Automatic plate arranging line

A technology of automatic arranging and board line, which is used in the joining of wooden veneers, glue guns, wood processing appliances, etc., which can solve the problems of low production efficiency and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

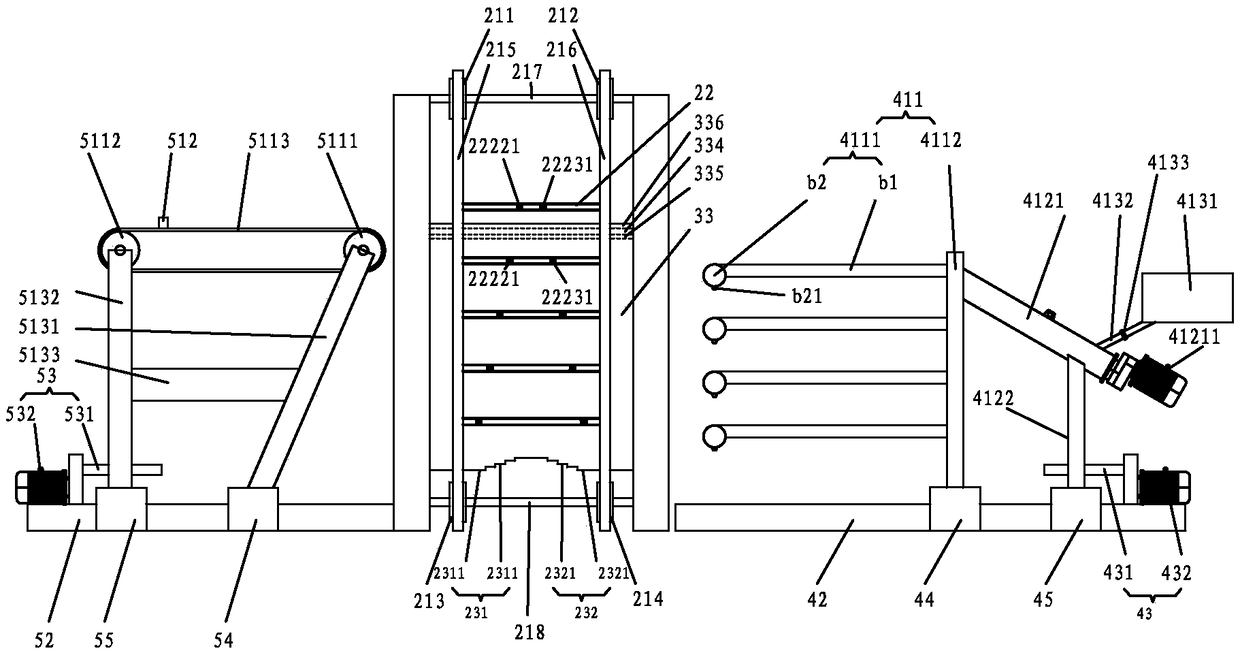

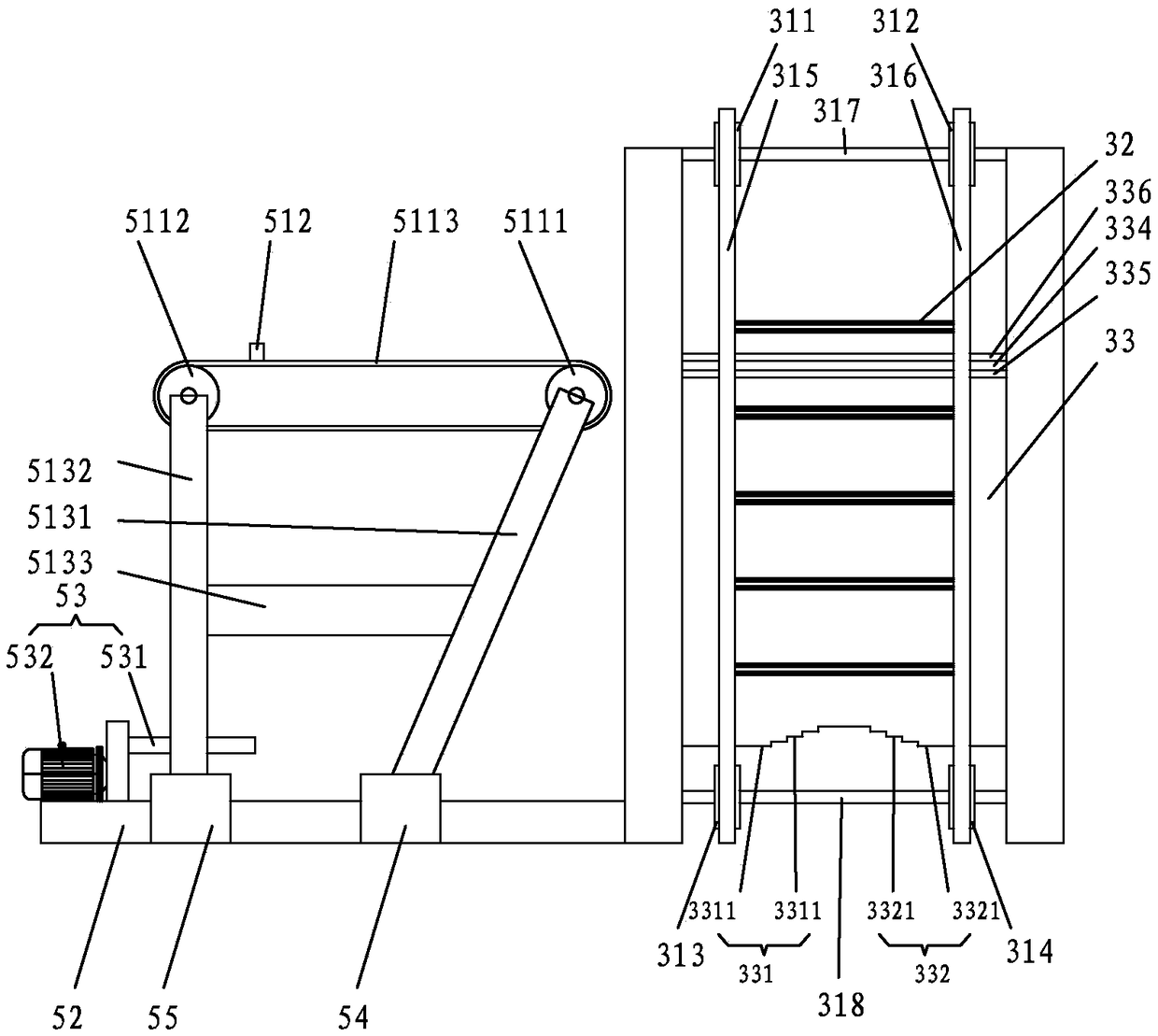

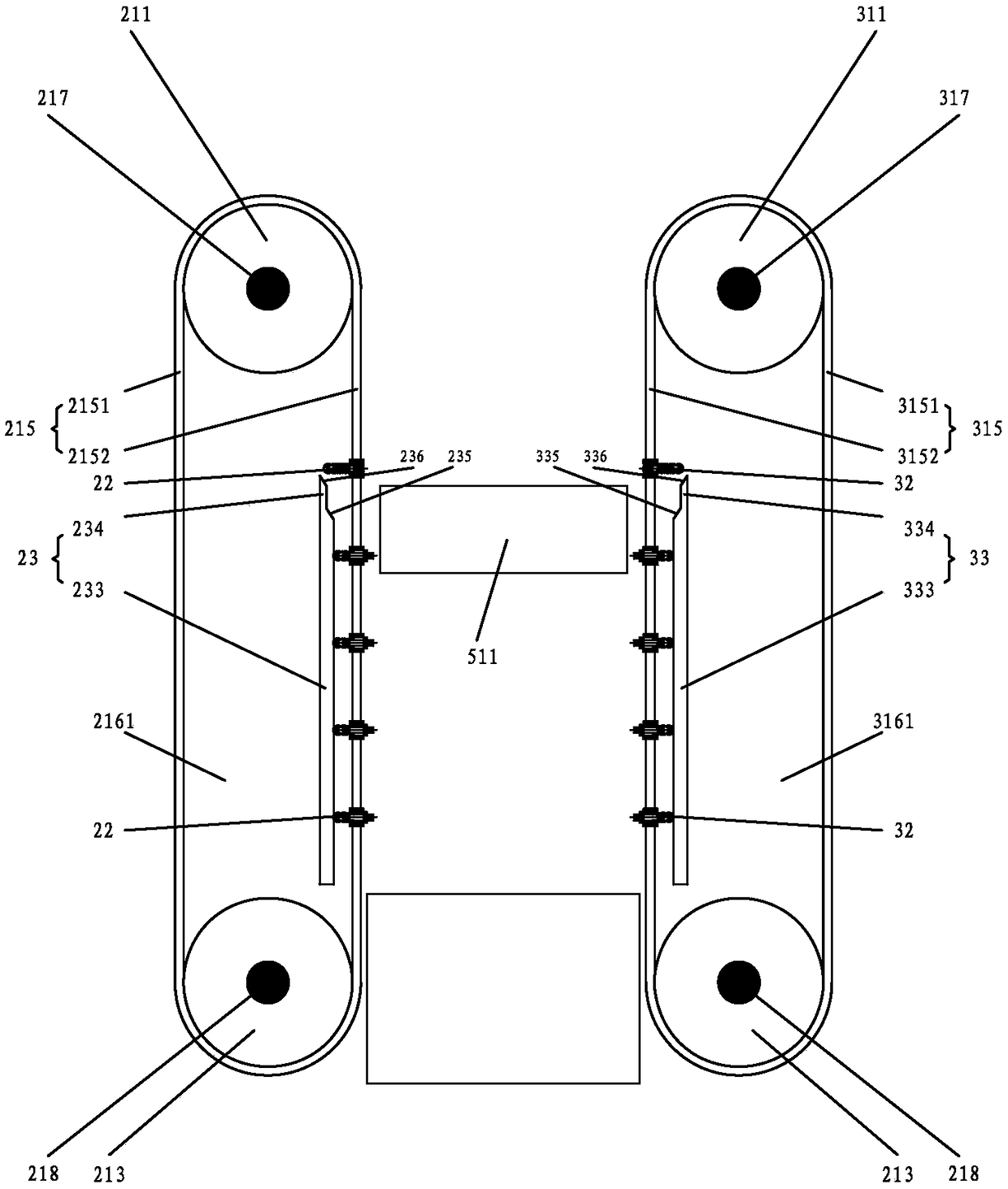

[0042] A kind of automatic plate arrangement line of the present invention, as Figure 1-9 As shown, it includes a panel arranging device for arranging the template blank 6, a gluing device for applying glue to the template blank 6, and a conveying device for transporting the template blank 6 to the panel arranging device; preferably, it also includes a panel arranging device , the controller for controlling the gluing device and the conveying device;

[0043] The template blank 6 after defining the arrangement has successively adjacent first edges, second edges, third edges and fourth edges;

[0044] The board arrangement device includes a first board row part corresponding to the first edge, and a second board row part corresponding to the third edge;

[0045]The first row of boards includes a vertically arranged first chain runn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com