Patents

Literature

45results about How to "Guaranteed winding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

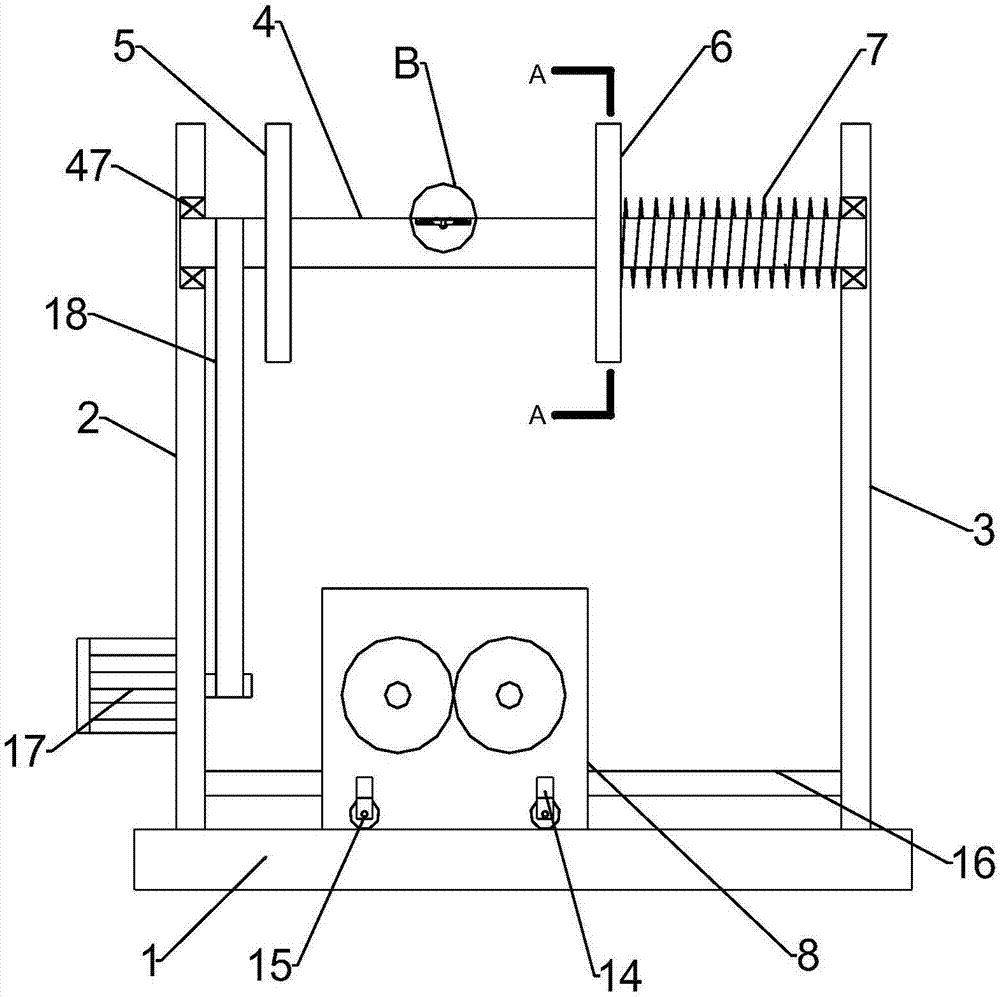

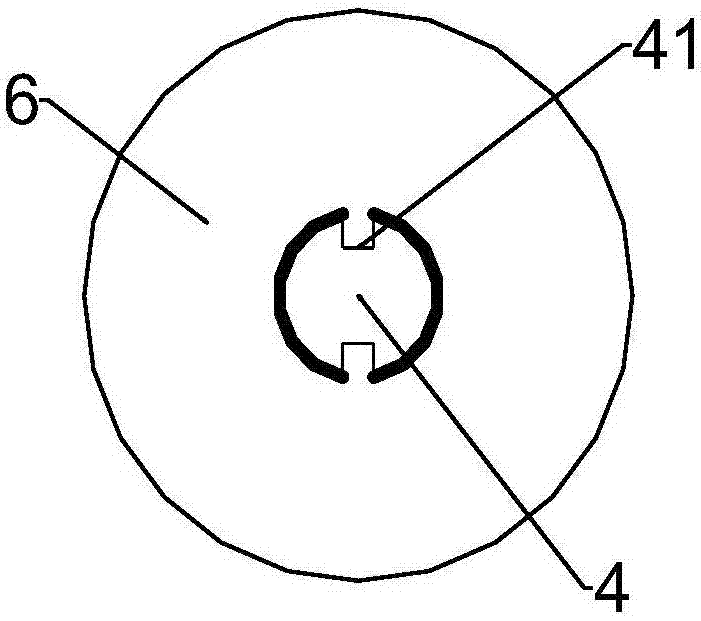

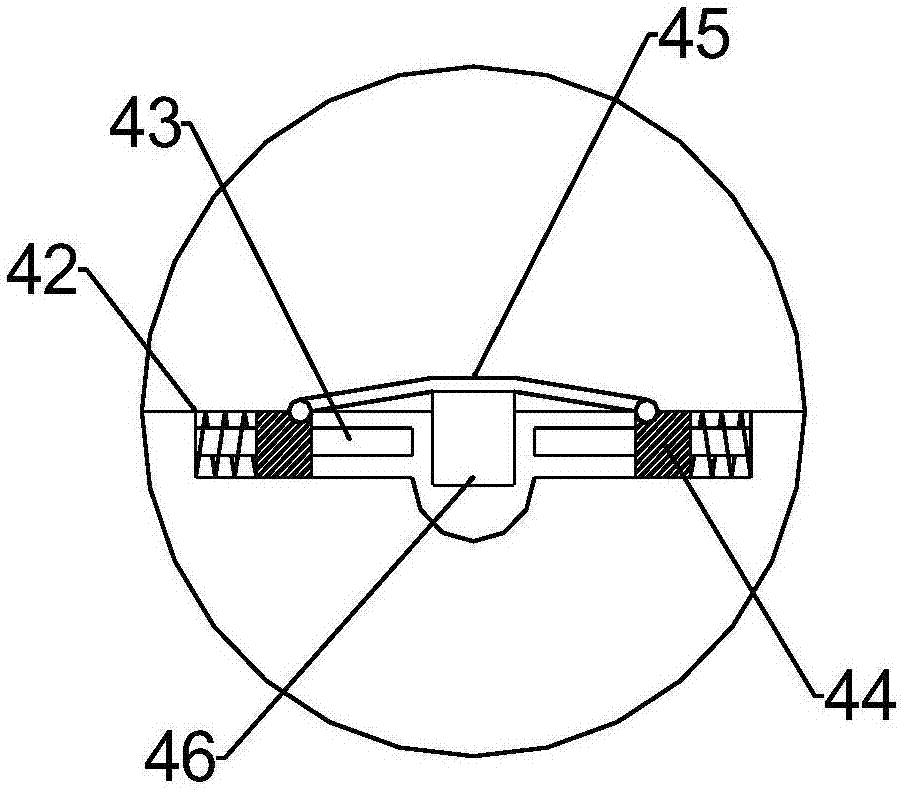

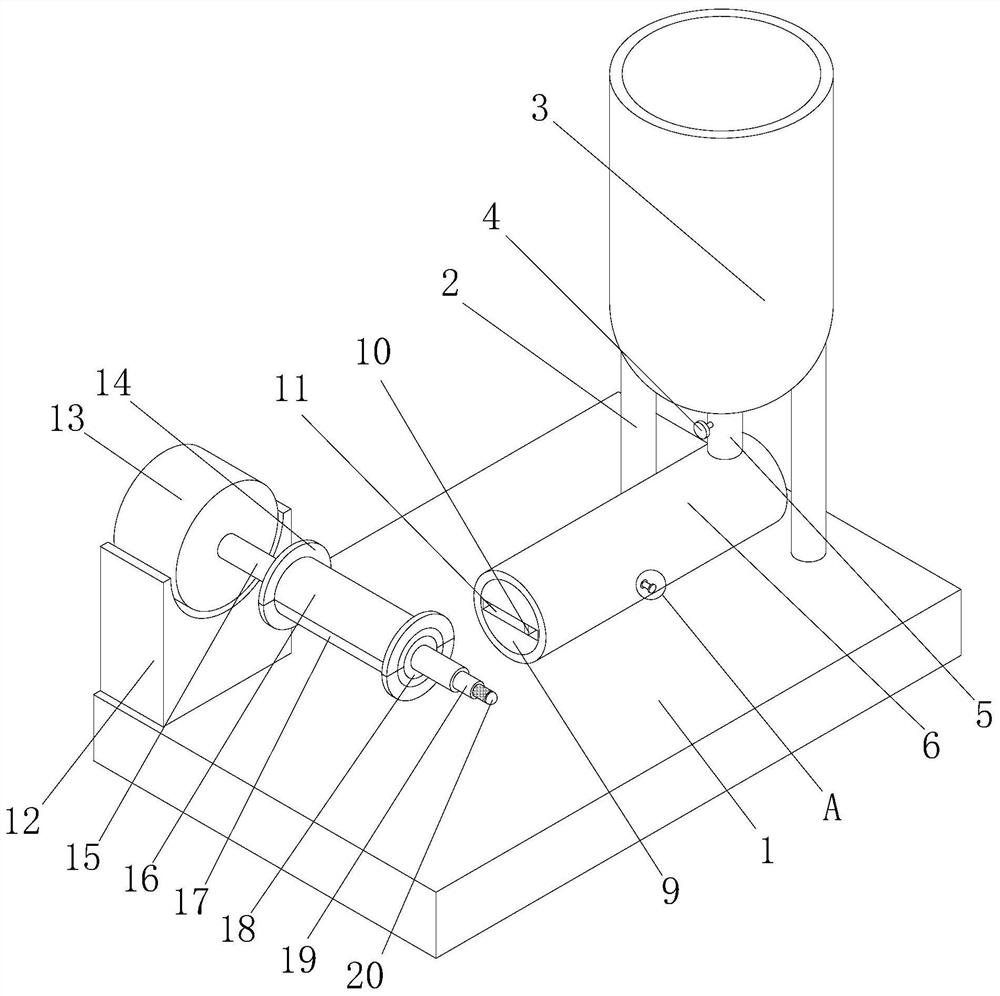

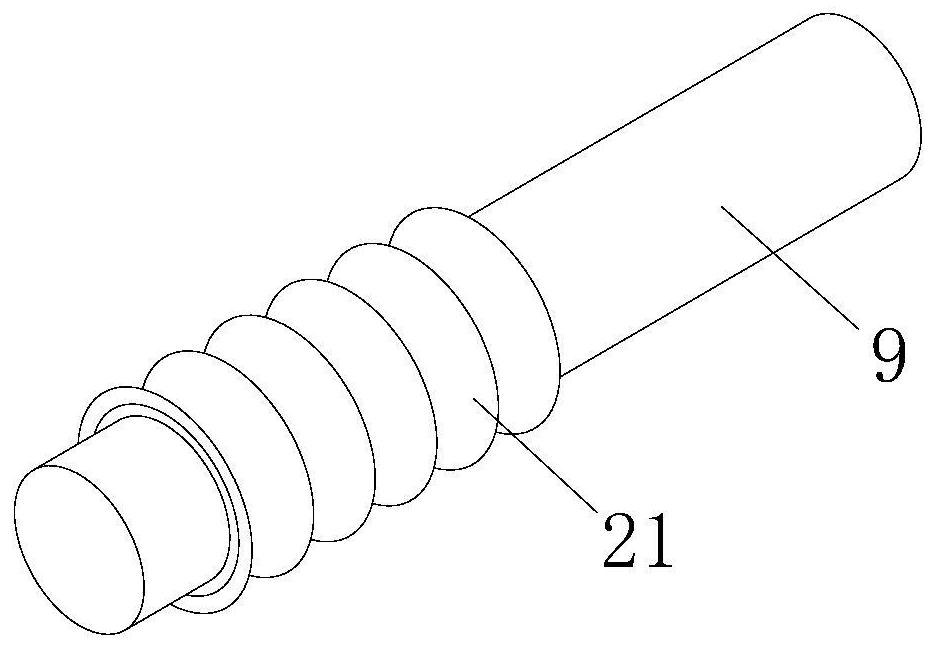

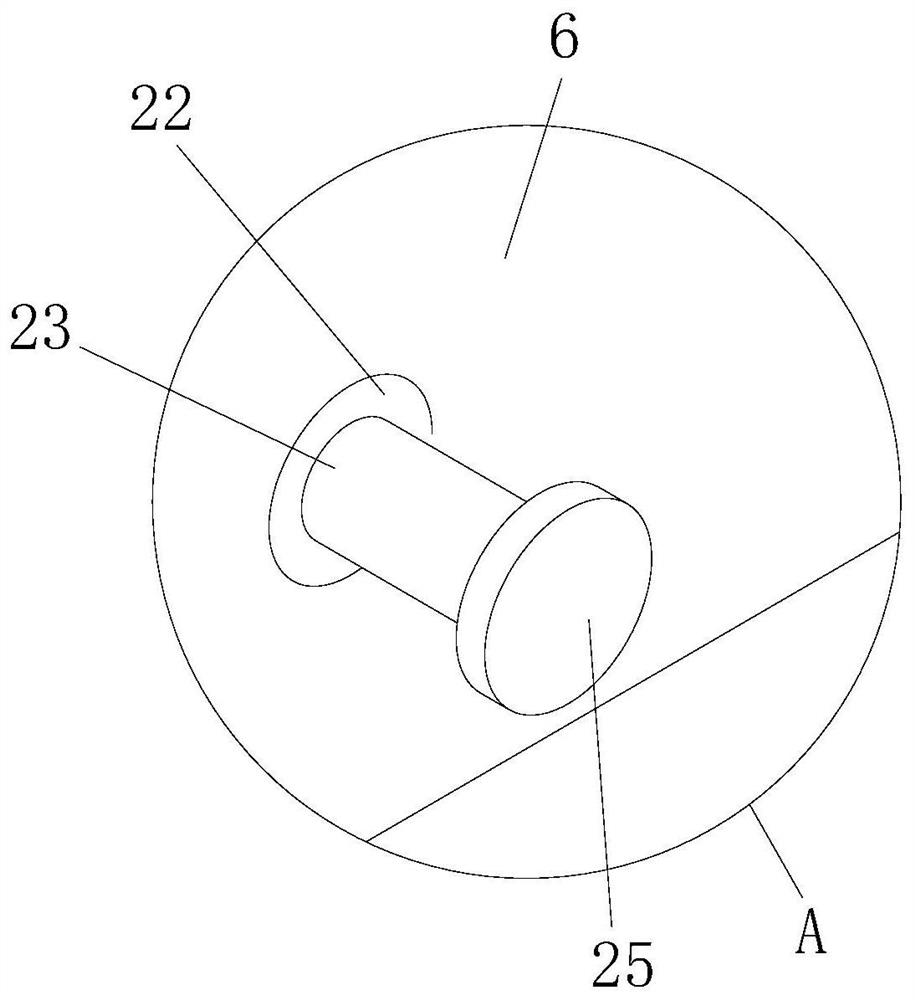

