Gluing device and gluing method for plate combined machining

A technology of composite processing and gluing device, which is applied in wood processing appliances, adhesive application devices, glue guns, etc., and can solve problems such as gluing dead corners and composite problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

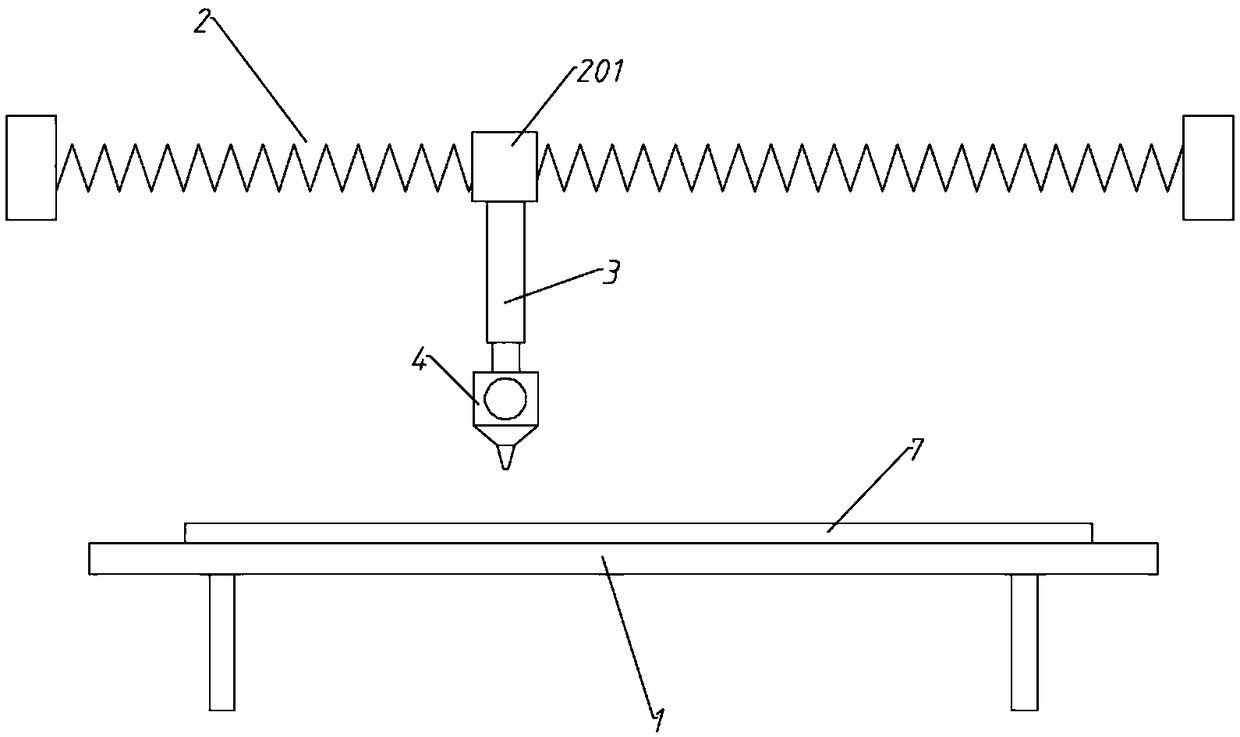

[0032] A gluing device for plate composite processing, comprising a container table 1, a linear module 2, a positioning cylinder 3, and a gluing component 4; the linear module 2 is arranged above the container table 1, and the container table 1 is to be placed Glue-coated plate 7; the movement direction of the sliding table 201 of the linear module 2 is parallel to the length of the plate to be coated 7, and the movement path of the sliding table 201 is greater than the length of the plate to be coated 7; the sliding table 201 of the linear module 2 is directed A position adjustment cylinder 3 is connected below, and the telescopic end of the position adjustment cylinder 3 extends downward and is connected to the glue application assembly 4.

