Gluing and sealing equipment for multi-layer splicing position of plywood

A technology of sealing equipment and plywood, which is applied in metal processing equipment, grinding/polishing equipment, glue guns, etc., can solve the problems of poor glue binding effect, lack of feeding device, and inability to realize automation of the device, so as to improve the gluing effect and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

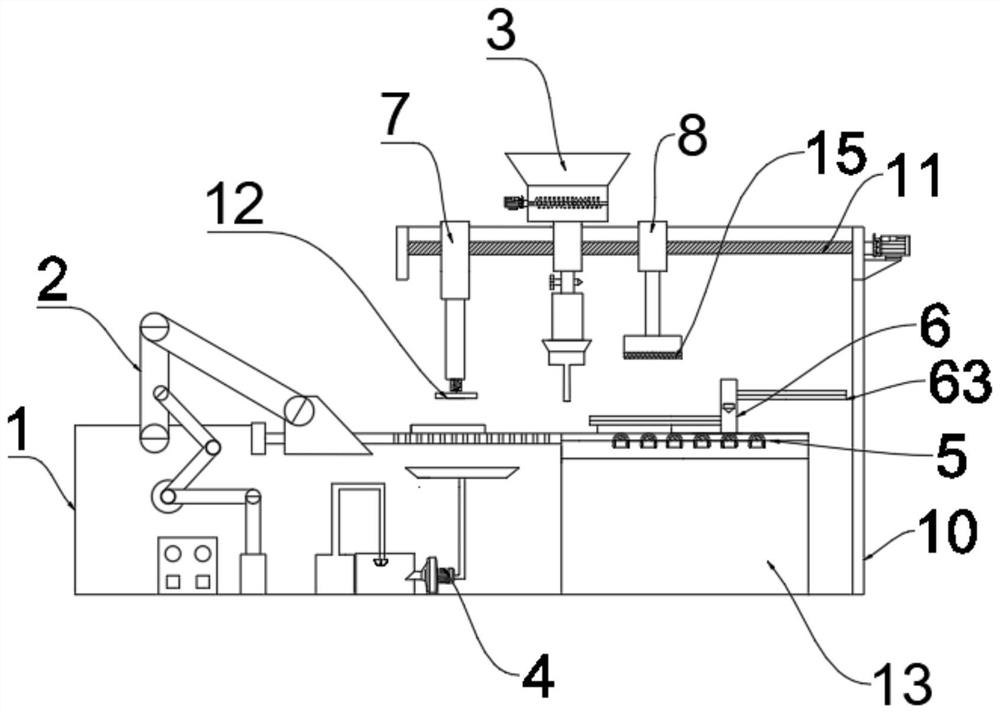

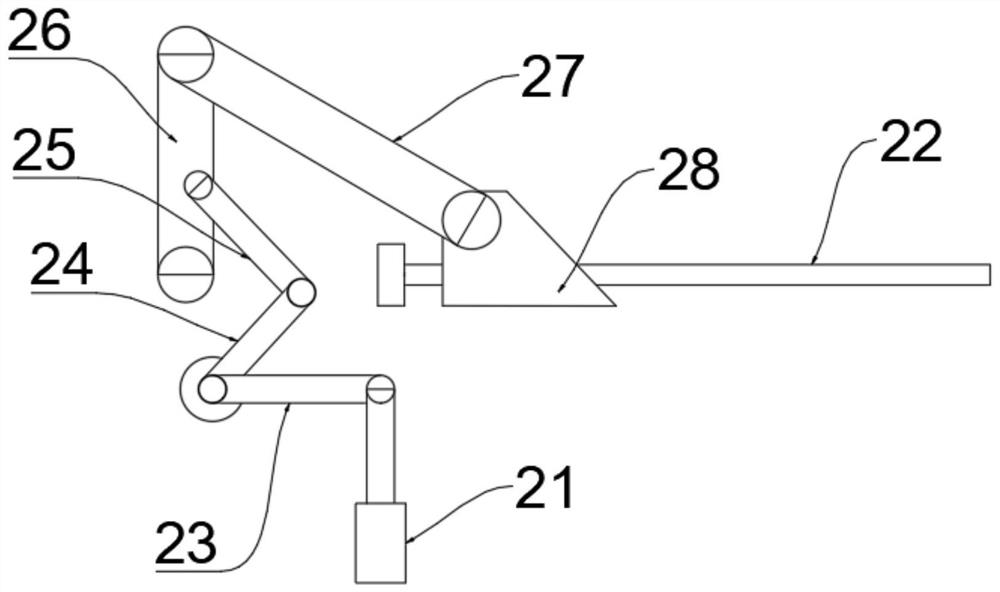

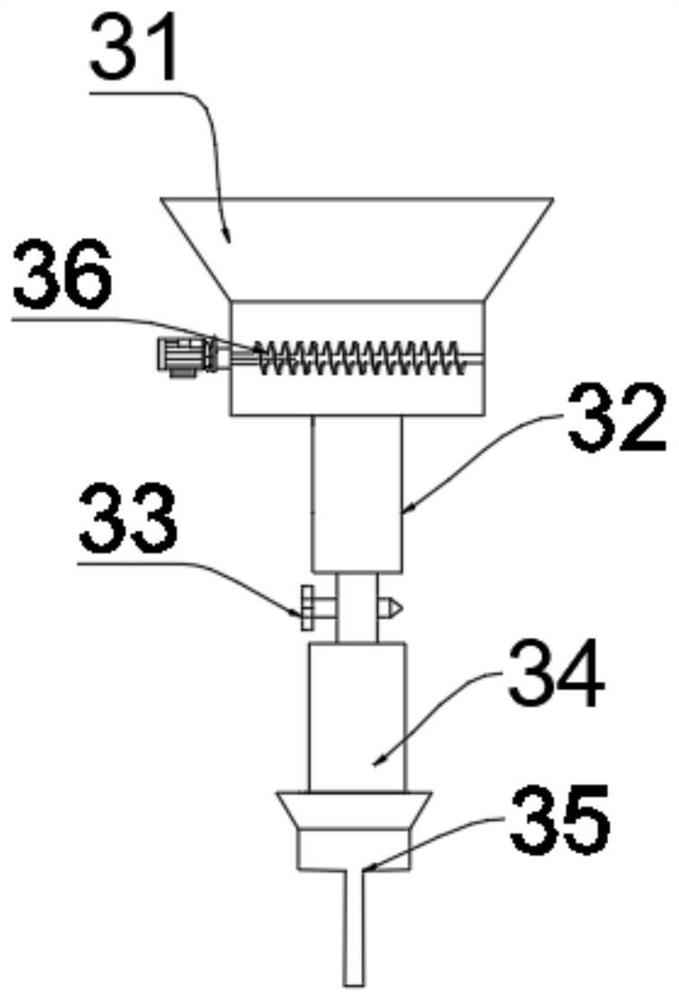

[0030] refer to Figure 1-6, a kind of glue coating and sealing equipment for multi-layer plywood joints, comprising a base 1, a feeding device 2 and a workbench 13 arranged on the side of the base 1, the side of the workbench 13 away from the base 1 is provided with a column 10, and the side of the column 10 is connected Screw rod 11 is arranged, and screw rod 11 is connected with grinding device 7, glue spraying device 3 and compacting device 8 by thread, and glue spraying device 3 is arranged between grinding device 7 and compacting device 8, and feeding device 2 comprises telescopic rod 21, Rotating rod 23 and the second rotating rod 24, and telescoping rod 21 is connected with rotating rod 23 rotations, and rotating rod 23 is fixedly connected with the second rotating rod 24, and the junction of second rotating rod 24 and rotating rod 23 is connected with rotation Seat, the rotating seat is fixedly connected with the side wall of the base 1, the end of the second rotating...

Embodiment 2

[0038] refer to Figure 7 , a kind of glue sealing equipment for multi-layer splicing of plywood. Compared with Embodiment 1, this embodiment has a grinding disc 12 connected to the bottom of the grinding device 7, and several thorns 14 are arranged inside the grinding disc 12, and the compacting device The bottom of 8 is connected with compacting plate, and the bottom of compacting plate is provided with shock absorbing sleeve 15.

[0039] Working principle: when in use, the dust and stains on the surface of the plywood can be removed in time by setting the grinding device 7, which is conducive to improving the quality of the plywood during gluing, and the grinding effect of the lifting device is facilitated by setting the thorn 14 at the bottom of the grinding disc 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com