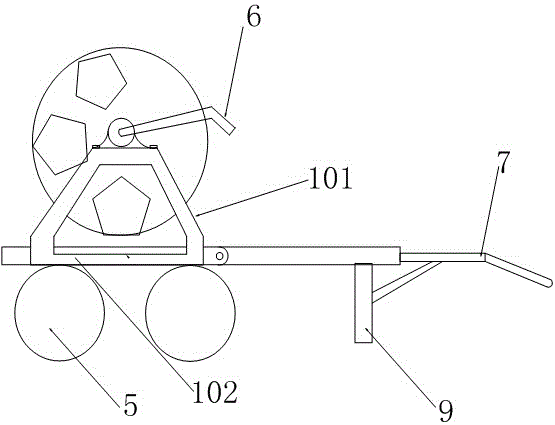

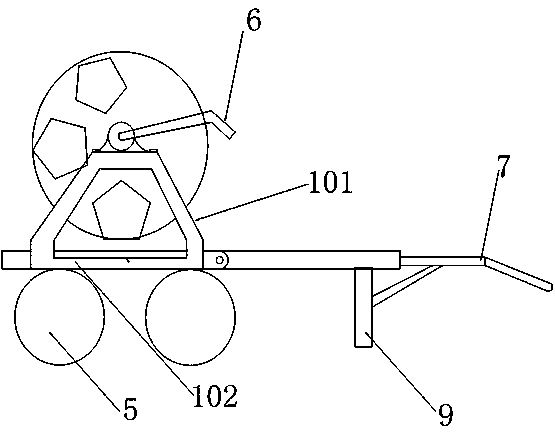

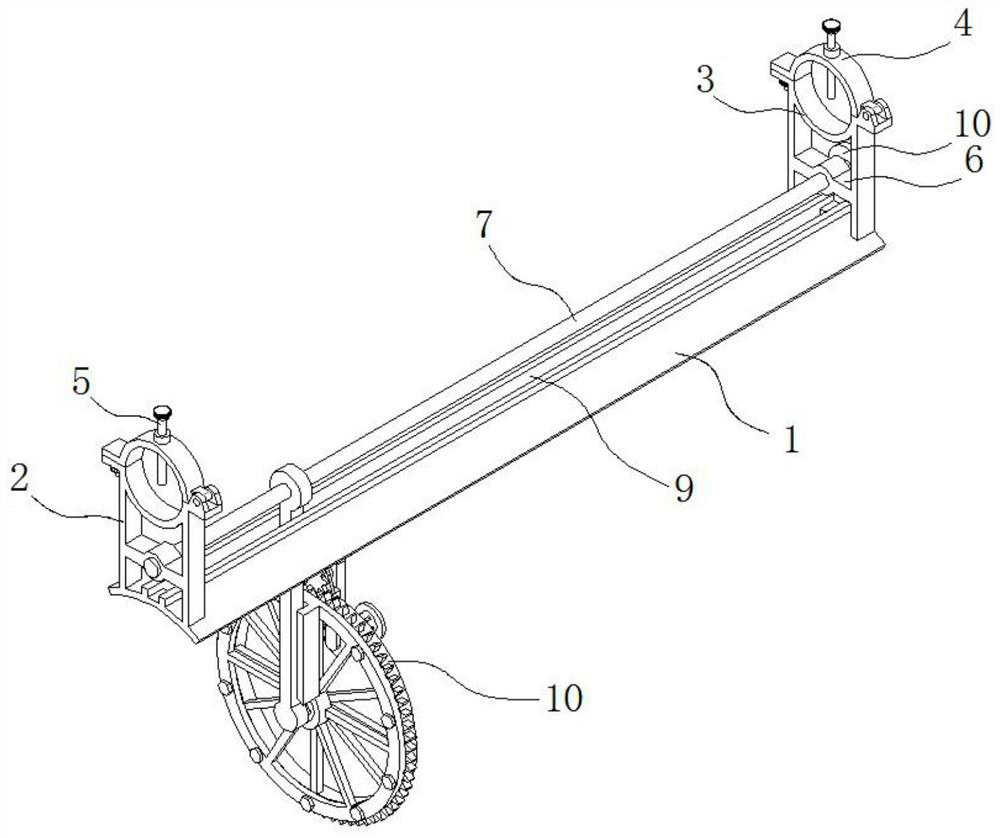

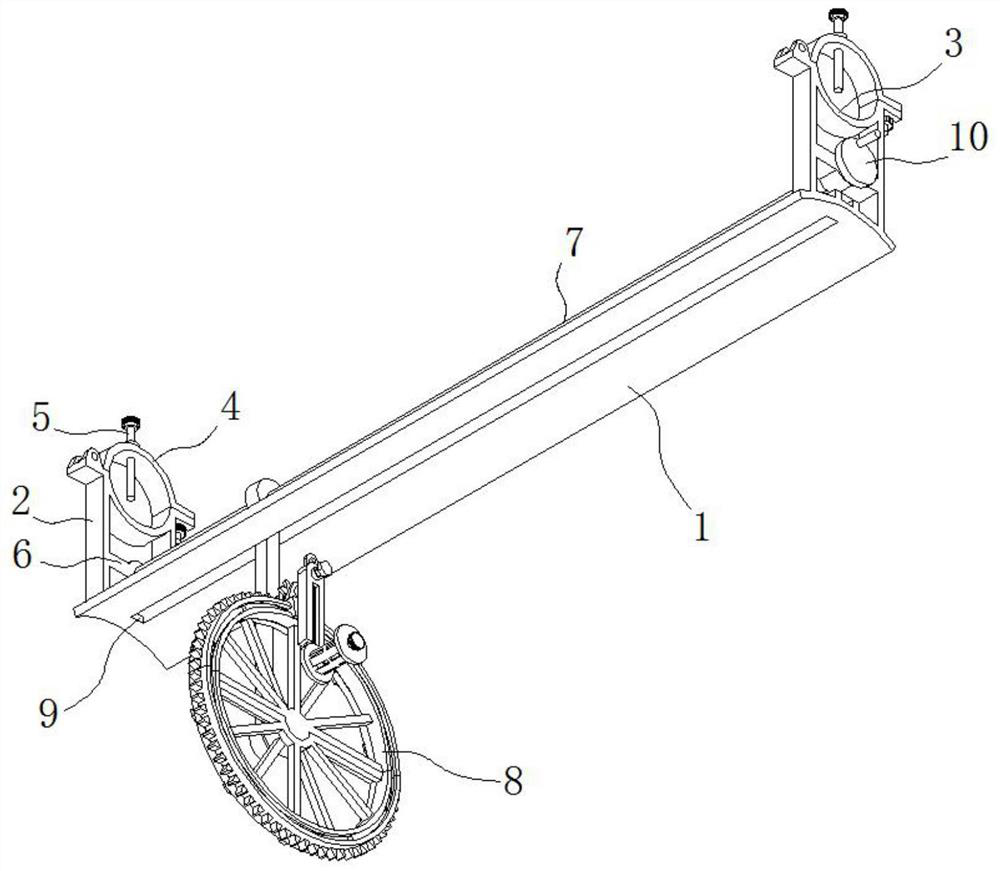

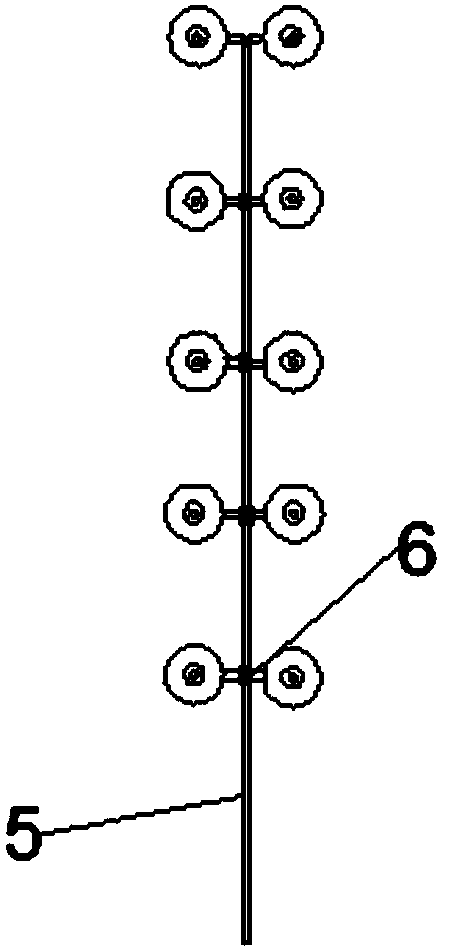

Waste power cable winding and recycling device

InactiveCN107473016AGuaranteed winding efficiencyIncrease storage capacityFilament handlingPower cableTransmission belt

