Hot pressing mechanism convenient to clean

A hot pressing mechanism and cleaning technology, which is applied to veneer presses, plywood presses, cleaning methods and appliances, etc., can solve problems such as difficult cleaning, achieve the effects of improving the effect, ensuring cleanliness, and ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

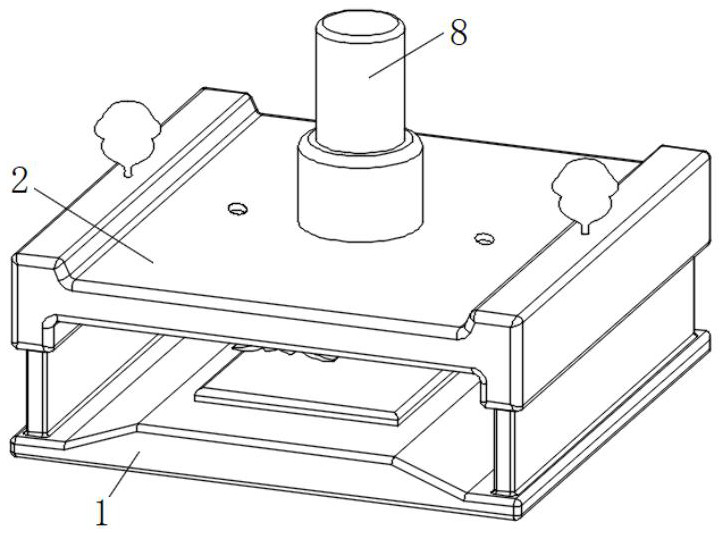

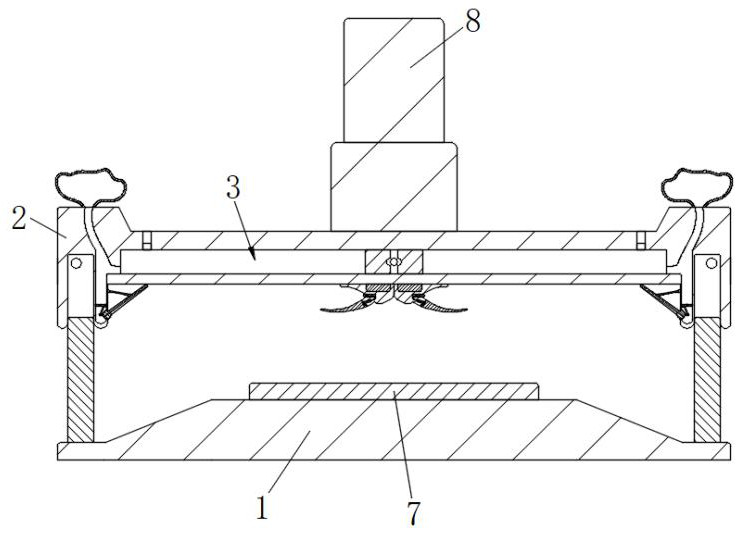

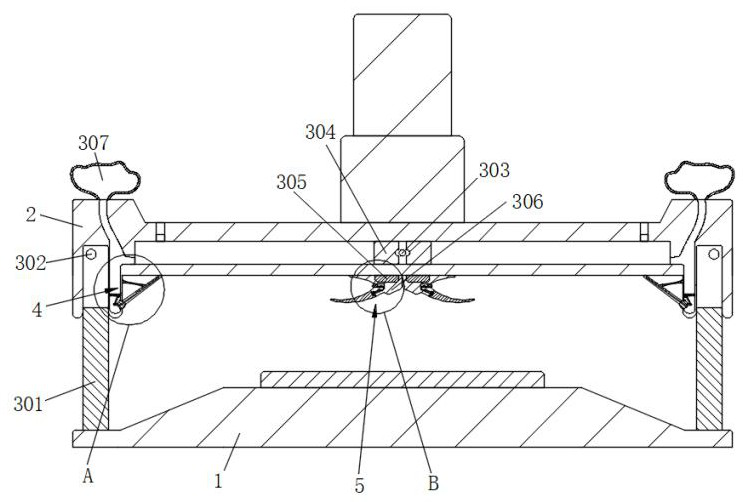

[0024] see Figure 1-5 , the present invention provides a technical solution: a hot-pressing mechanism that is easy to clean, including a pressing plate 2, an air inlet groove is provided inside the pressing plate 2, a check valve is arranged inside the air inlet groove, and the air inlet end of the check valve and the pressing plate 2 is externally connected, the gas outlet of the one-way valve is connected to the inside of the chute, the top of the pressure plate 2 is fixedly connected with the electric telescopic rod 8, the bottom of the pressure plate 2 is provided with the bottom plate 1, the top of the bottom plate 1 is provided with a plate 7, and the inside of the pressure plate 2 is provided with glue Automatic cleaning and scraping mechanism 3;

[0025] The automatic cleaning and scraping mechanism 3 of gluing comprises stop bar 301, air outlet 302, air inlet 303, magnet slide block A304, and the quantity of magnet slide block A304 is two, and the side that two magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com