Plywood manufacturing equipment based on dry heat method

A technology for manufacturing equipment and plywood, applied in the direction of manufacturing tools, wooden veneer joints, glue guns, etc., can solve the problems of plywood manufacturing efficiency, cumbersome operation steps, etc., to achieve manpower saving, high degree of intelligence, good adhesion combined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

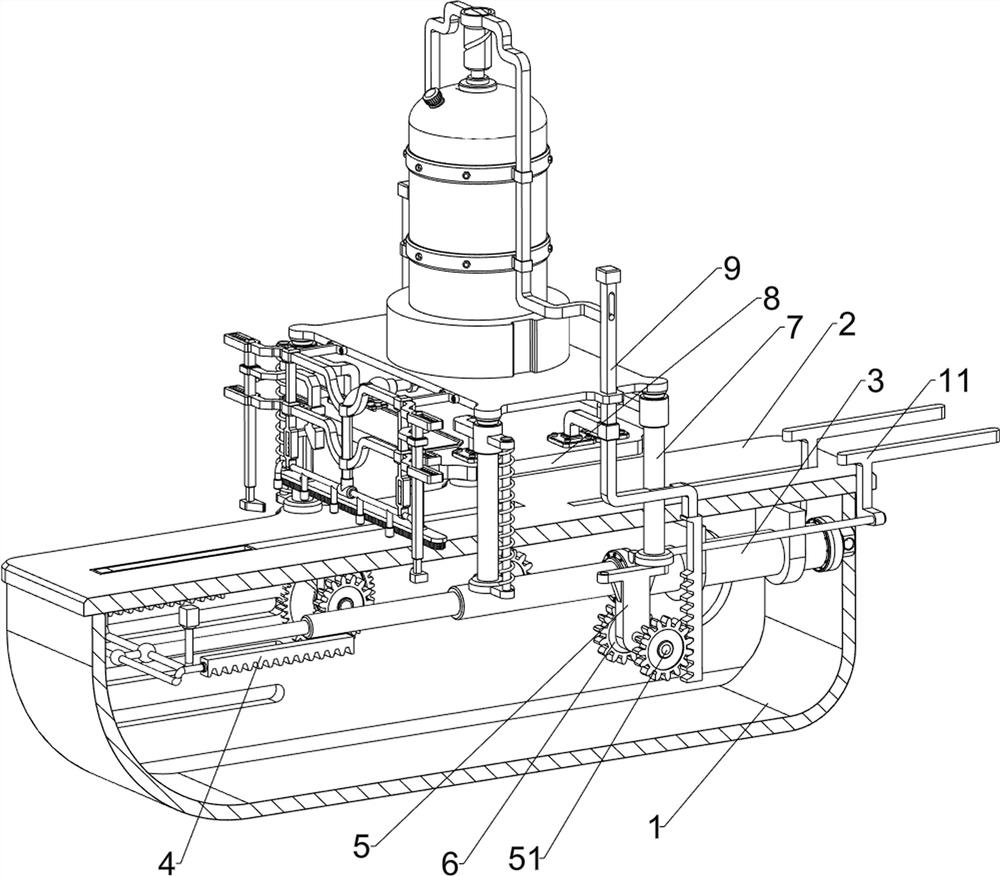

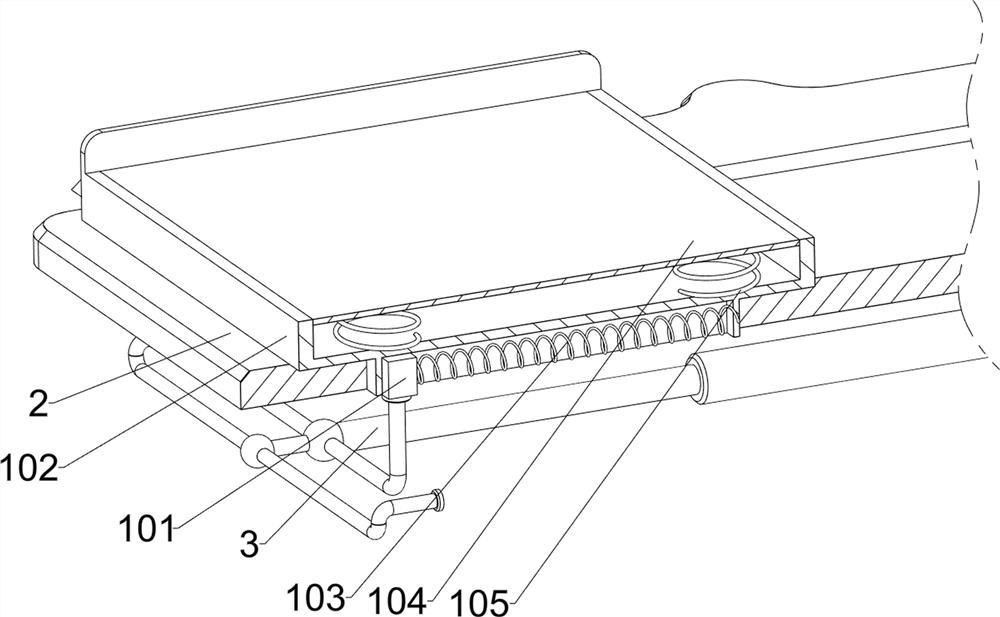

[0030] A kind of plywood manufacturing equipment based on dry heat method, refer to figure 1 with figure 2As shown, it includes a bottom plate 1, a first mounting plate 2, a multi-stage hydraulic cylinder 3, a first rack 4, a first bearing seat 5, a first rotating rod 51, a first gear 6, a mounting column 7, a pressure plate 8, The second rack 9, the feeding mechanism 10, the feeding mechanism 11 and the gluing mechanism 12, the top of the bottom plate 1 is welded with the first mounting plate 2, and the right side of the bottom of the first mounting plate 2 is provided with a multi-stage hydraulic cylinder 3. The left side of the telescopic shaft on the hydraulic cylinder 3 is symmetrically provided with a first rack 4, and the right side of the bottom of the first mounting plate 