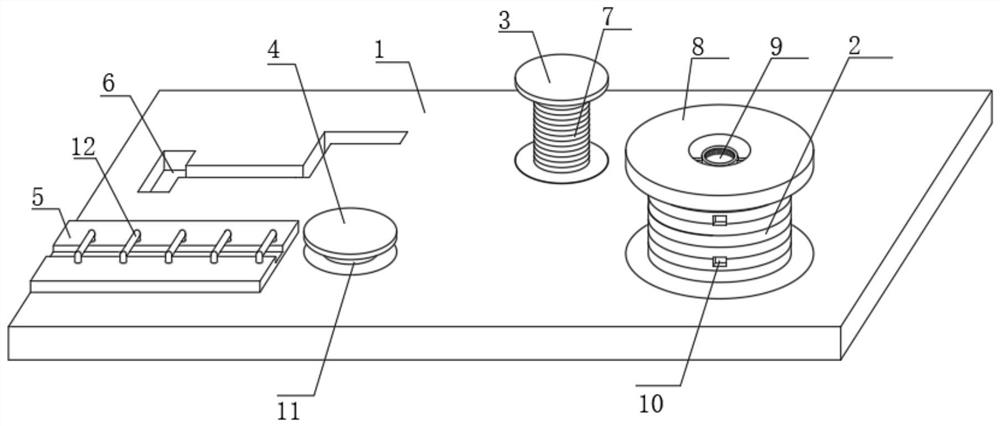

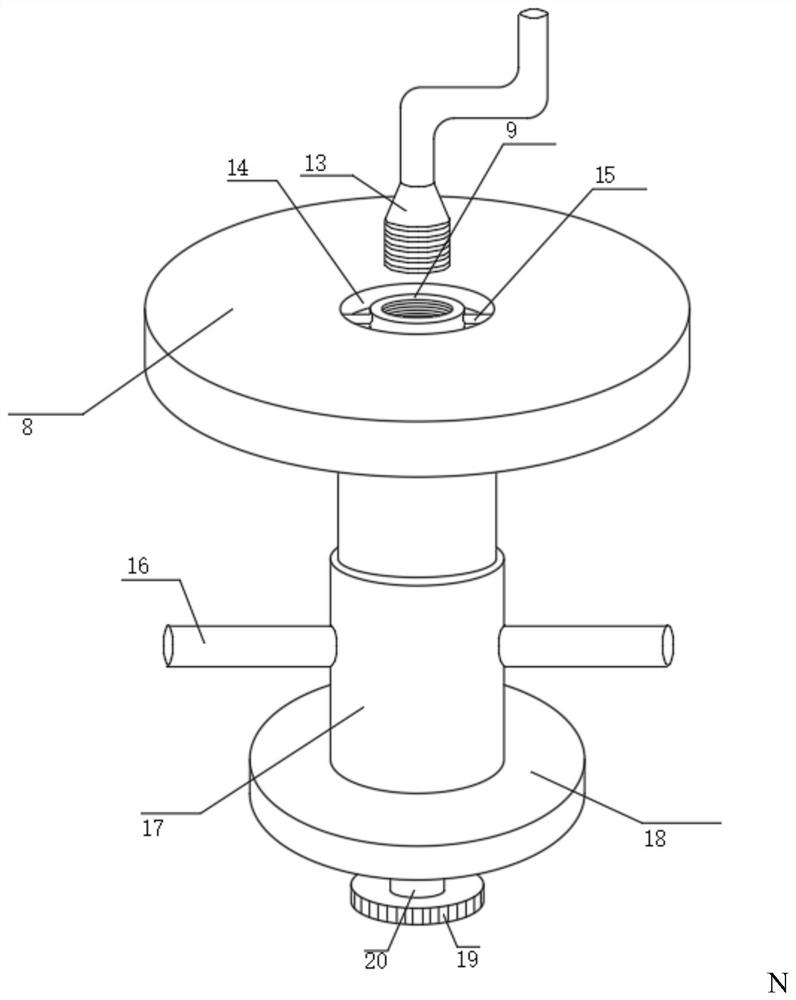

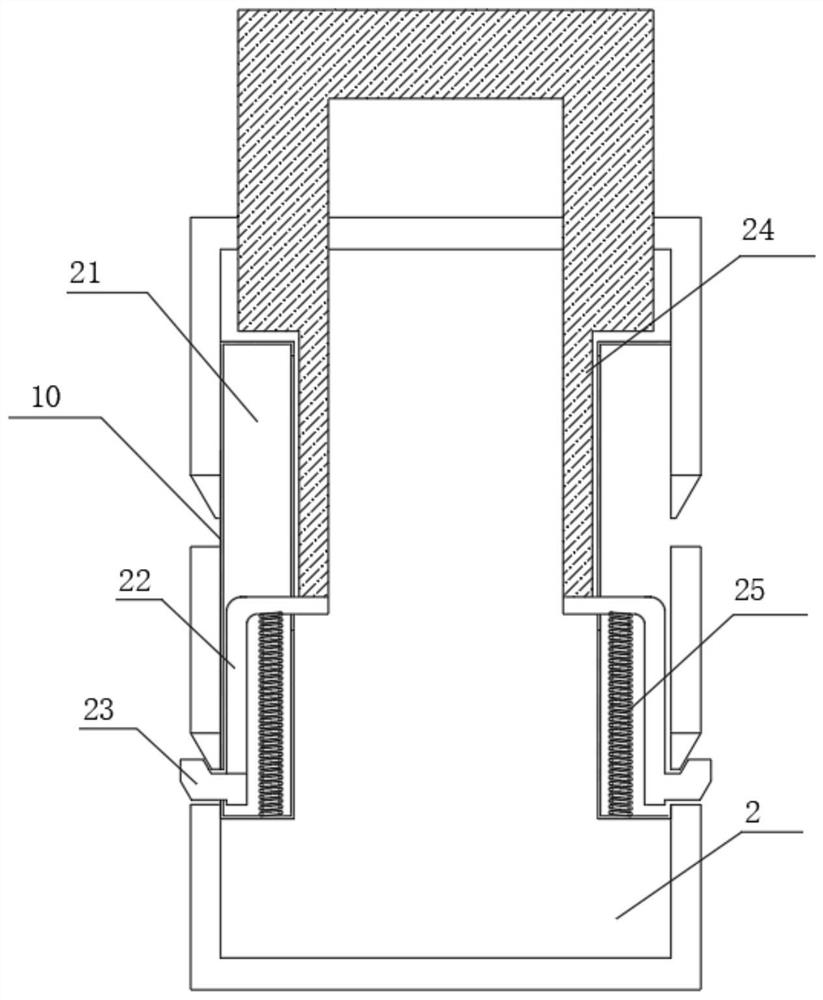

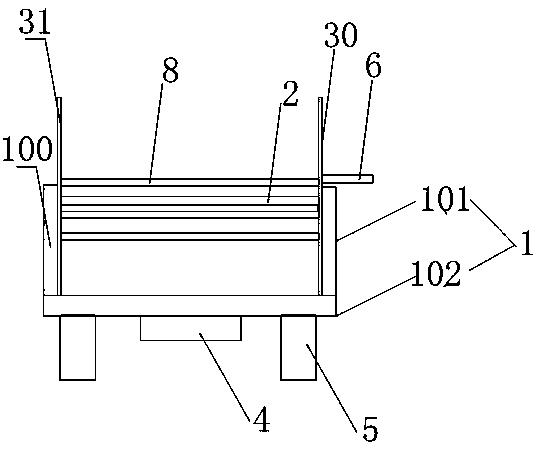

The invention discloses a waste power cable winding and recycling device. The waste power cable winding and recycling device comprises a bottom plate, a left vertical rod, a right vertical rod, a horizontal beam rod, a left limiting baffle and a right limiting baffle, and the bottom plate is provided with the left vertical rod and the right vertical rod. The horizontal beam rod and a containing sliding rod are arranged between the left vertical rod and the right vertical rod. The horizontal beam rod is provided with a sliding groove, a fixing groove, a sliding rod, a sliding block, a connecting rod, a pressing block, a rotation bearing, a left limiting baffle, a right limiting baffle and a compression spring. A sliding containing plate is arranged on the periphery of the containing sliding rod and provided with a rotation shaft, a transmission gear, a limiting wheel, a limiting groove, a first motor, support rods and walking wheels. A second motor and a transmission belt are arranged on the left vertical rod. The waste power cable winding and recycling device can fix the tail end of a cable and rapidly wind the cable, automatic adjustment can be conducted according to the cable winding amount, meanwhile, the sliding containing plate and the limiting wheels are additionally arranged for promoting cable taking and using, and the using efficiency is improved.

