Convenient-to-position high-applicability glue pressing device for furniture processing

An applicability and glue-pressing technology, which is applied in the direction of adhesive application device, wood processing equipment, glue gun, etc., can solve the problems of adjusting the size of the glue-pressing device, being crushed, and troublesome boards, etc., so as to reduce labor force, avoid collision, prevent The effect of sheet peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

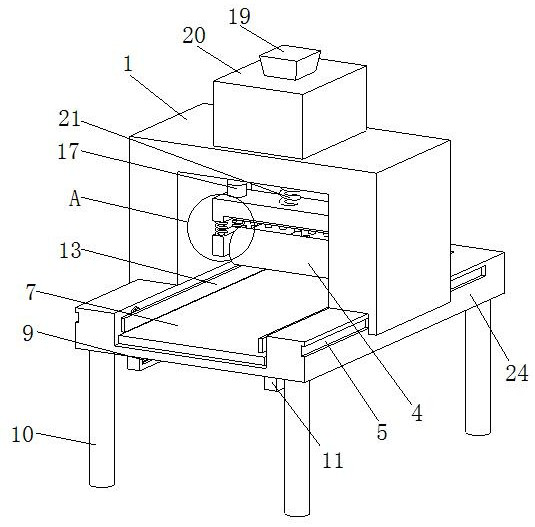

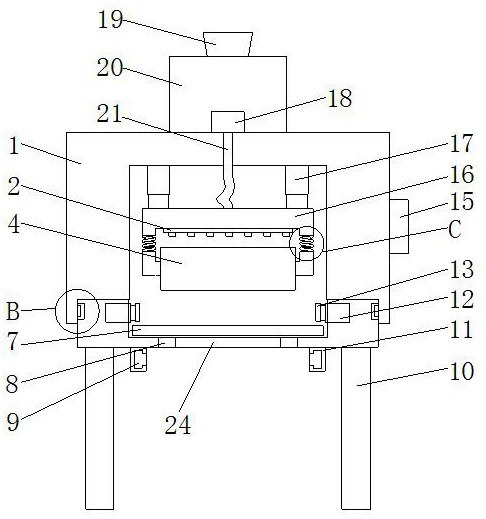

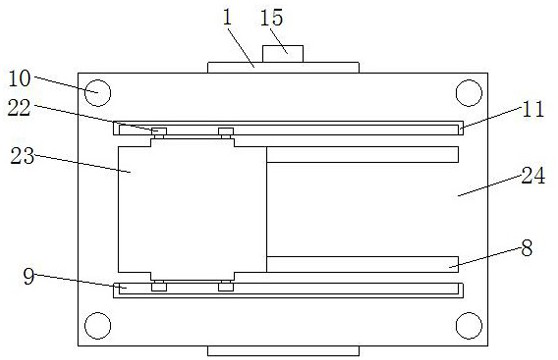

[0027] see Figure 1-7 , the present invention provides a technical solution: including a casing 1 and a table frame 24, two electric telescopic rods 17 are fixedly installed inside the casing 1, and an installation frame 16 is fixedly installed on the end of the electric telescopic rods 17 away from the casing 1, The top and the bottom of the mounting frame 16 inner cavity are all fixedly installed with a limit column 3, the outer side of the limit column 3 is fixedly equipped with a telescopic spring 14, the inner side of the mounting frame 16 is fixedly equipped with a rubberized roller brush 4, and the opposite side of the casing 1 The slide block 6 is fixedly installed, and the inside of the table frame 24 is provided with two track grooves 8, and the inner side of the table frame 24 is movably installed with a working plate 7, and the inside of the opposite side of the table frame 24 is fixedly installed with a miniature electric telescopic rod 12, and the miniature An e...

Embodiment 2

[0030] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the top of the casing 1 is fixedly installed with a glue box 20, the top of the glue box 20 is connected with a glue inlet pipe 19, and the inner cavity of the glue box 20 is A glue pump 18 is fixedly installed at the bottom of the casing 1, a control box 15 is fixedly installed on one side of the casing 1, and a hose 21 is fixedly installed on the glue pump end of the glue pump 18, and the end of the hose 21 away from the glue pump 18 runs through the machine. The shell 1 extends to the outside of the installation frame 16, and the top of the inside of the installation frame 16 is fixedly installed with a plurality of glue spray heads 2.

[0031] In this embodiment, the role of the pressure glue box 20 needs to be used for the pressure glue. The glue inlet pipe 19 connected to the top of the glue box 20 is used to add the glue glue inside the glue box 20. Sinc...

Embodiment 3

[0033] Such as Figure 1-7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a kind of technical scheme: the interior of both sides of the table frame 24 is provided with chute 5, and the specification of chute 5 is the same as that of slider 6. Adapted, and the slider 6 is slidably installed in the inside of the chute 5, and the bottom of the table frame 24 is fixedly equipped with four support legs 10, and the four support legs 10 are evenly distributed on the bottom of the table frame 24 in a rectangular shape.

[0034] In this embodiment, the gluing device is assembled by slidingly installing the slider 6 inside the chute 5. If the gluing device needs to be transported or fully cleaned, the fixing device is removed, and the casing 1 is slid on both sides. The block 6 slides out from the chute 5 on both sides of the table frame 24. On the one hand, the glue pressing device can be used for long-distance and short-distance transportation....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com