Hardware accessory burr removal device

A technology of burr removal and accessories, which is applied in the direction of grinding workpiece supports, metal processing equipment, machine tools suitable for grinding workpiece edges, etc. , Improve the practicability and the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

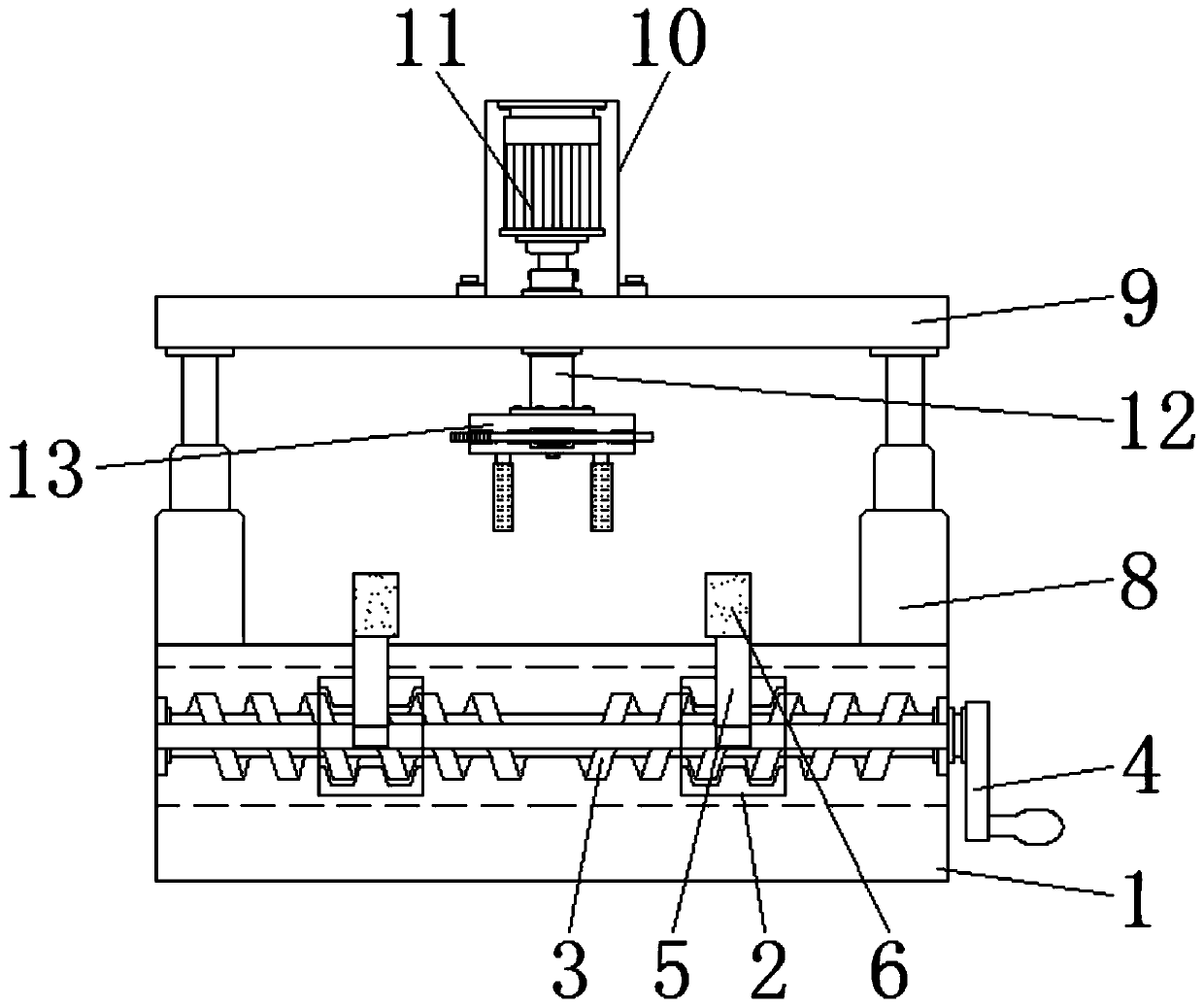

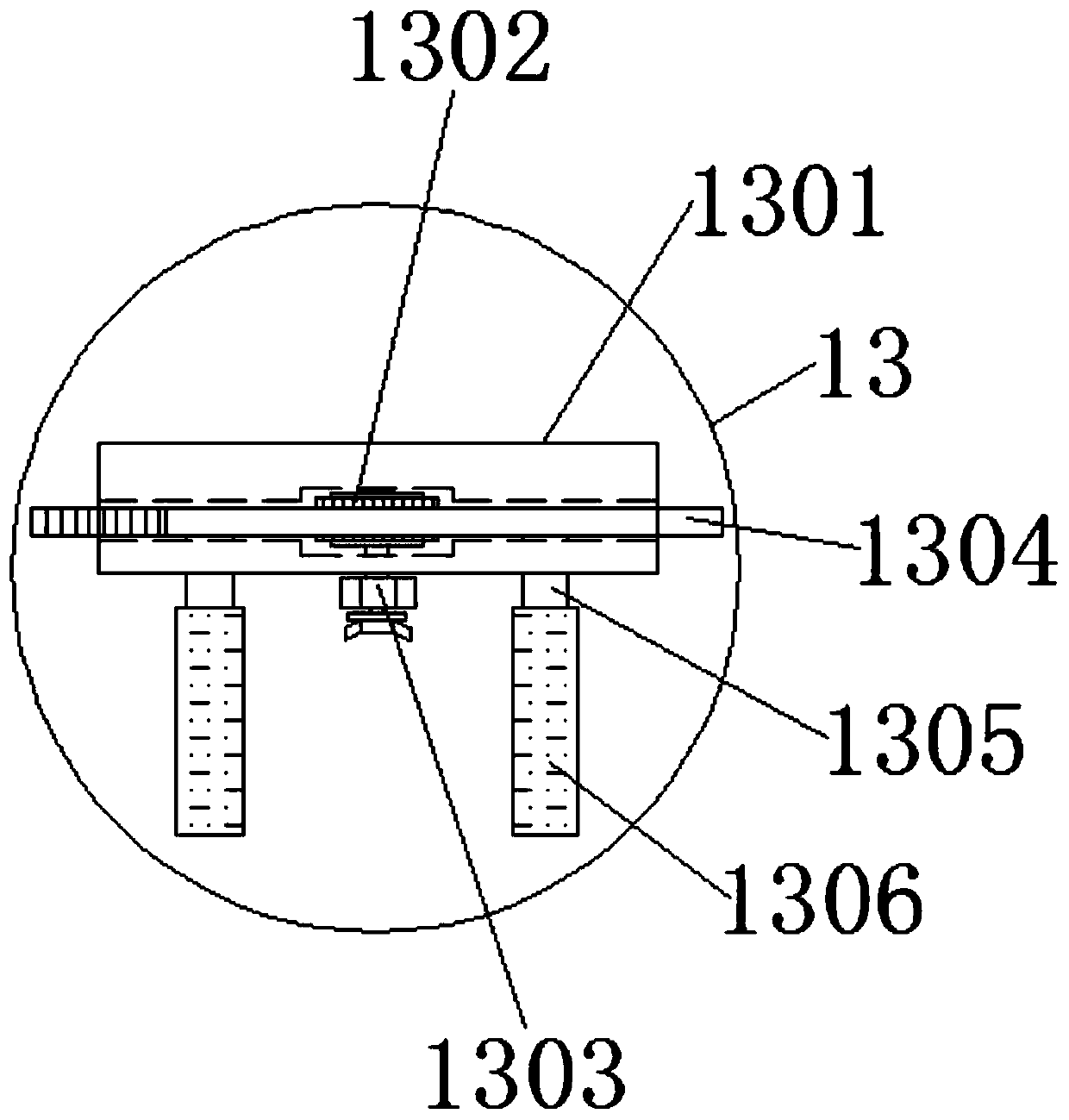

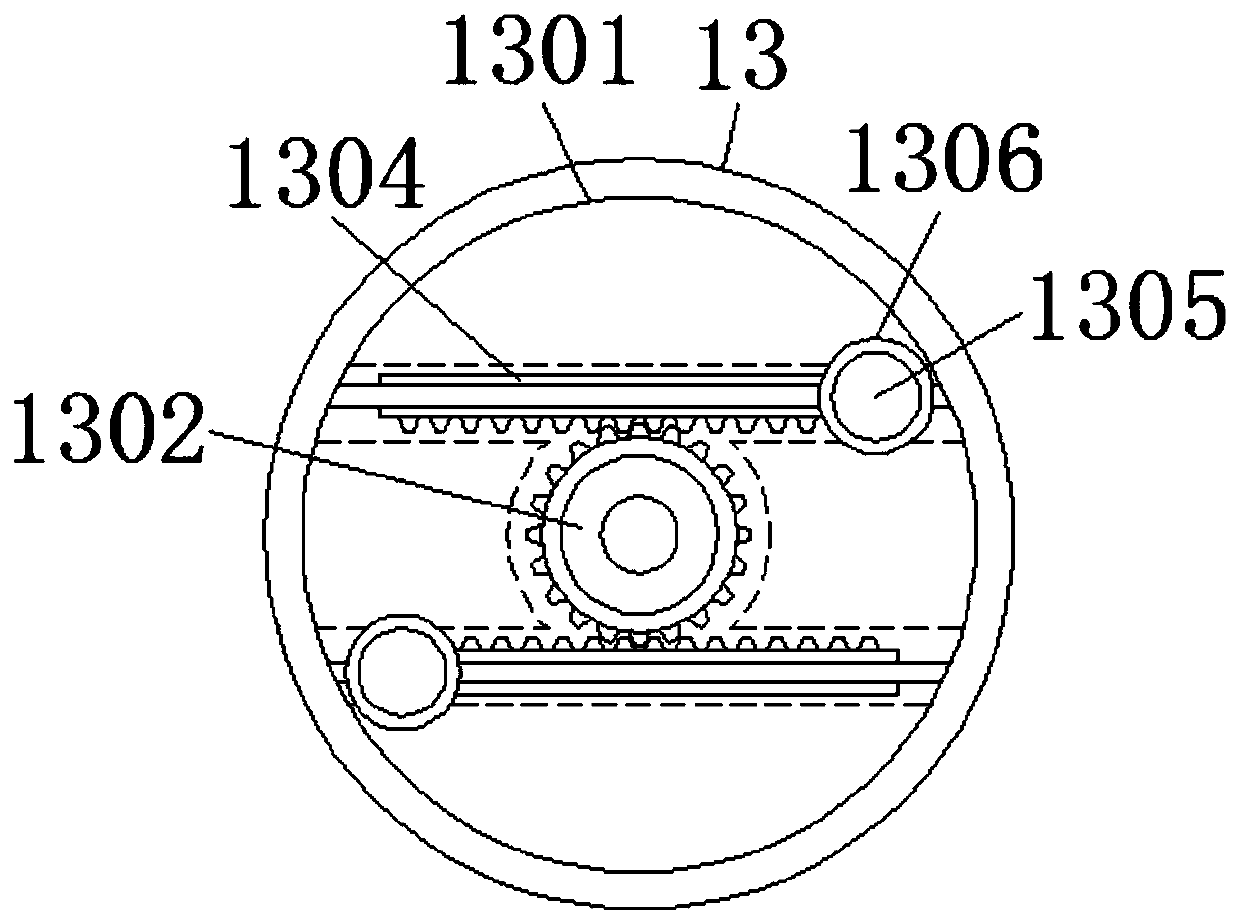

[0020] Such as Figure 1-Figure 5 As shown, a device for removing burrs from hardware accessories includes a base 1, a first slider 2, a threaded rod 3, a hand crank 4, a bracket 5, a movable block 6, an anti-skid pad 7, an electric telescopic rod 8, a movable plate 9, The motor 10, the fixed box 11, the rotating shaft 12 and the grinding device 13, the middle part of the inner side of the base 1 is slidably connected with the first slider 2, and the inner side of the first slider 2 is connected with a threaded rod 3, and the threaded rod 3 rotates with the base 1 connected, and the right end of the threaded rod 3 is fixedly connected with a hand crank 4, the front and rear sides of the first slider 2 are welded with a bracket 5, and the upper end of the bracket 5 is welded with a movable block 6, and the middle part of the movable block 6 is fixed Be connected with anti-slip mat 7, the left and right ends of base 1 upper surface all are fixedly connected with electric telesco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com