Owner:孙文站

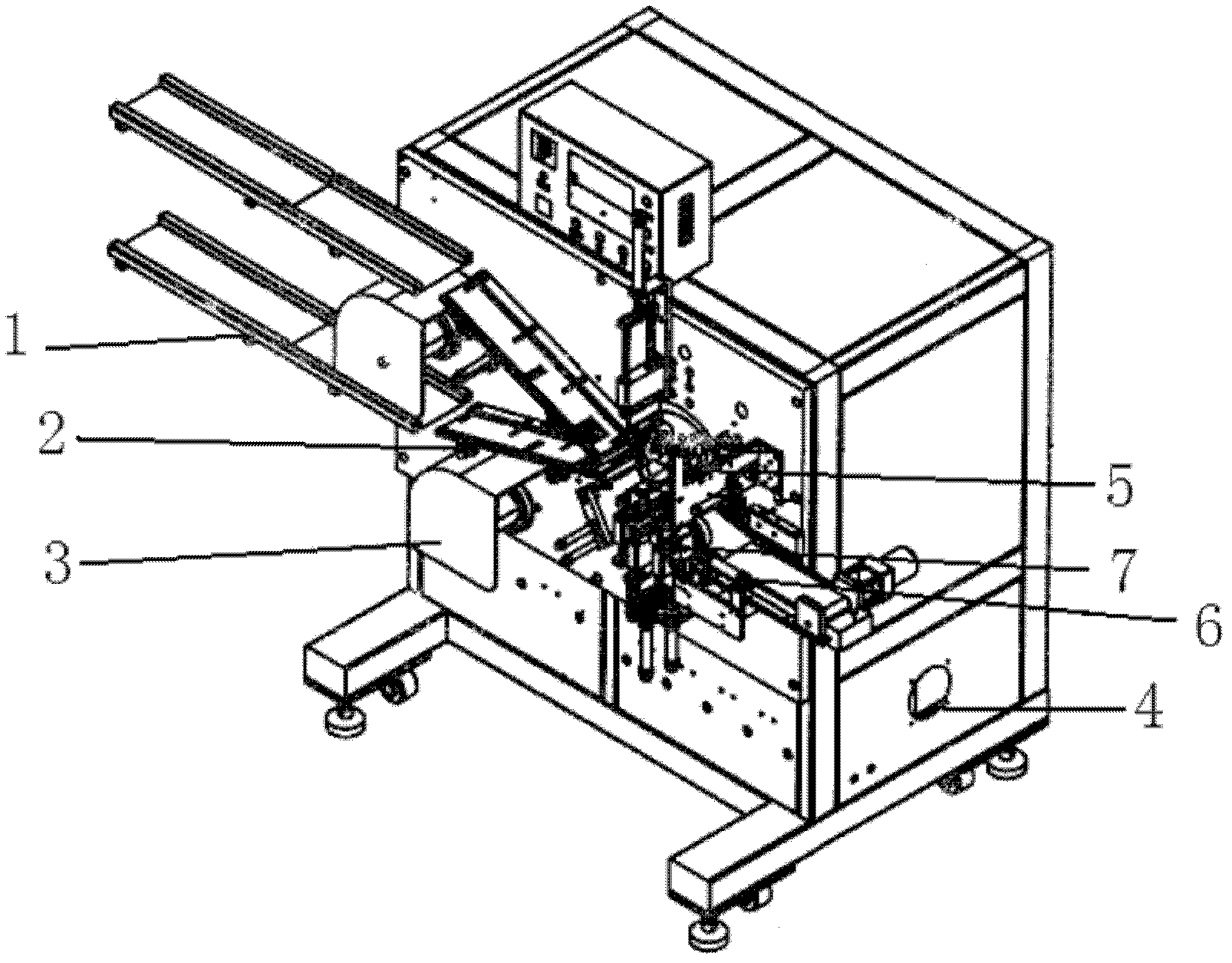

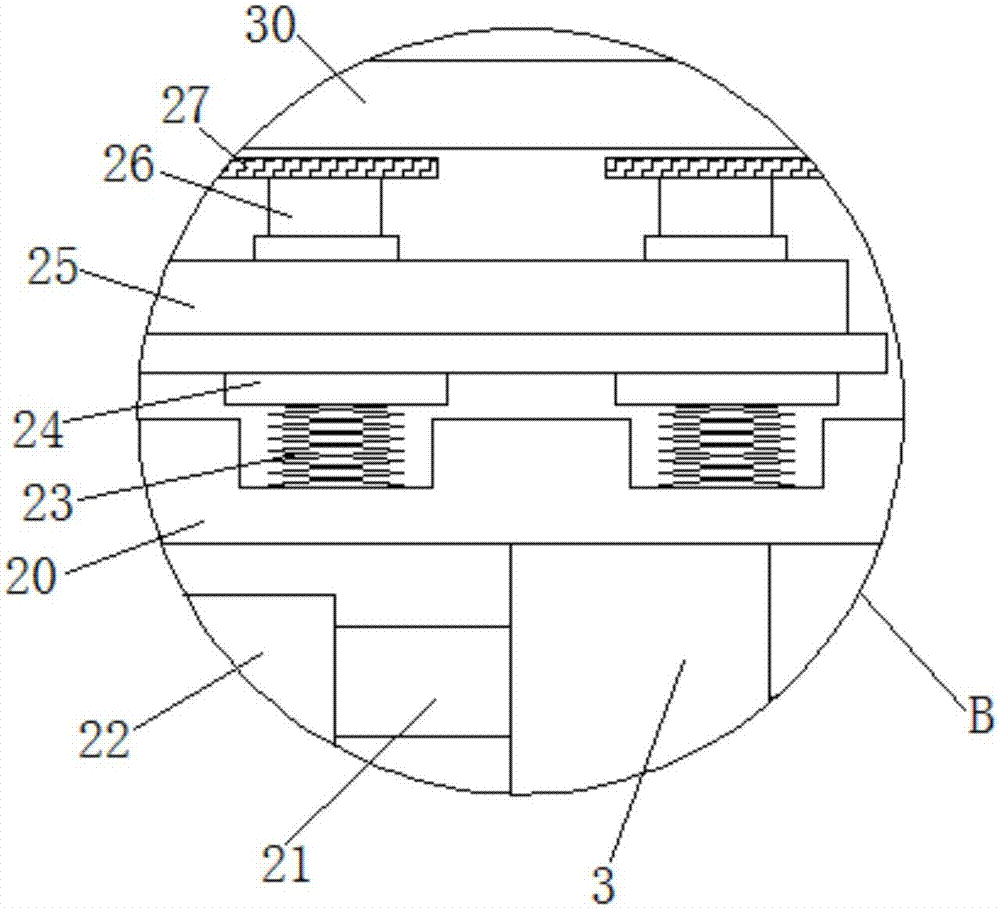

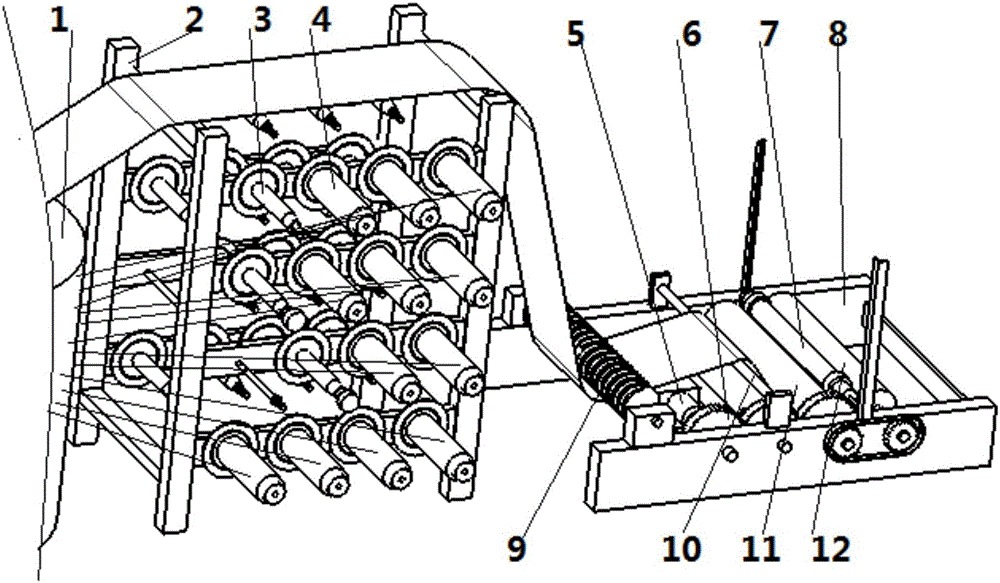

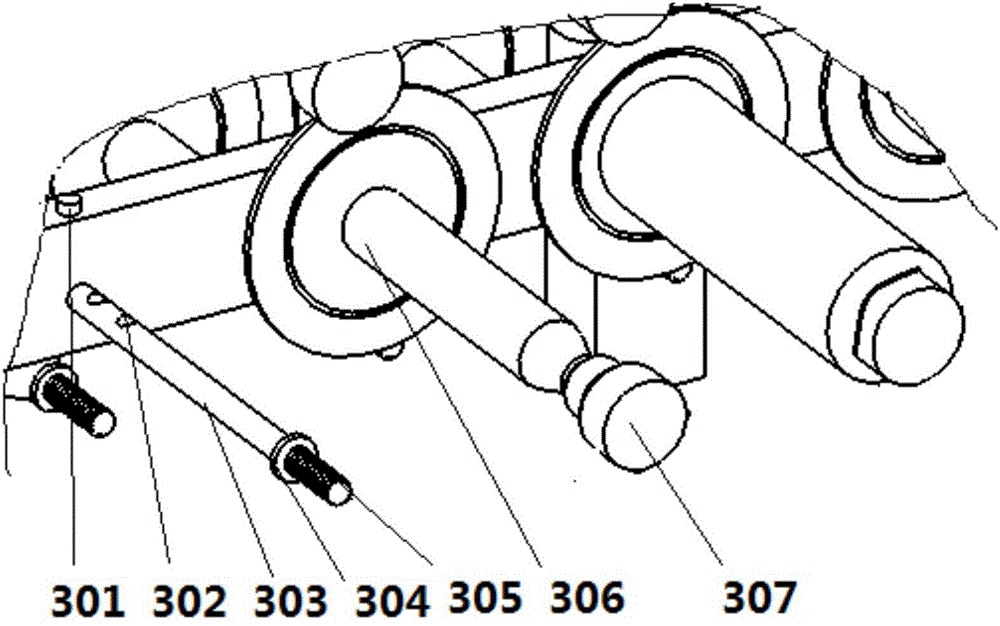

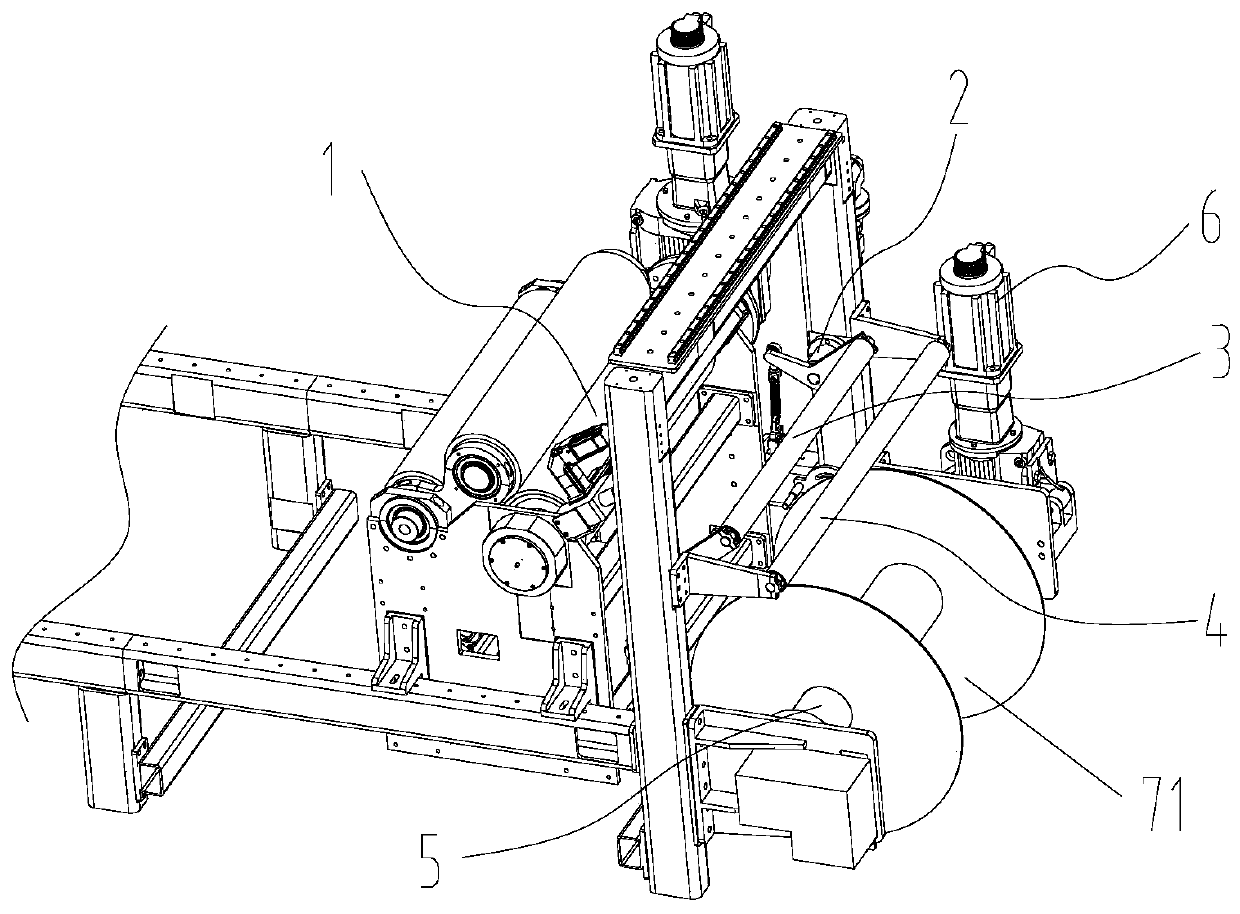

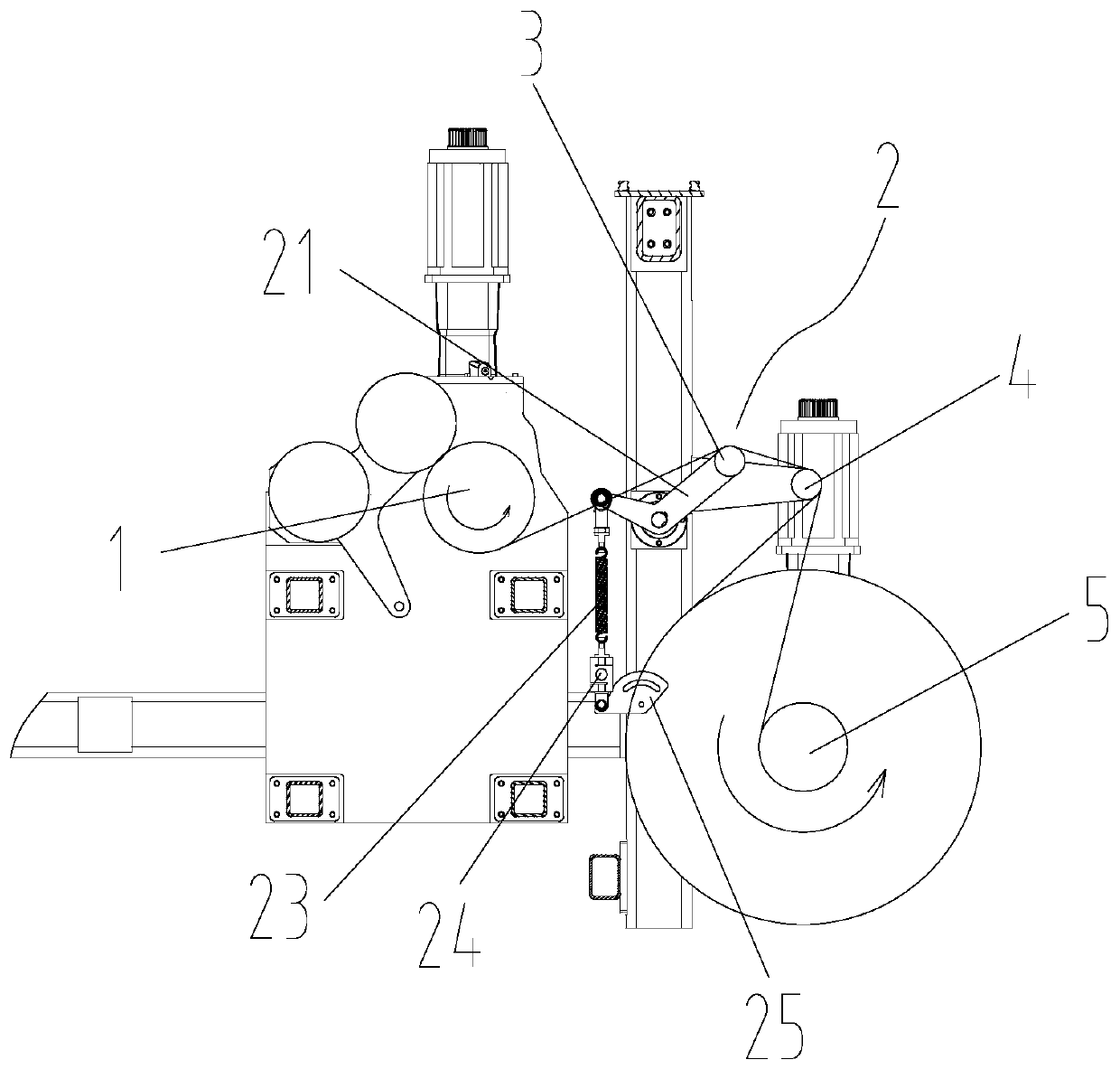

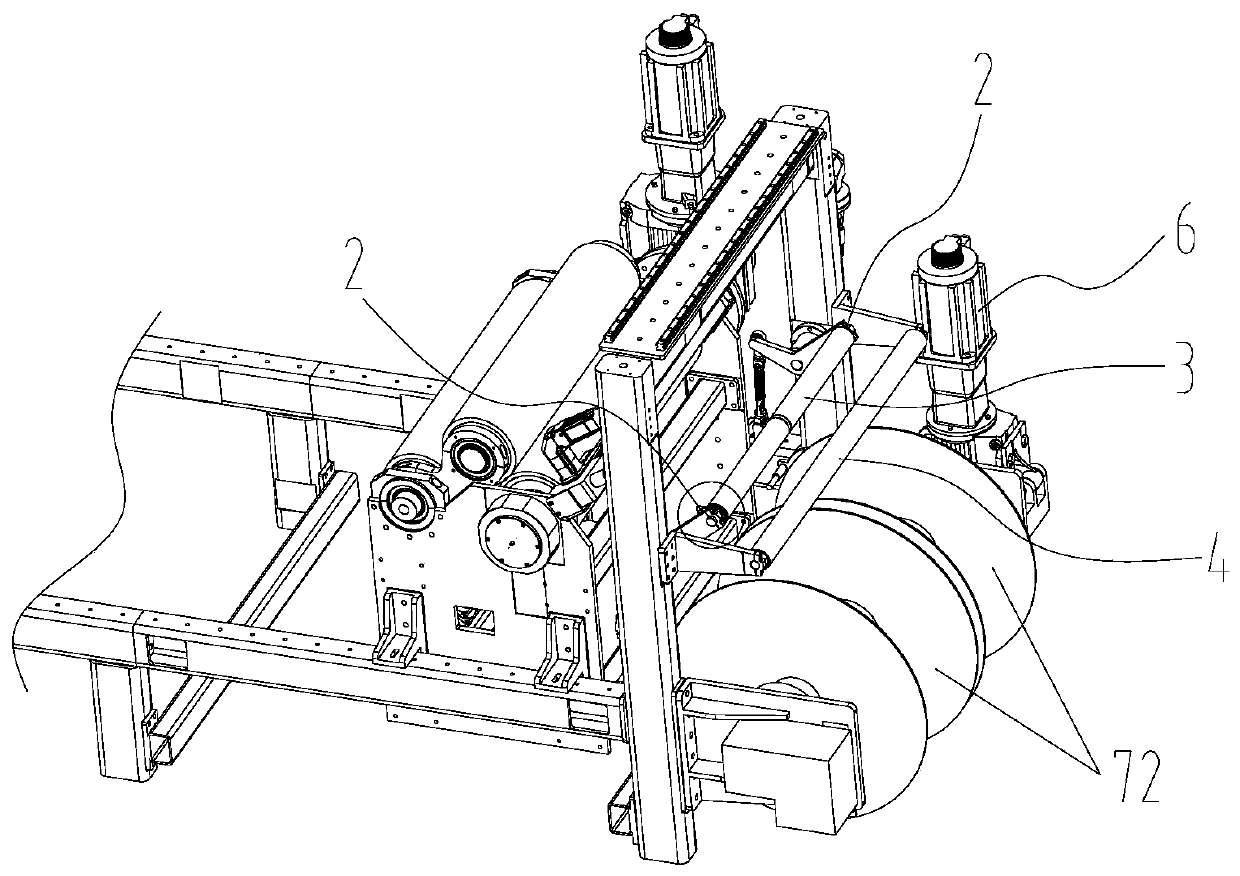

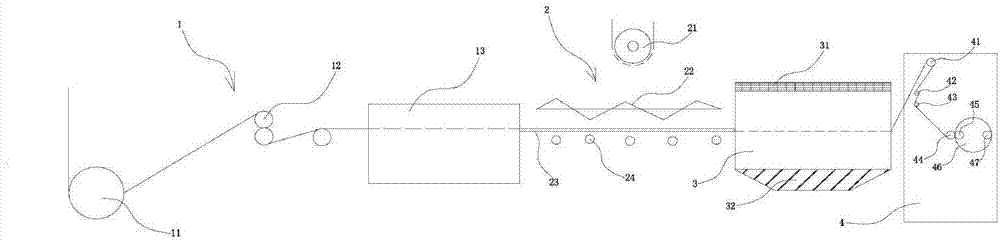

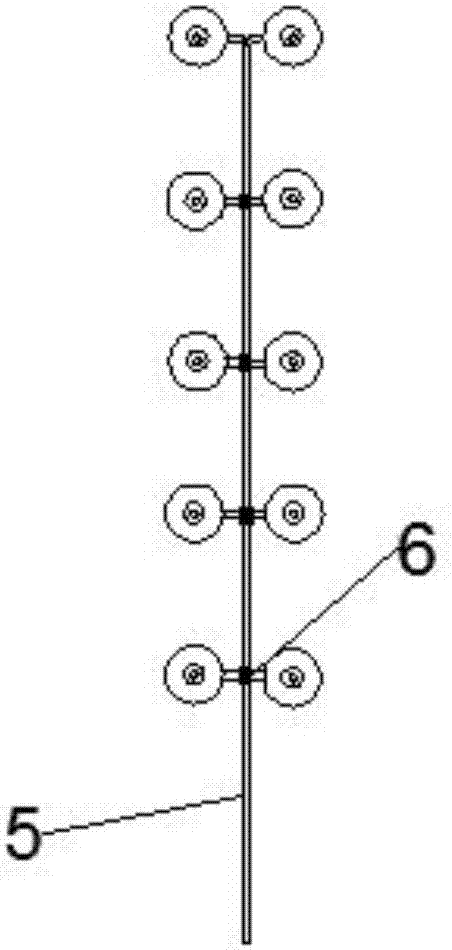

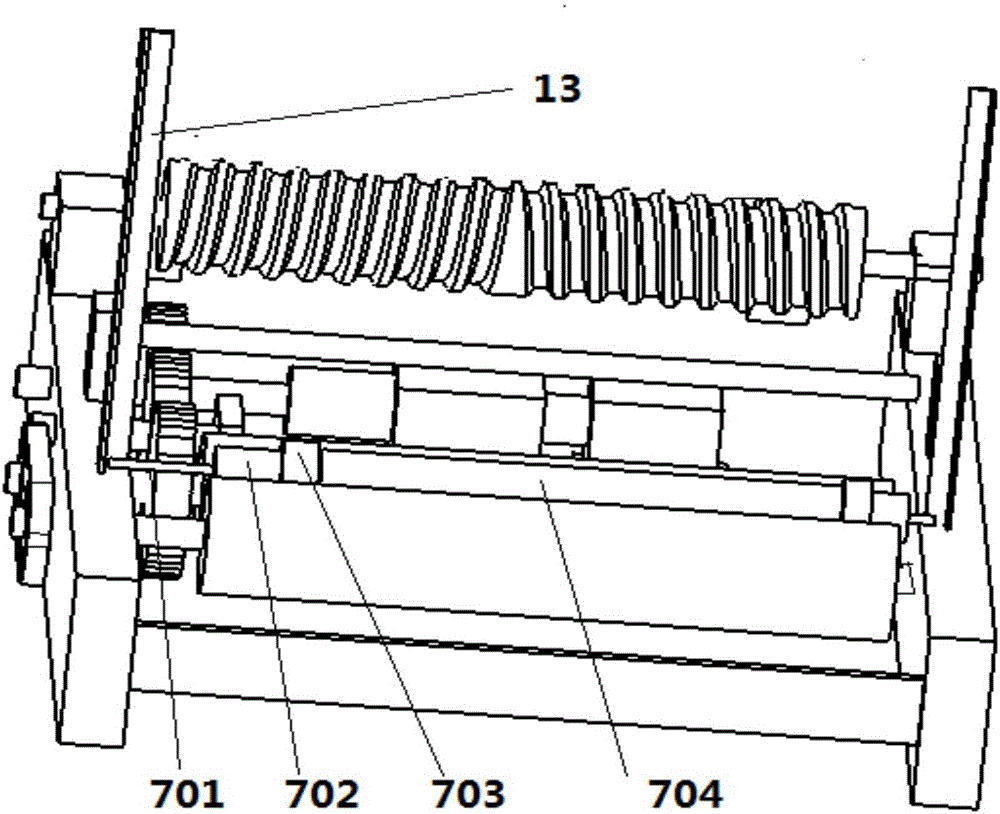

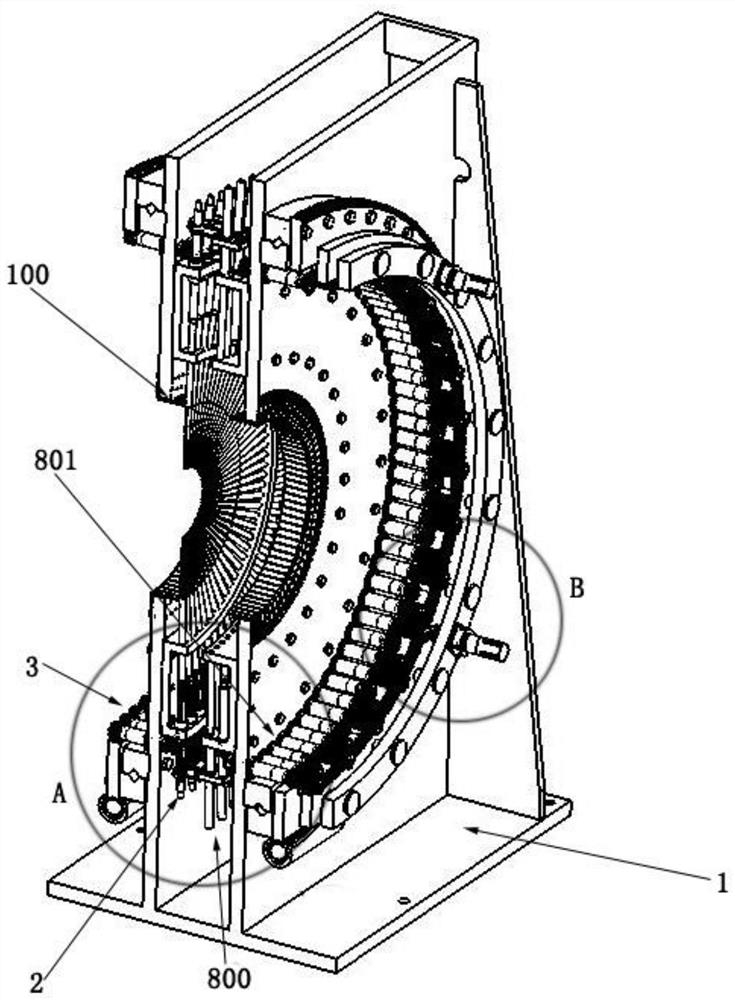

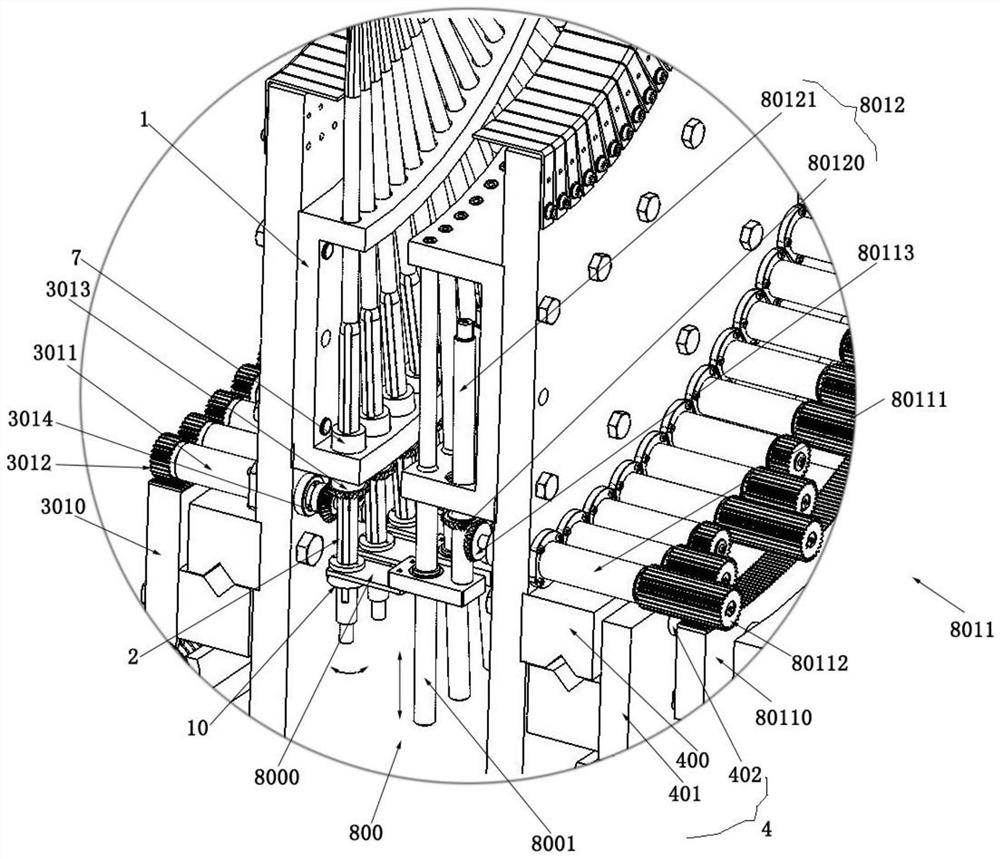

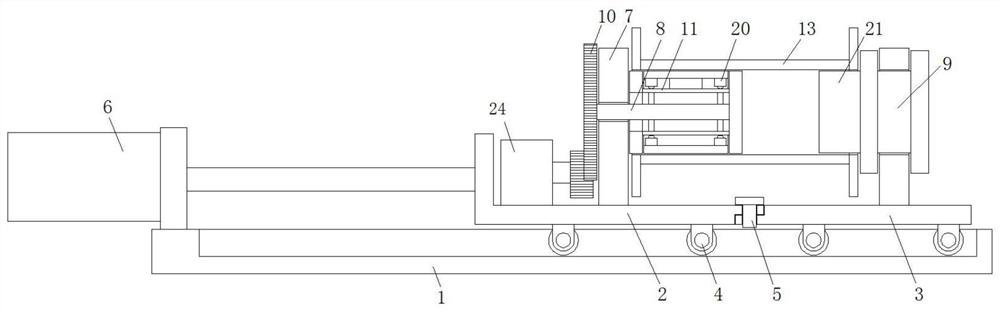

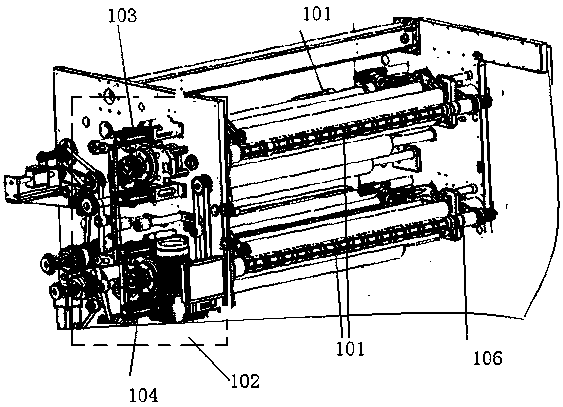

Semi-automatic winding machine and winding method for battery roll core

InactiveCN102368566AGuaranteed synchronicityQuality improvementFinal product manufactureElectrolyte accumulators manufactureWinding machineSemi automatic

The invention discloses a semi-automatic winding machine and a winding method for a battery roll core. The winding machine comprises a frame assembly, a pole piece feeding assembly and a winding pin assembly. The pole piece feeding assembly comprises two guide plates which are respectively used for placing passive and negative pole pieces. The winding pin assembly comprises a winding pin and a winding pin base. The frame assembly is provided with a synchronous conveying device for automatically conveying the passive and negative pole pieces on the guide plates to the winding pin. Due to the adoption of the technical scheme, the synchronous conveying device for automatically conveying the passive and negative pole pieces is additionally arranged, so that in the working process of the winding machine, the pole pieces which need to be wound only need to be fed into the guide plates and the passive and negative pole pieces are automatically and synchronously conveyed to the winding pin tobe wound under the mutual action of a driving roll and a guide roll, and thus, the synchronism of the passive and negative pole pieces in the conveying process is ensured, the cross infection betweenthe passive and negative pole pieces, which is generated in the operating process of an operator, can also be effectively prevented, the quality of the battery roll core is improved and the rejectionrate is reduced. Moreover, the production time can also be greatly saved and the labor intensity of the operator is also reduced.

