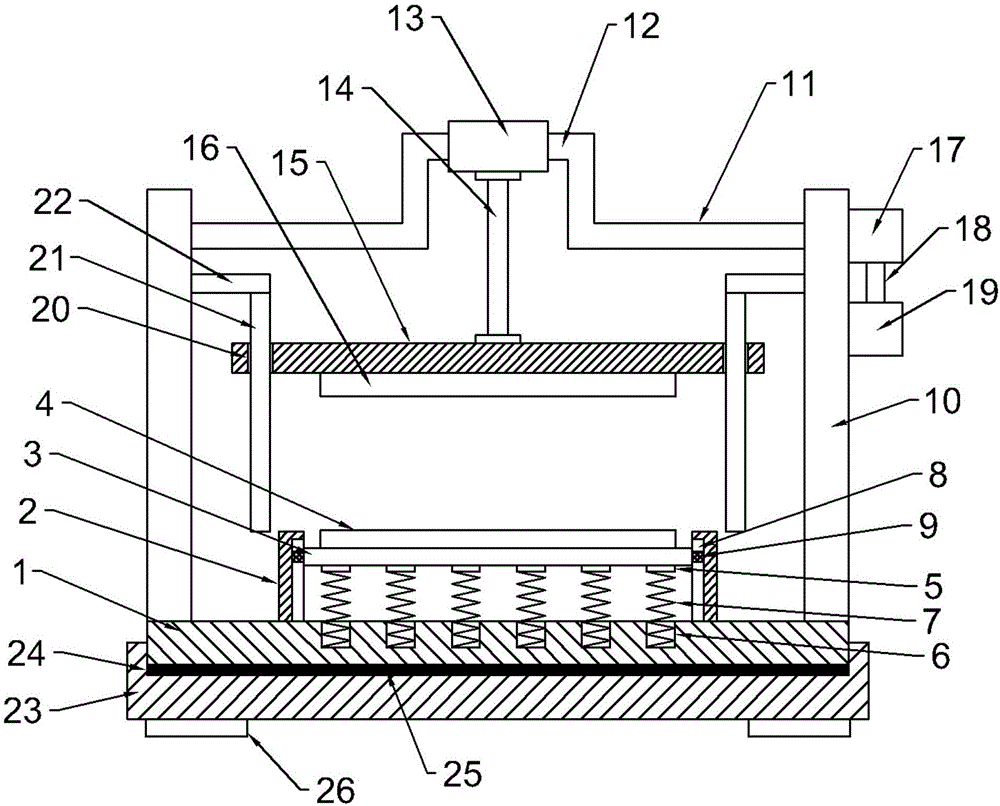

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

[0016] see figure 1 , a continuous and stable furniture board hot-pressing equipment, including a base plate 1, the upper end of the base plate 1 is symmetrically installed with a limit plate 2 parallel to each other along the center, and the limit plate 2 is perpendicular to the base plate 1, and the two limit plates A support plate 3 is provided between the plates 2, a workbench 4 is provided on the upper surface of the support plate 3, a number of connectors 5 are provided on the lower surface of the support plate 3, and a number of concave holes corresponding to the connecting rods 5 are provided on the upper end of the bottom plate 1. Groove 6, buffer spring 7 is arranged in the groove 6, and the upper end of buffer spring 7 is fixedly installed on the connector 5, and when the plank is prevented on the workbench 4, the workbench 4 can play a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com