Method for moving connecting and cutting in woodworking

A woodworking and material cutting technology, which is applied in the direction of wood processing equipment, wooden veneer joints, manufacturing tools, etc., can solve the problems of non-continuity of joining wood and affecting the efficiency of wood joining, so as to improve the efficiency of butt jointing, good continuity, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

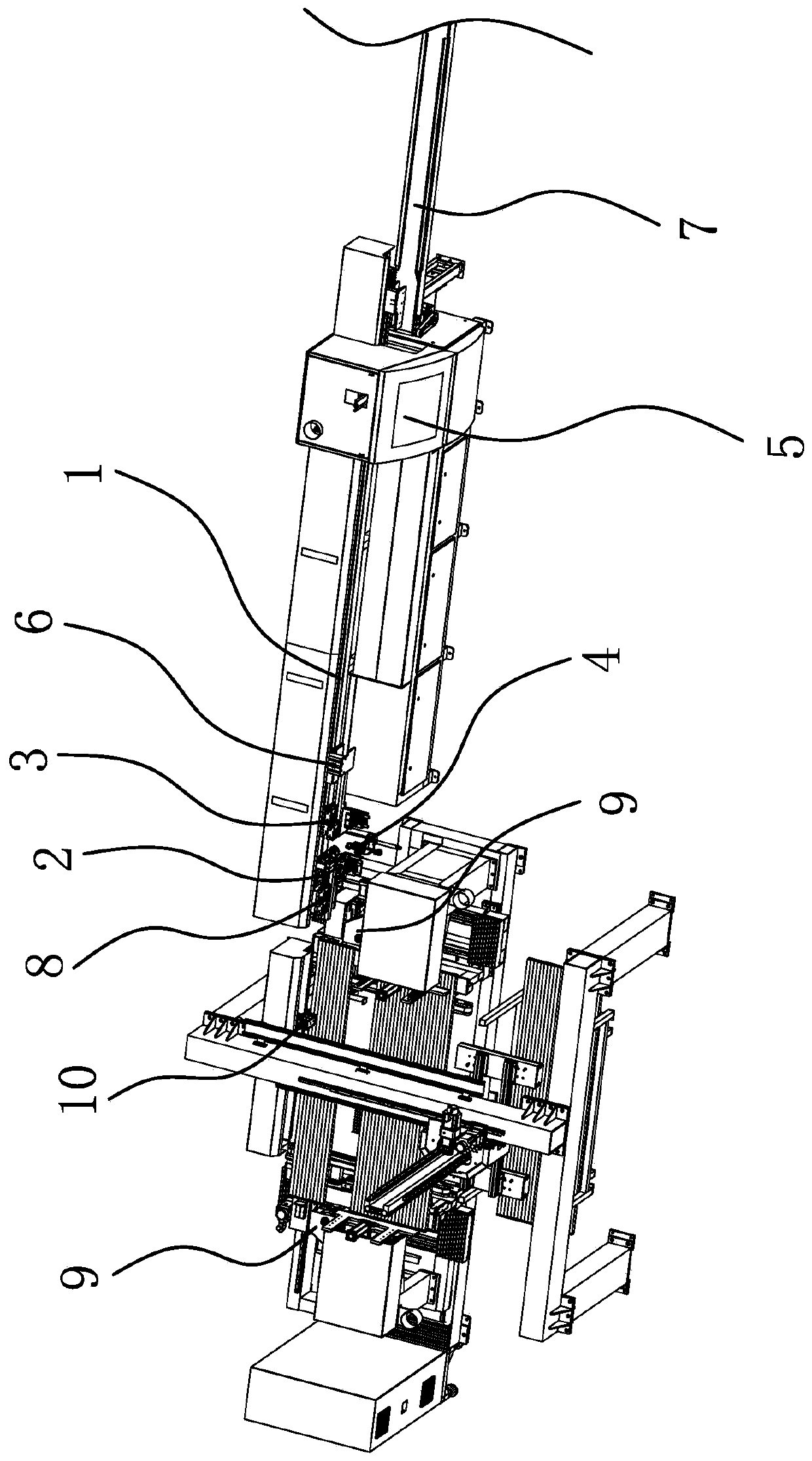