Owner:铜陵市三圆机械制造有限公司

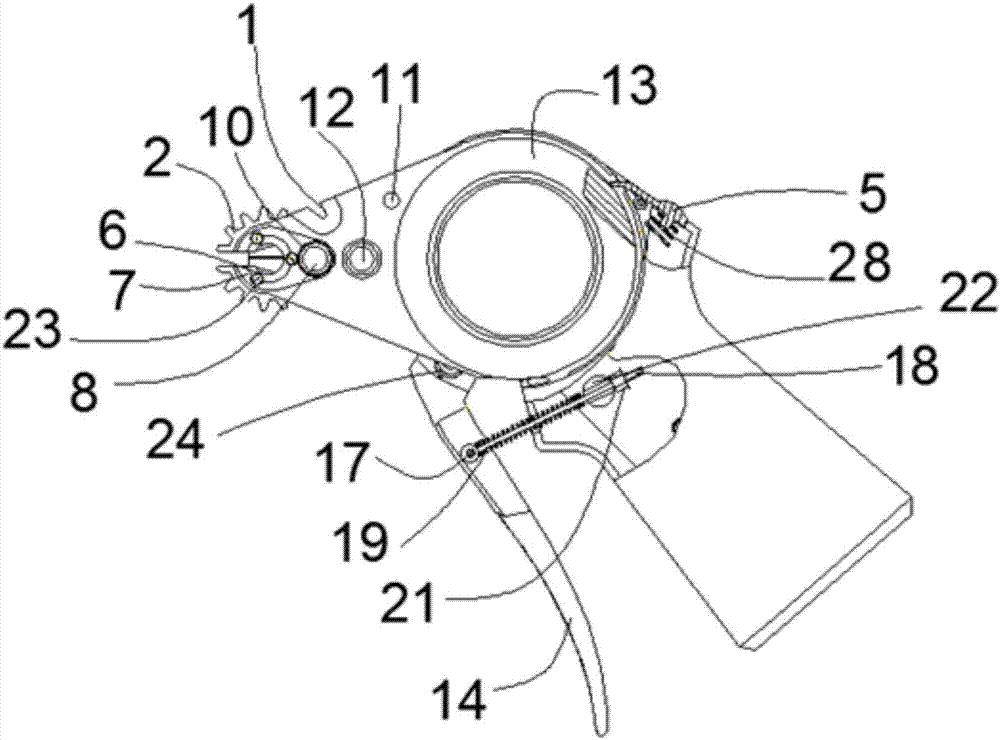

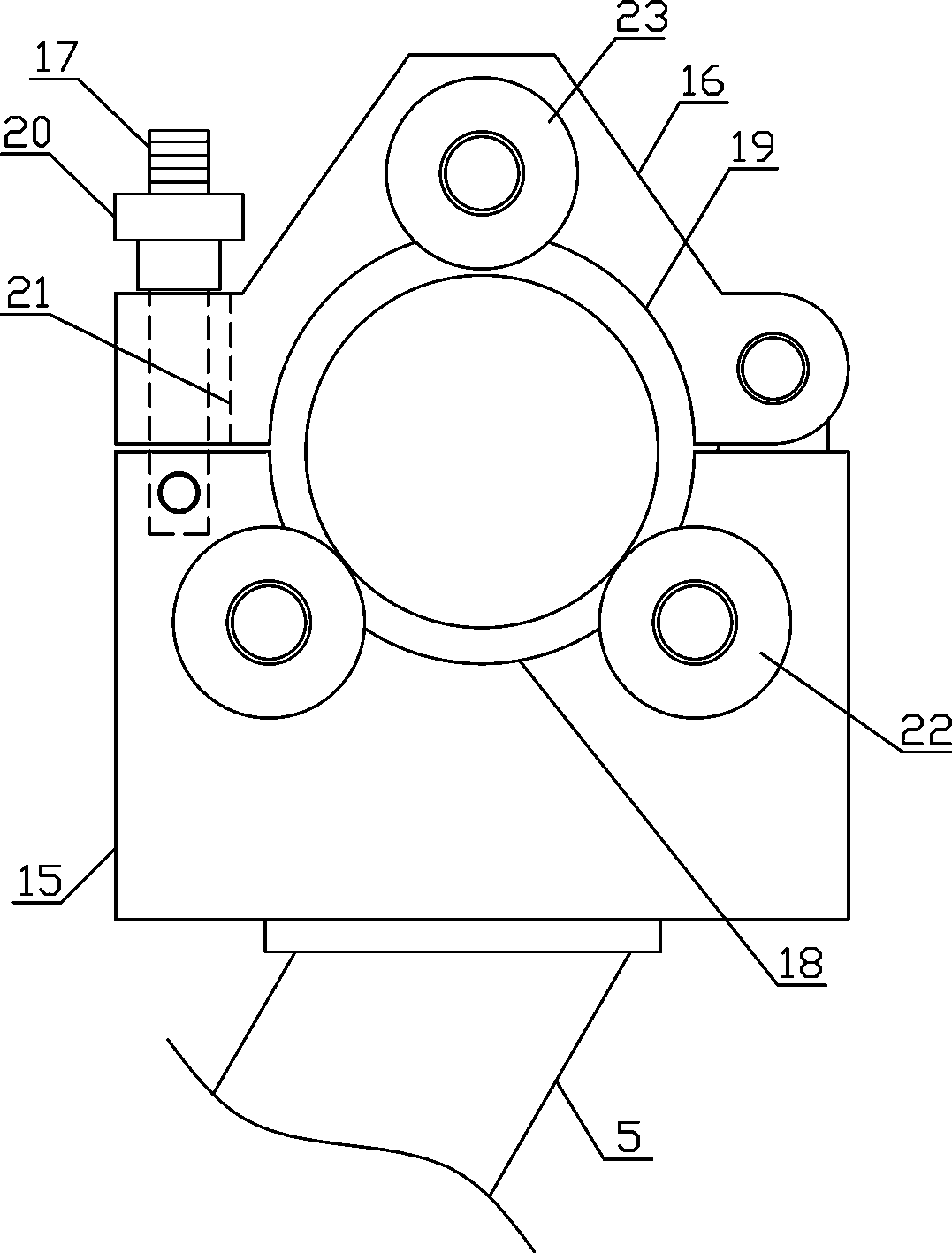

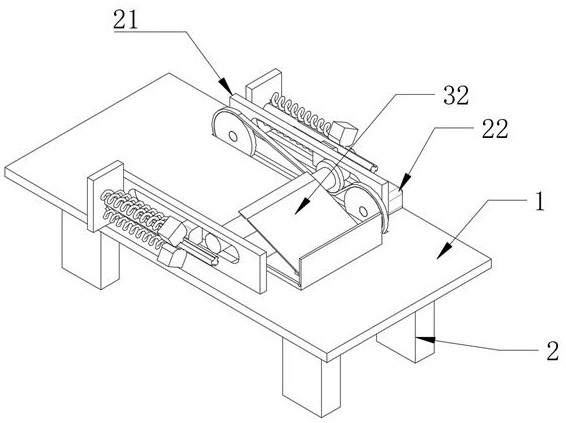

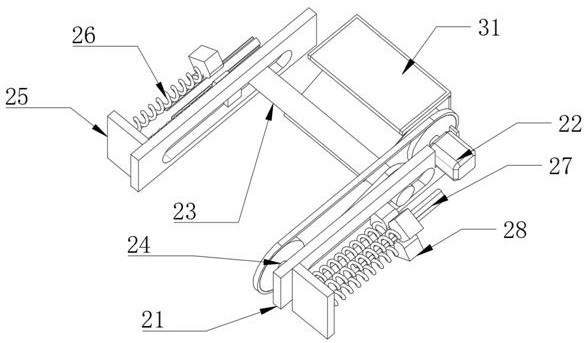

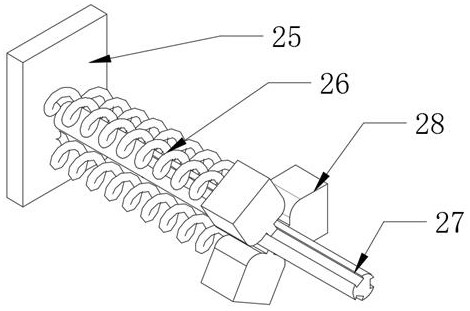

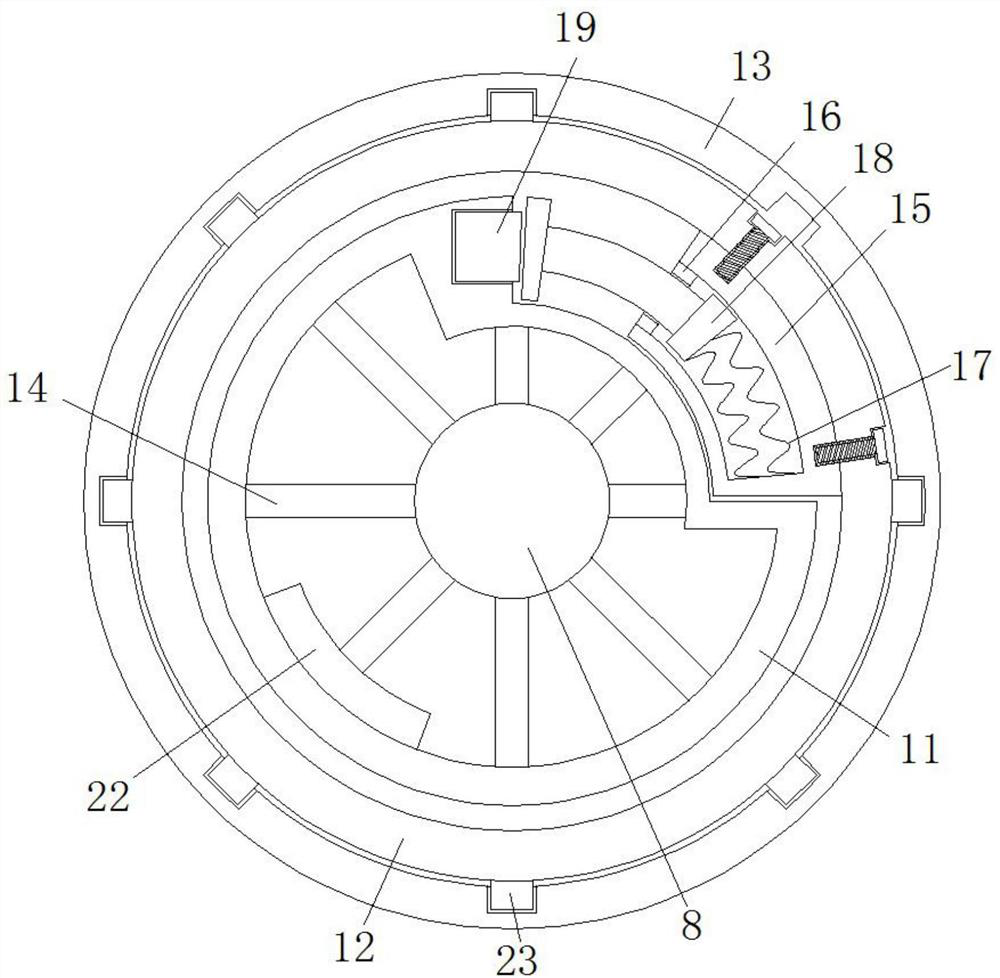

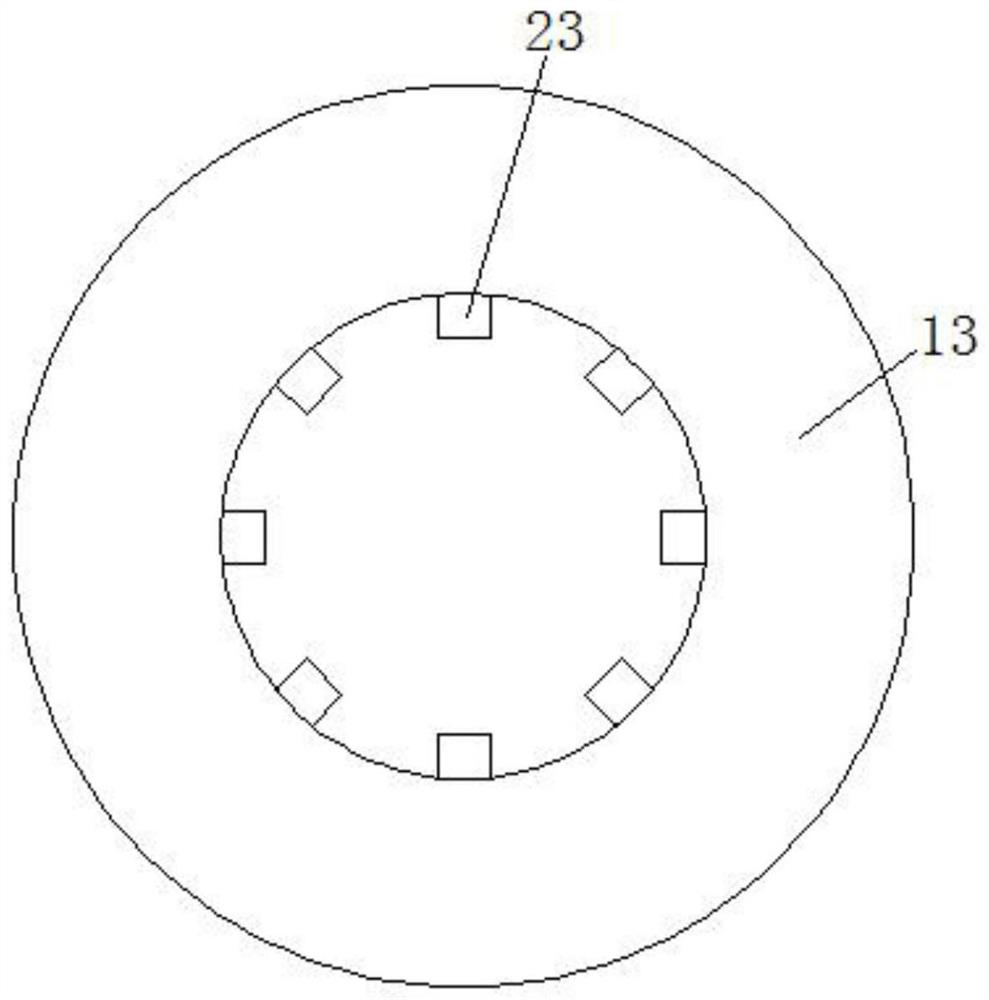

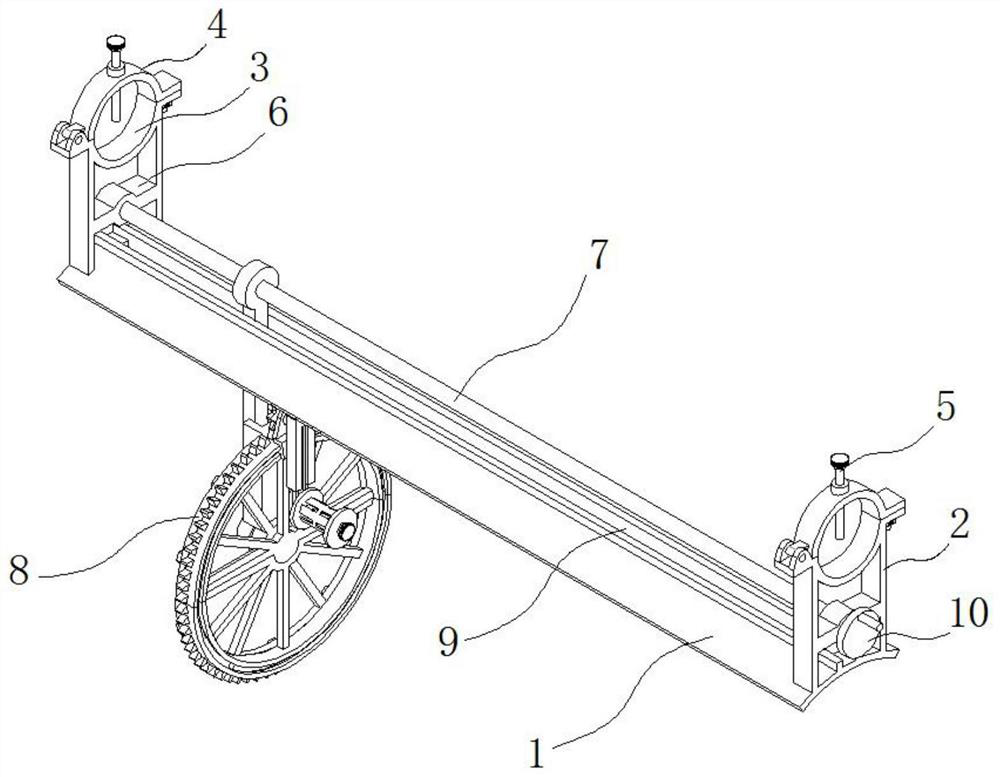

Electric wire connector

ActiveCN107317205AGuaranteed contact effectWind evenlyLine/current collector detailsStructural engineeringWire fixation

The invention discloses an electric wire connector that can reduce the labor intensity and has relatively good wiring quality. The electric wire connector comprises a wire connector main body, a wiring mechanism, a driving mechanism and an electric wire fixing device; the wiring mechanism comprises a wiring shaft rotatably arranged on the wire connector main body, and the driving mechanism is arranged on the wire connector main body and is in transmission connection with the wiring shaft; and the electric wire fixing device is arranged on the wire connector main body, and a clamping and fixing position of the electric wire fixing device corresponds to one end of the wiring shaft. The electric wire connector is used for connecting power lines, the thread residues are uniformly twined, the compactness is proper, and the lapping parts are sufficient, thereby being conducive to guaranteeing the contact performance of electric wires, meanwhile, the labor intensity is reduced, the wiring efficiency is improved, and moreover, the quality and efficiency of twining insulating tapes are improved.