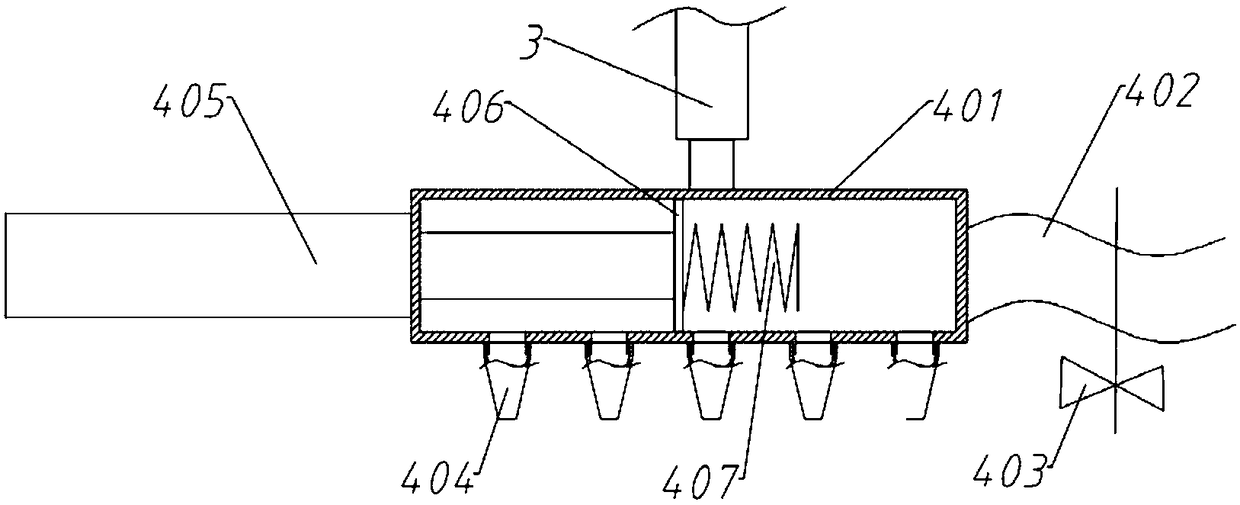

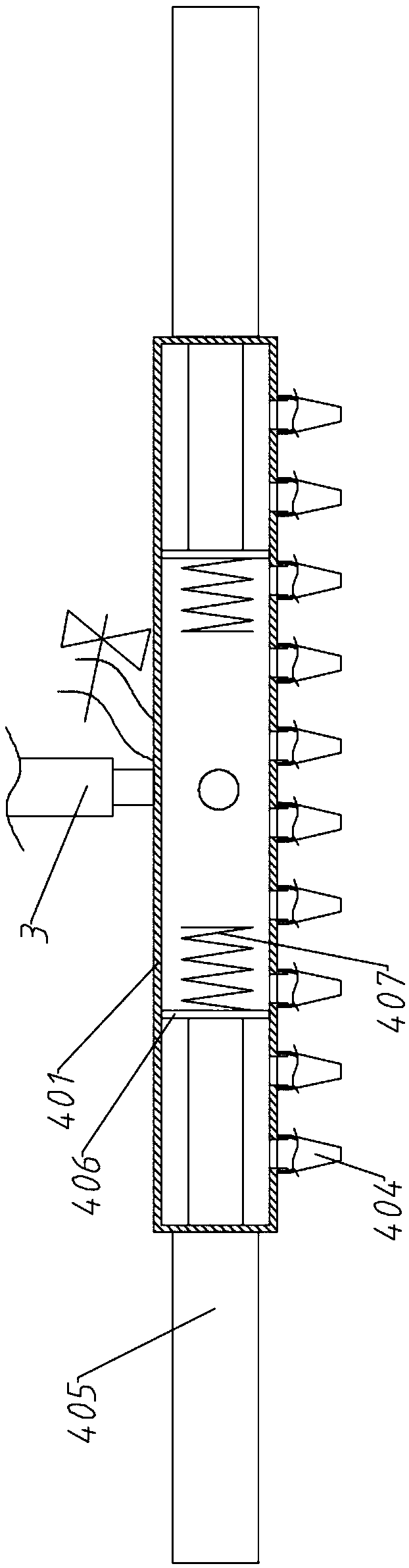

[0033] The gluing assembly 4 includes a cylinder 401, a pitch-adjusting cylinder 405, a piston plate 406, and a glue nozzle 404. The length of the cylinder 401 is greater than the width of the plate 7 to be glued. The cylinder 401 is paralle...

Embodiment 2

[0035] The difference from Embodiment 1 is that the glue application assembly 4 includes a cylinder 401, a pitch-adjusting cylinder 405, a piston plate 406, and a glue nozzle 404. The cylinder 401 is parallel to the width direction of the plate to be coated 7 and the length of the cylinder 401 It is larger than the width of the plate to be coated 7; both ends of the cylinder 401 are provided with a pitch cylinder 405, and the telescopic end of the pitch cylinder 405 extends into the cylinder 401 and is connected with a piston plate 406. The piston plate 406 is provided with spring heating Ring 407, the bottom end of the cylinder 401 is evenly screwed with a glue nozzle 404; the middle section of the cylinder 401 is connected to the glue bucket through a glue pipe 402, and the glue pipe 402 is equipped with a glue valve 403.

[0036] The double-ended setting of the pitch-adjusting cylinder 405 is adopted, which makes the adjustment interval more flexible.

Embodiment 3

[0038] The difference from Embodiment 1 or 2 is that it also includes a controller, the linear module 2, the position adjusting cylinder 3, the pitch adjusting cylinder 405, the spring heating coil 407, and the glue inlet valve 403 are respectively connected to the controller.

[0039] The controller model is Texas Instruments MSP430, and the linear module 2 uses silver KK100. Since the technical effect achieved by embodiment 3 is the most, this embodiment is used for explanation, that is, the glue application method of this device:

[0040] S1: Place the plate 7 to be glued on the holding table 1, and keep the length direction of the plate parallel to the movement path of the linear module sliding table 201;

[0041] S2, according to the position, length and width of the plate 7 to be coated, adjust the effective spray interval of the glue application assembly 4, and adjust the effective spray interval of the glue application assembly 4;

[0042] Control the distance adjustment cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com