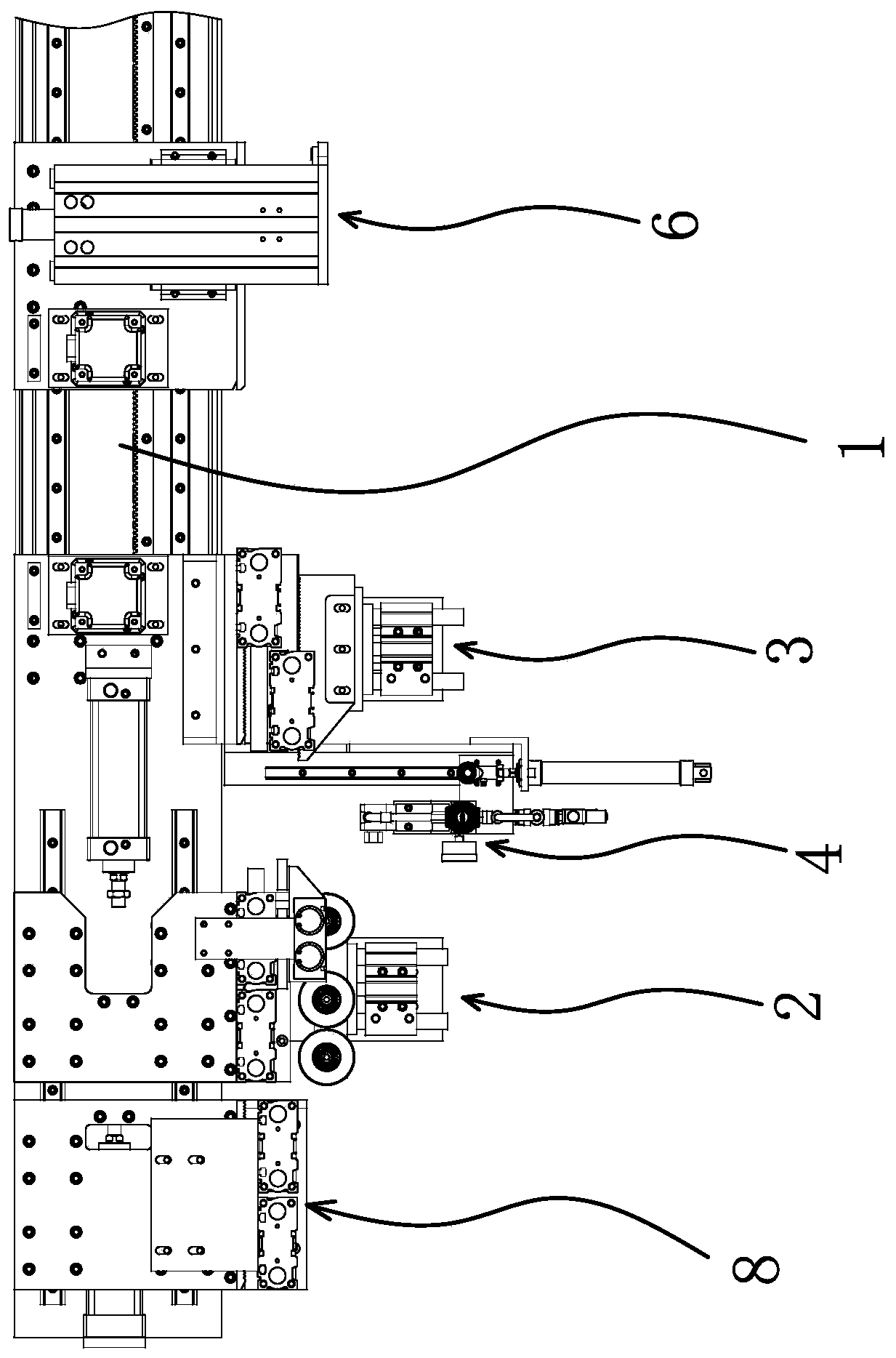

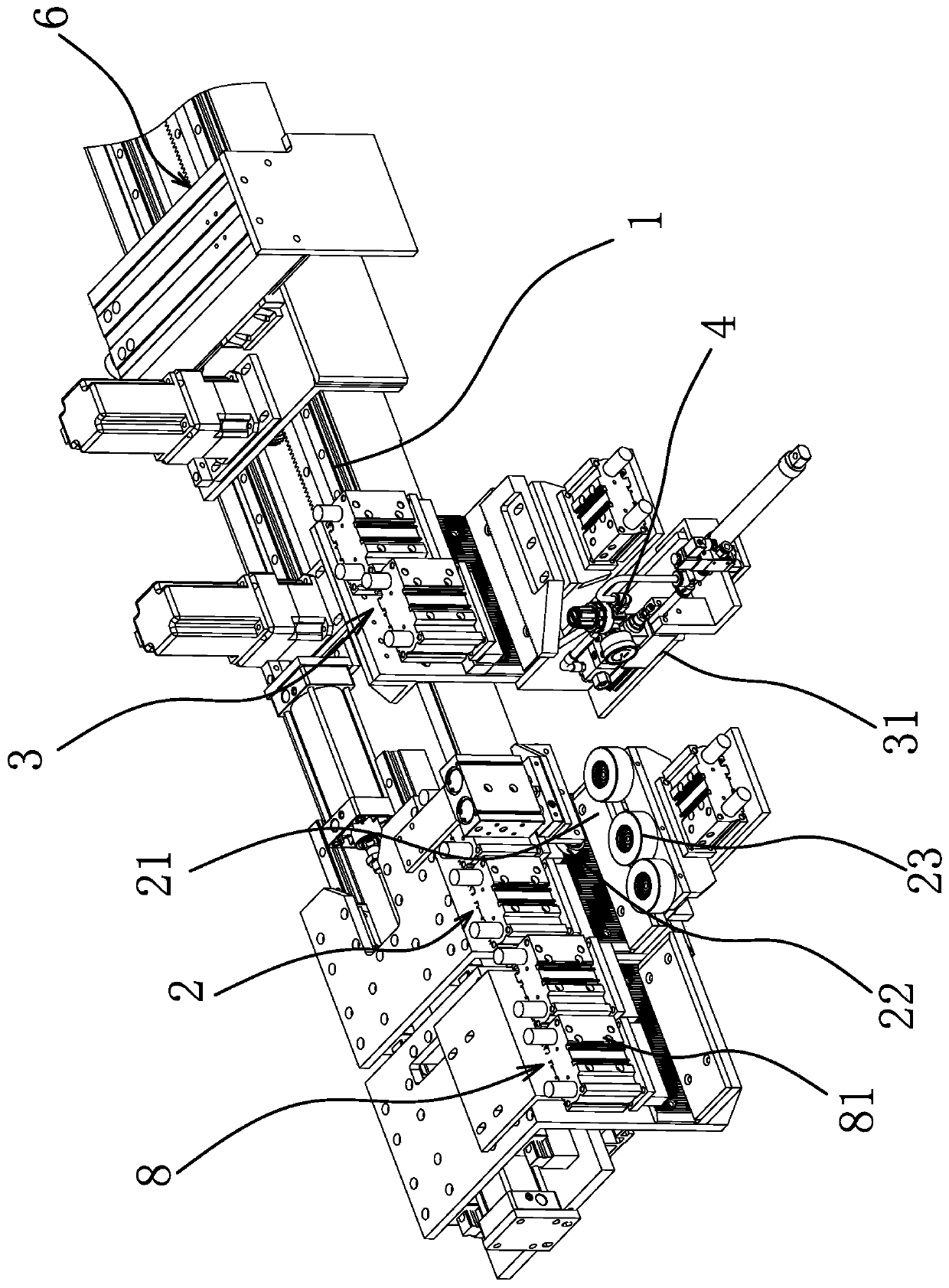

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0033] Such as Figure 1-4 As shown, the woodworking method for moving materials and cutting materials, the method includes the following steps:

[0034] a Feeding: a machine platform 1 is provided with a clamp assembly one 2 and a clamp assembly two 3 on the machine platform 1, and the wooden strip two behind the comb teeth at both ends is moved to the clamp assembly two 3 at the initial position, so that the clamp assembly Two 3 clamp the wooden strip 2, and move the wooden strip 1 behind the comb teeth at both ends to the clamp assembly 1 2 located in the initial position, so that the clamp assembly 1 2 clamps the wooden strip 1;

[0035] b Mobile material receiving: There is also a glue sprayer 4 on the machine platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com