Equipment and process for processing bamboo split roll

A technology of bamboo strip rolls and bamboo strips, which is applied in the processing of bamboo strip rolls, processing of forest crops, and processing of forest crops. It can solve the problem of broken wires, insufficient bonding of the front and rear bamboo strips, and slits in cutting. and other problems to achieve the effect of improving the glue spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

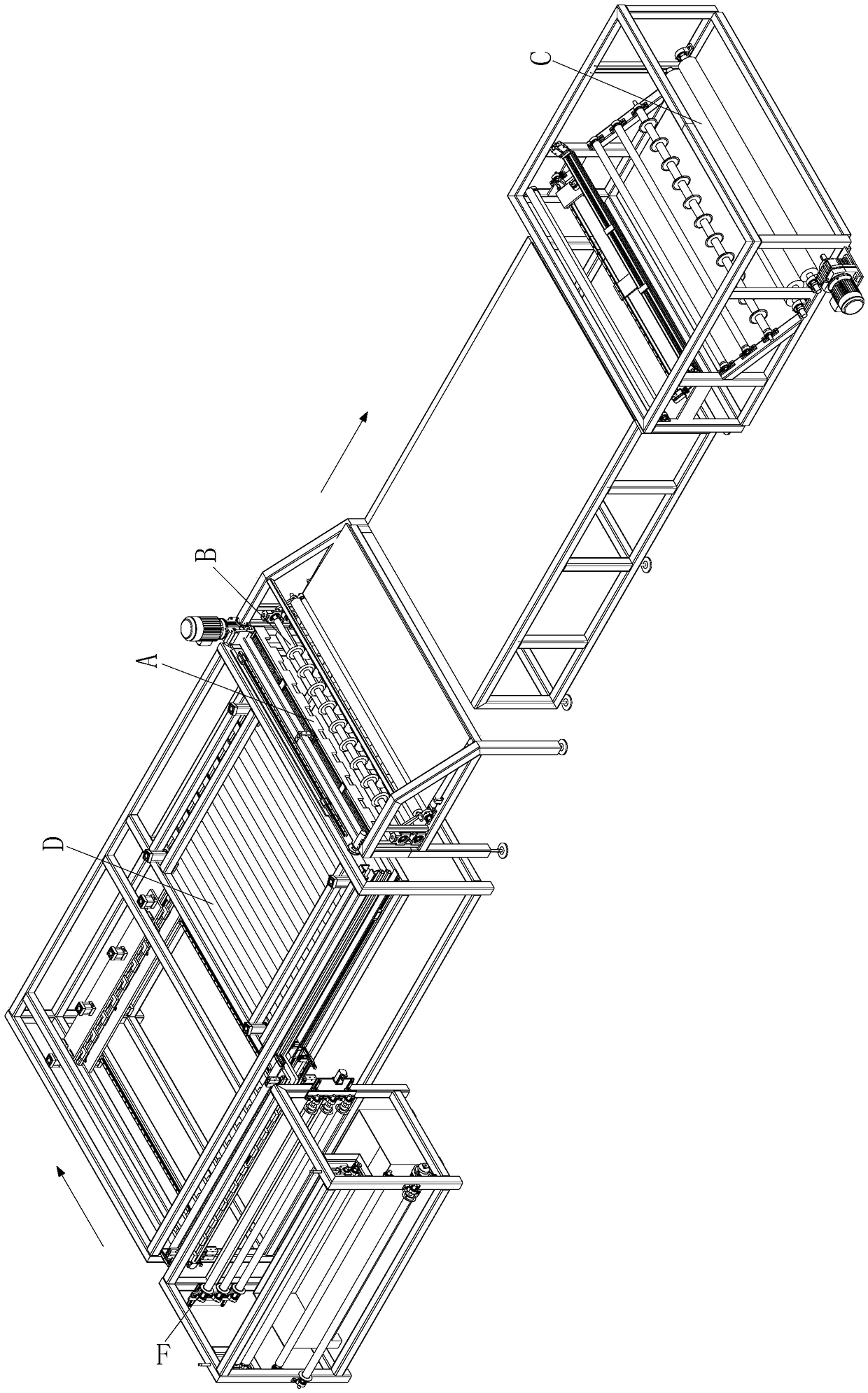

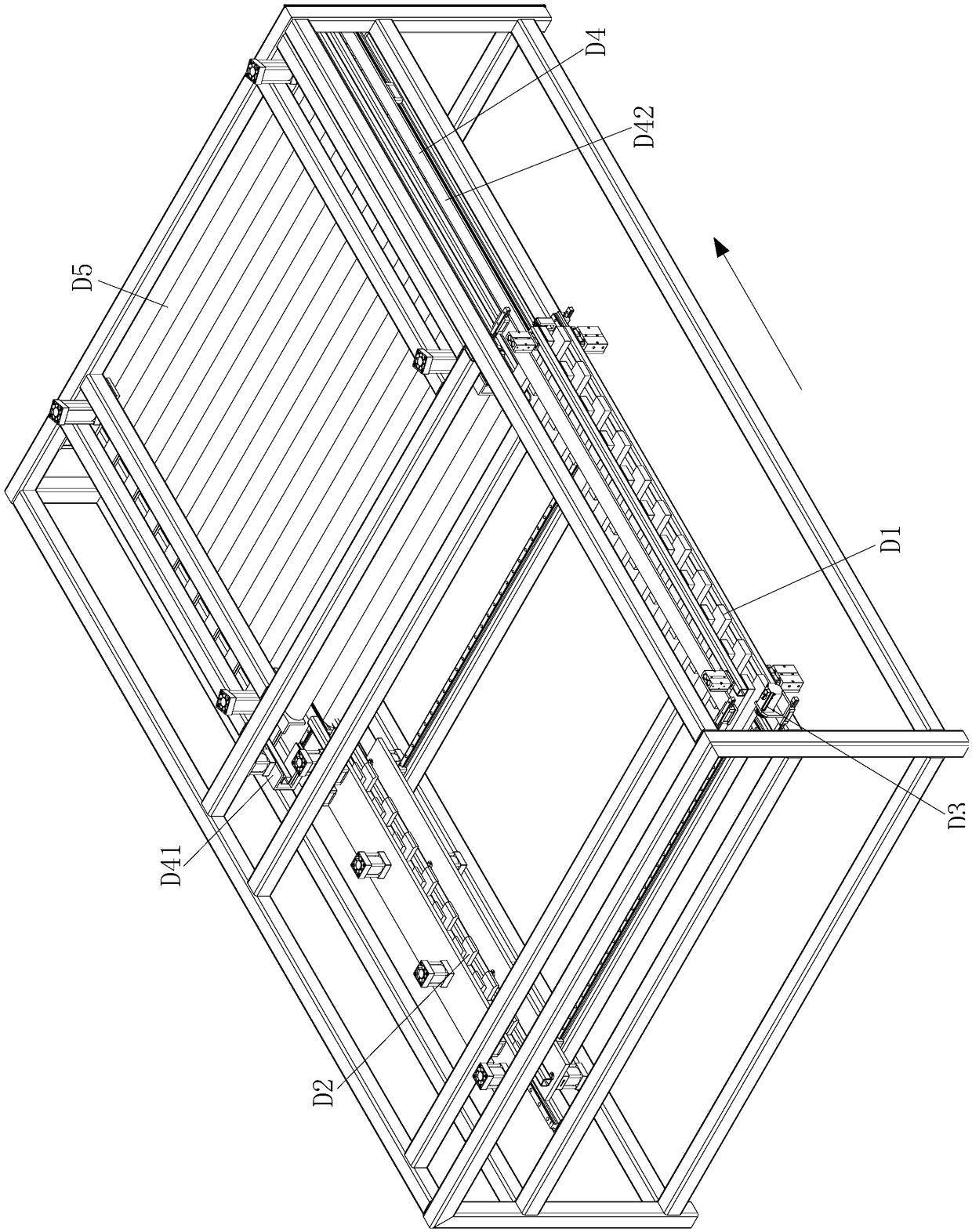

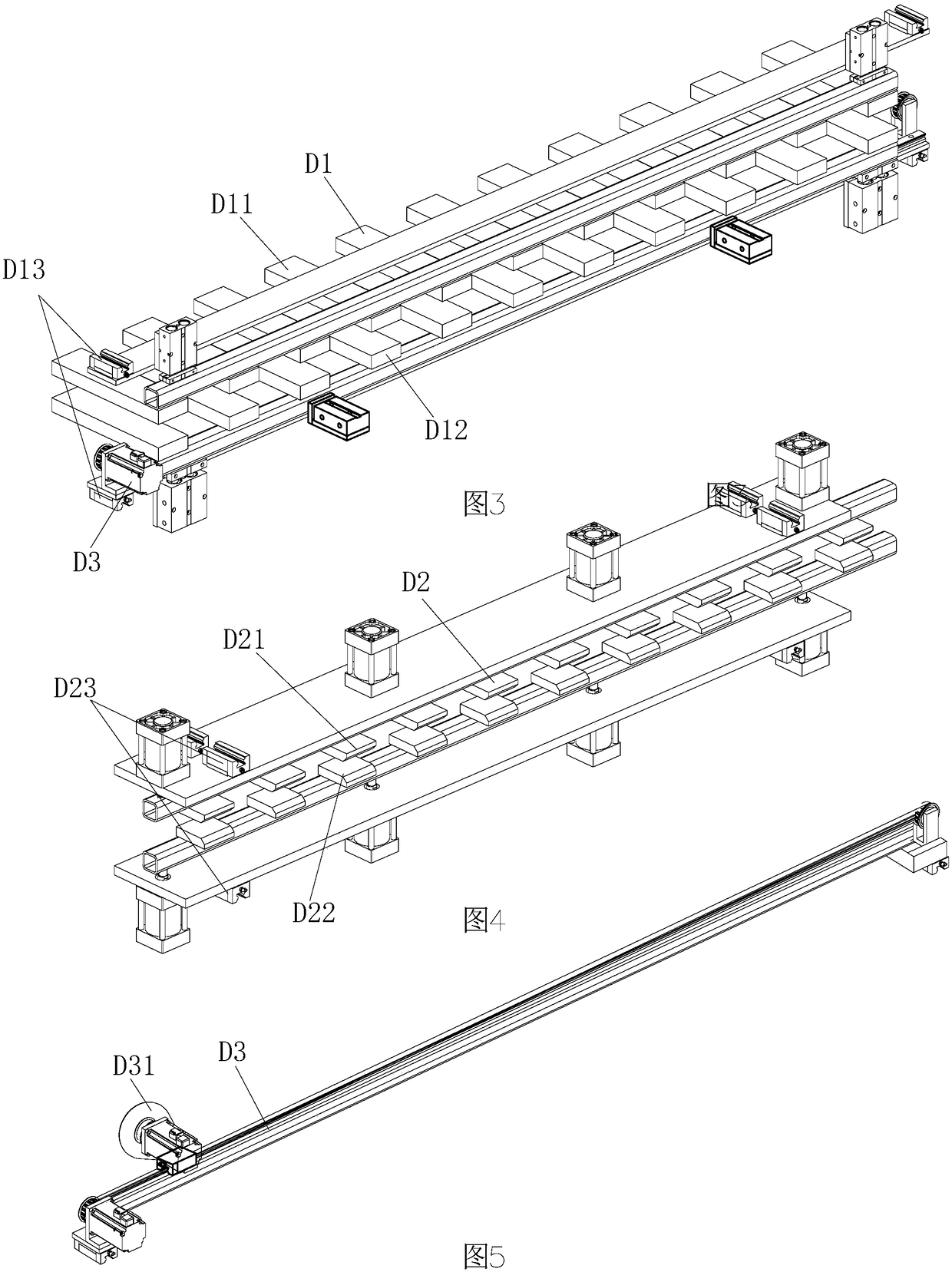

[0083] Examples, see Figure 1 to Figure 18 shown.

[0084] The equipment dedicated to processing bamboo strip rolls in this embodiment includes a feeding device F for conveying the bamboo strip curtain along its warp direction to the weaving line 2 and cutting off the material. After the bamboo strip curtain is broken, the bamboo strip sheet 3 is formed, and the bamboo strip curtain is cut off to form a bamboo strip sheet 3. An axial feeding device D for conveying the bamboo strips 3 along the length direction of the bamboo strips 1, the conveying directions of the said feeding device F and the axial feeding device D are perpendicular to each other, and it is characterized in that: it also includes two pieces of ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com