Glue smearing device for interval type wood boards

A technology for applying glue and wood boards, which is applied in the direction of adhesive application devices, glue containers, glue guns, etc., can solve the problems of uneven glue application, inability to clean the board surface, and large manpower, so as to save manpower, improve work quality, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

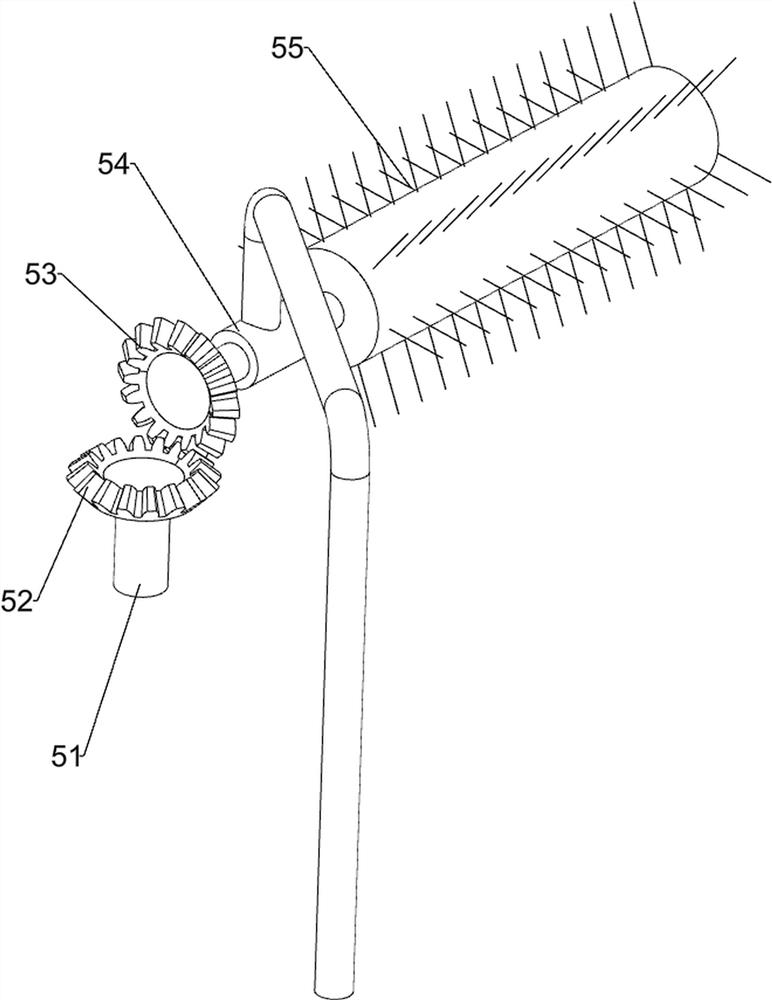

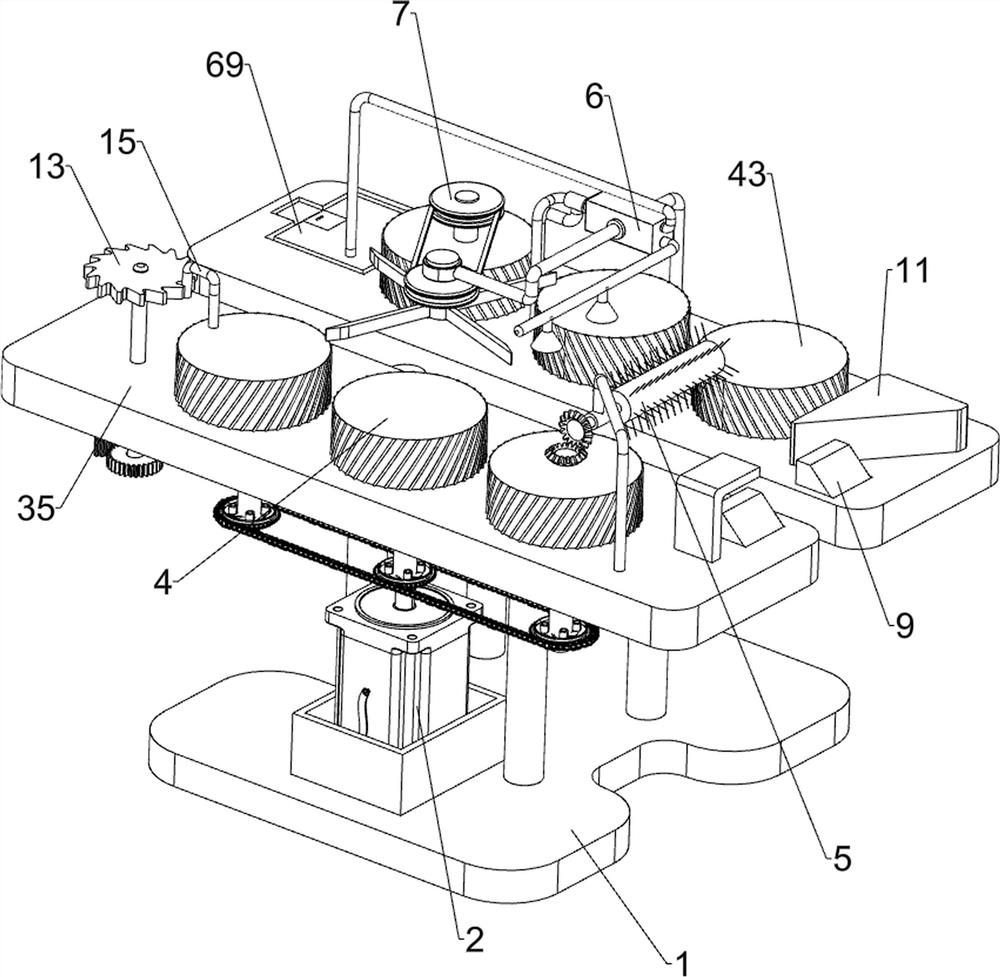

[0027] A kind of spaced board glue coating device, such as Figure 1-9 As shown, it includes a bracket 1, a servo motor 2, a moving device 3, a conveying device 4, a cleaning device 5, a glue spraying device 6 and a smoothing device 7. The bracket 1 is fixed with a servo motor 2 by bolts, and the bracket 1 is provided with There is a mobile device 3 that moves by sliding. The mobile device 3 is provided with a conveying device 4 that transmits by rotating. The mobile device 3 is provided with a cleaning device 5 that cleans by rotating. A glue spraying device for applying glue by sliding is provided, and the glue spraying device 6 is provided with a smoothing device 7 for smoothing by rotating.