2 is symmetrically connected with a first bearing seat 5 through bolts, and the lower side of the first bearing seat 5 is provided with The first rotating rod 51, the first rotating rod 51 is conne...

Embodiment 2

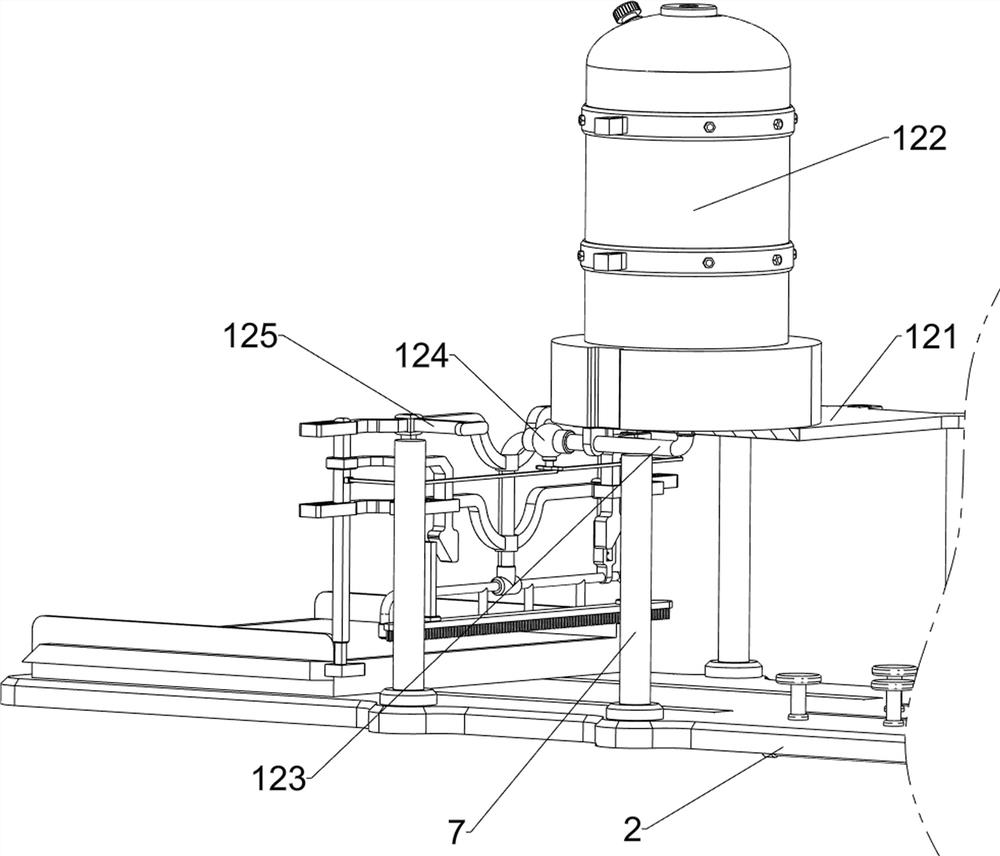

[0036] On the basis of embodiment 1, refer to figure 1 with Figure 7 As shown, also includes glue application mechanism 13, glue application mechanism 13 can make glue smear evenly on the lower plate of plywood, and glue application mechanism 13 includes the 3rd wedge block 131, the 4th spring 132, hairbrush 133 and back-moving spring 134, the inner upper part of telescopic rod 127 is equipped with a third wedge-shaped block 131, and the third wedge-shaped block 131 is slidably connected with the mounting frame 125, and the third wedge-shaped block 131 is connected with the mounting frame 125 with a fourth spring 132. The lower part of the frame 125 is slidingly provided with a brush 133, which can make the glue smear evenly, and a back-moving spring 134 is symmetrically connected between the top of the brush 133 and the mounting frame 125.

[0037] The telescopic rod 127 moves to the outside to drive the third wedge-shaped block 131 to move to the outside, and the third wed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com