[0028] When using the device, the staff starts the servo motor 2, and then places the wooden board to be coated with glue on the moving device 3. After putting it in place, the servo motor 2 rotates and drives the wooden board to move to the left through the conveying device 4, and th...

Embodiment 2

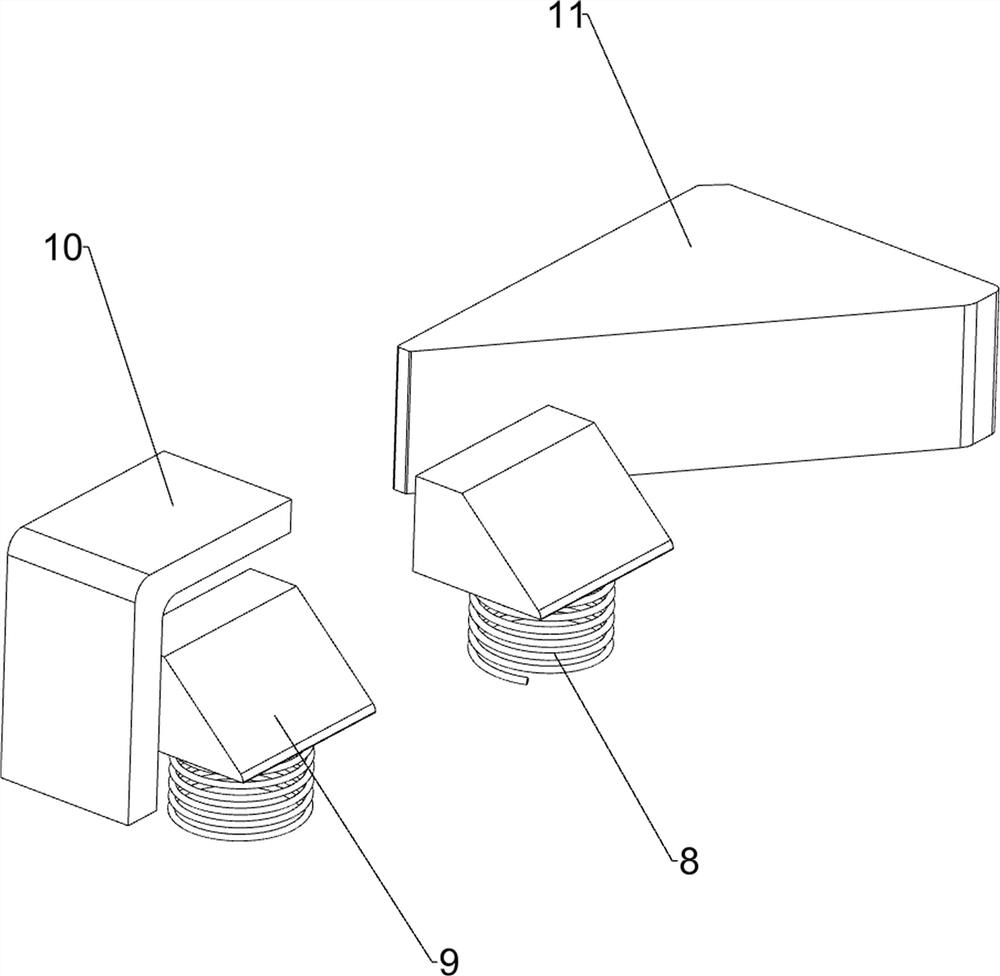

[0040] On the basis of Example 1, such as figure 1 and Figure 8 As shown, it also includes a third spring 8, a first oblique block 9, a T-shaped limit block 10 and a second oblique block 11, and the right part of the support plate 35 is slidingly provided with the first oblique block 9. A third spring 8 is connected between an oblique block 9 and the support plate 35, and the right part of the front support plate 35 is fixedly connected with a T-shaped stop block 10 by bolts, and the right part of the rear support plate 35 is provided with a second oblique spring 8. Block 11.

[0041] When smearing glue on the plank, the worker puts the plank between the T-shaped limit block 10 and the second oblique block 11, then pushes the plank to the left, and the plank moves to the left to push the first oblique block 9 on the support plate 35 Sliding up and down, the third spring 8 is compressed, and then the wooden board is sent to the left to apply glue. The shape block 9 slides u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com