Owner:PANZHIHUA UNIV

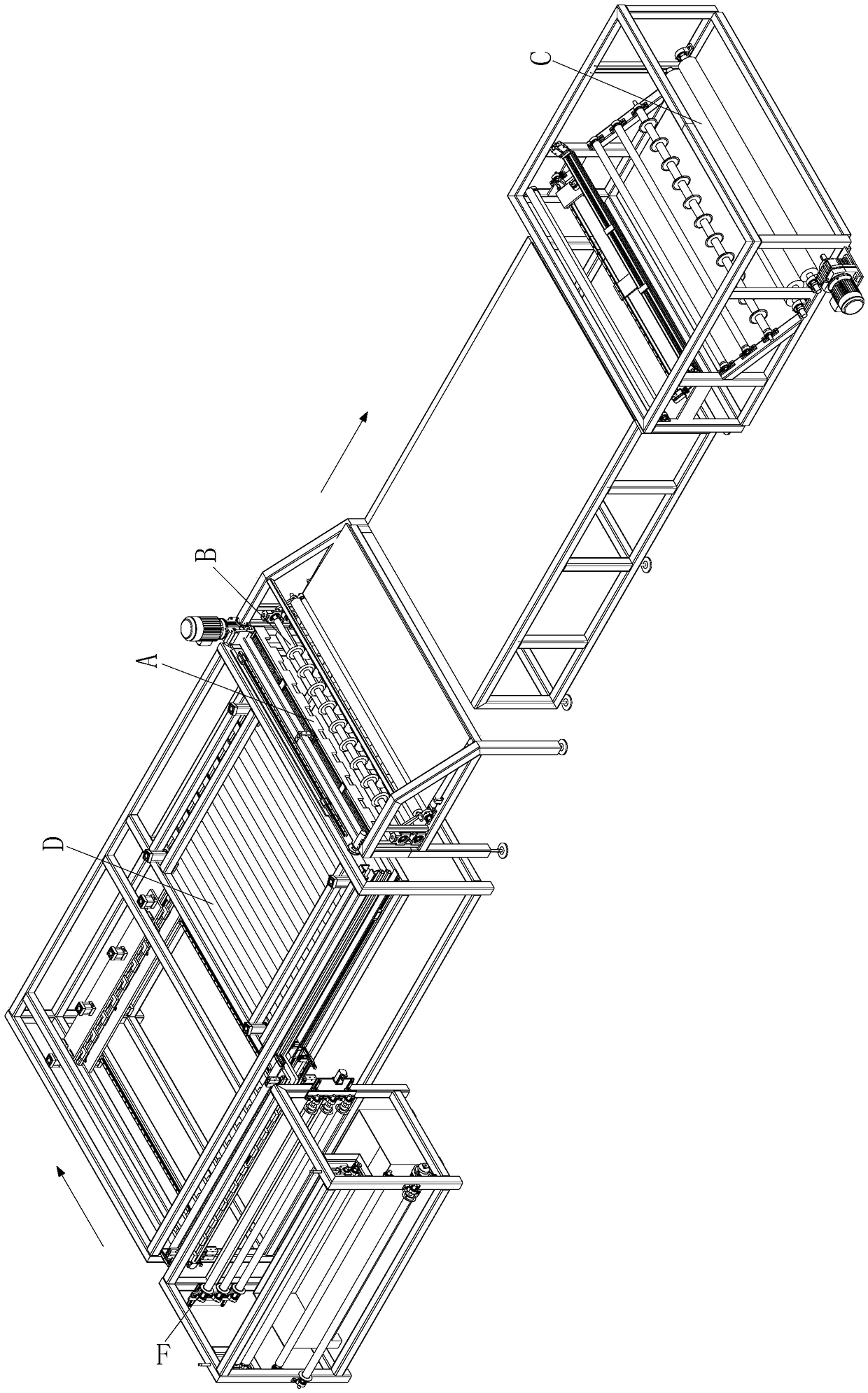

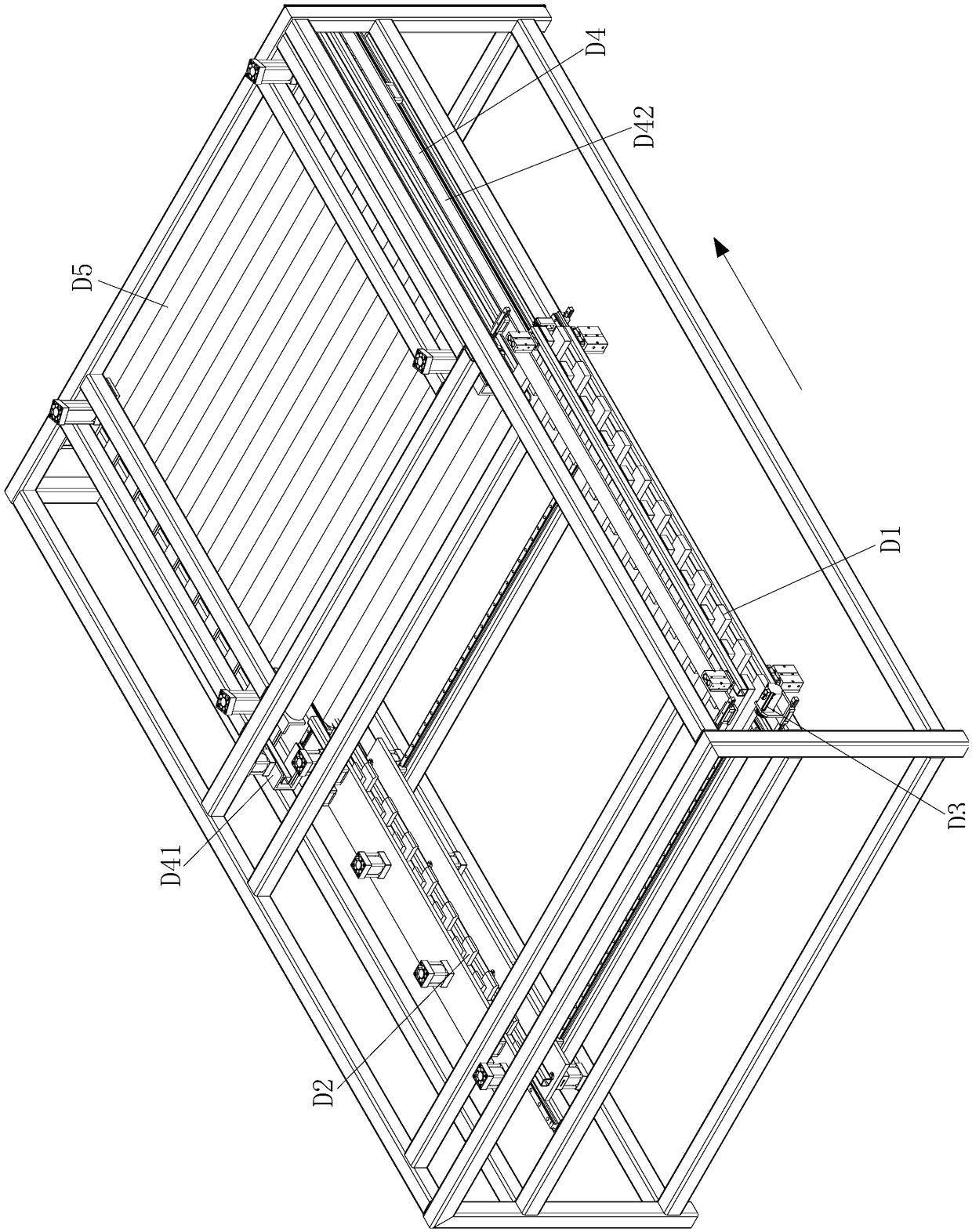

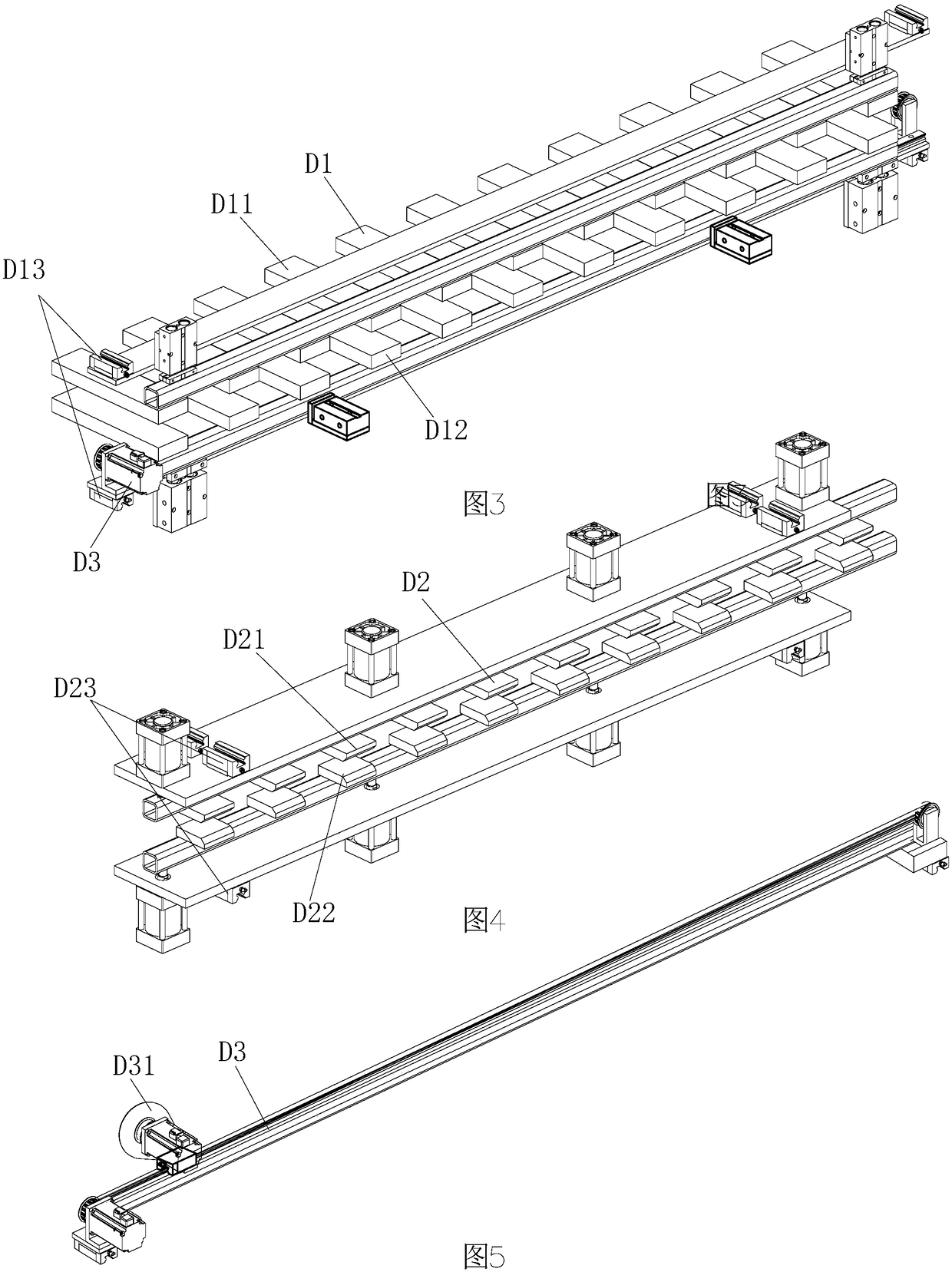

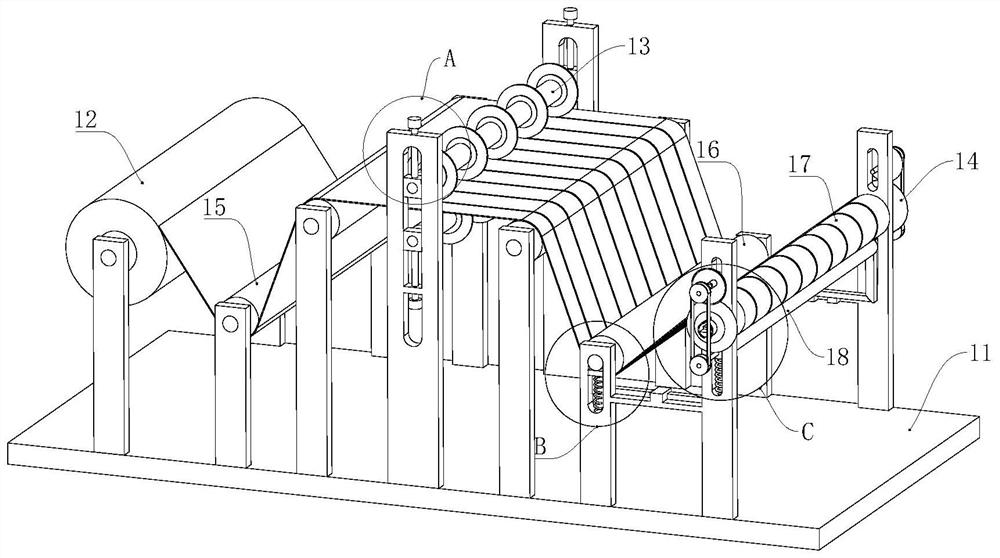

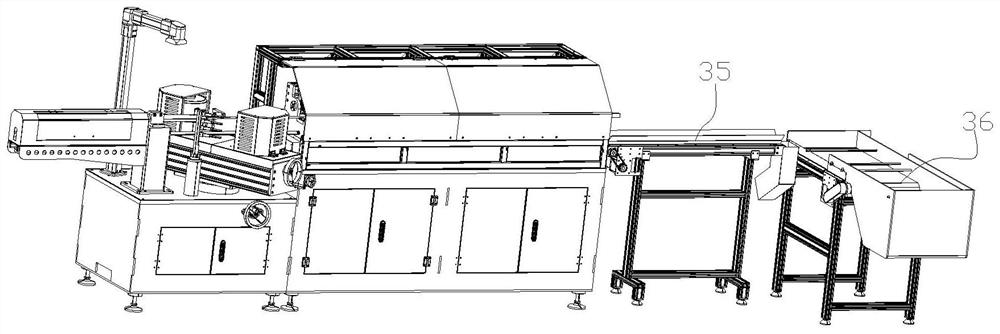

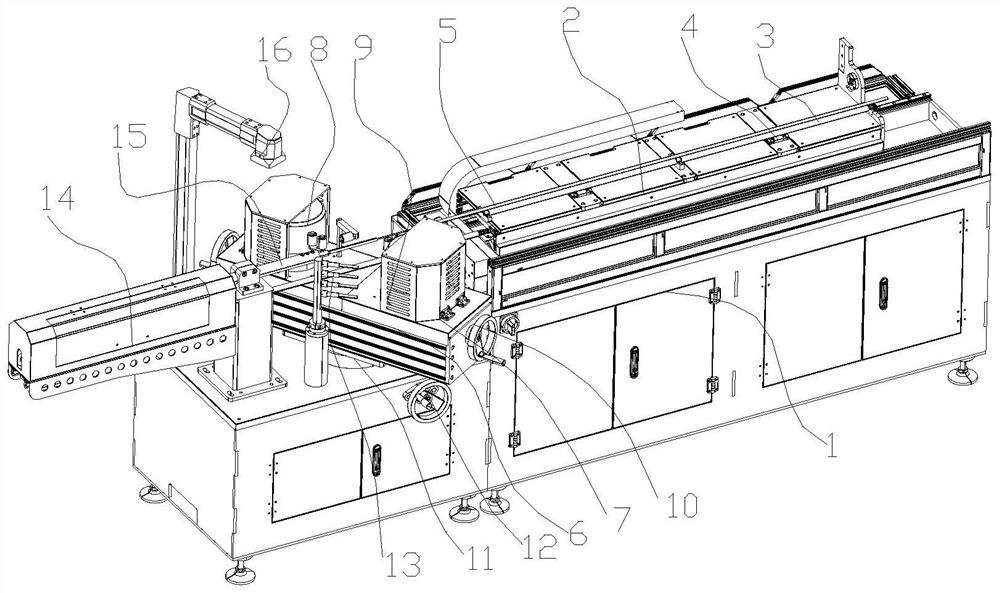

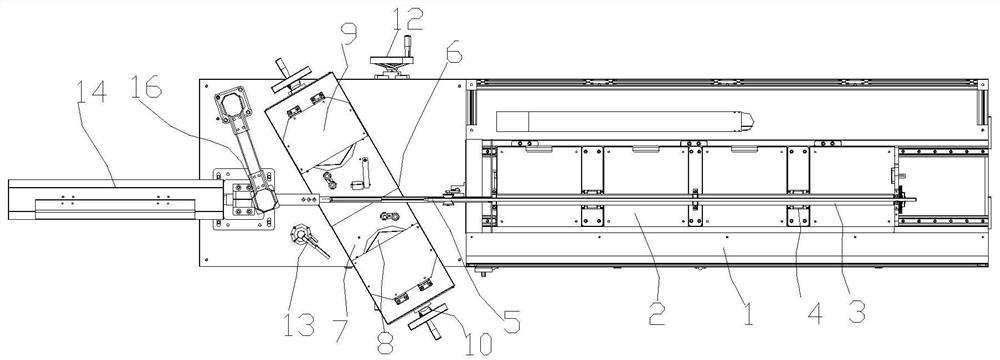

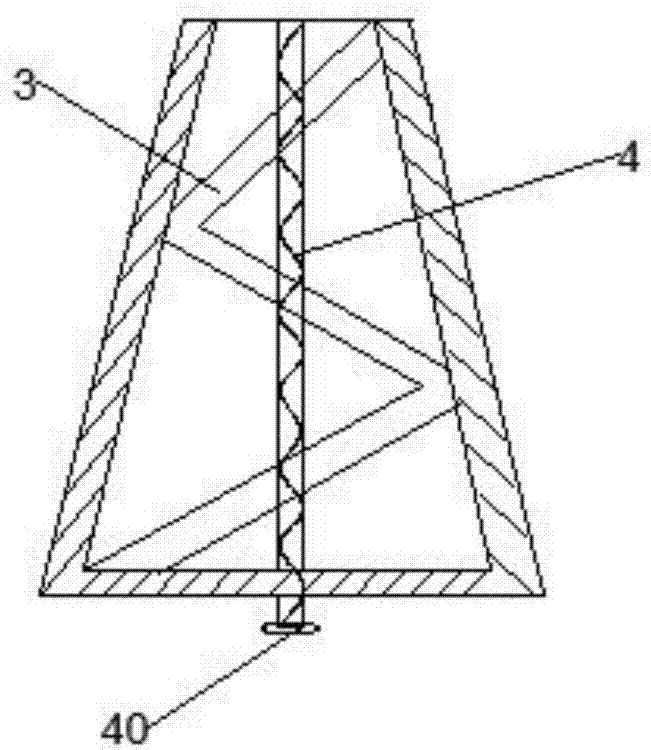

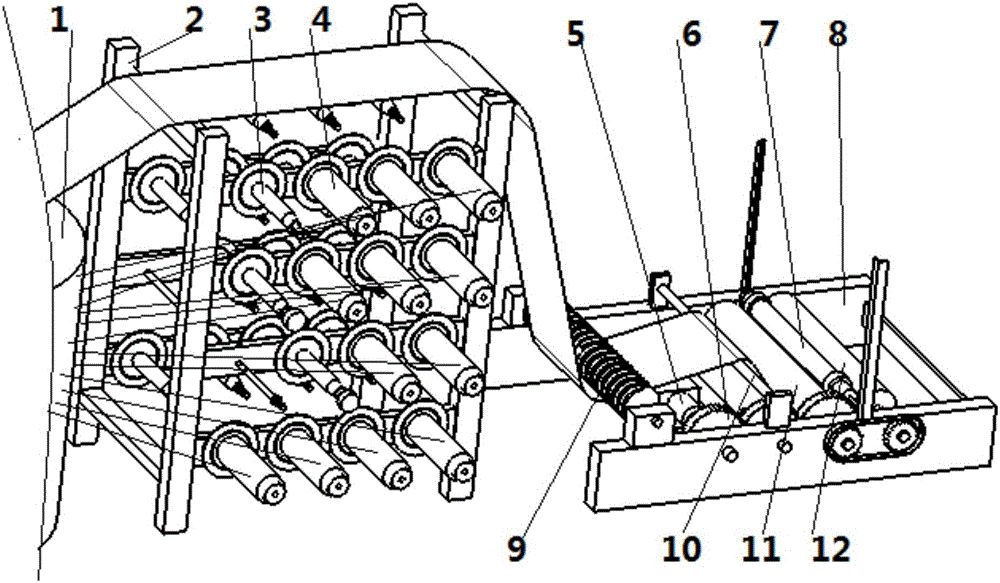

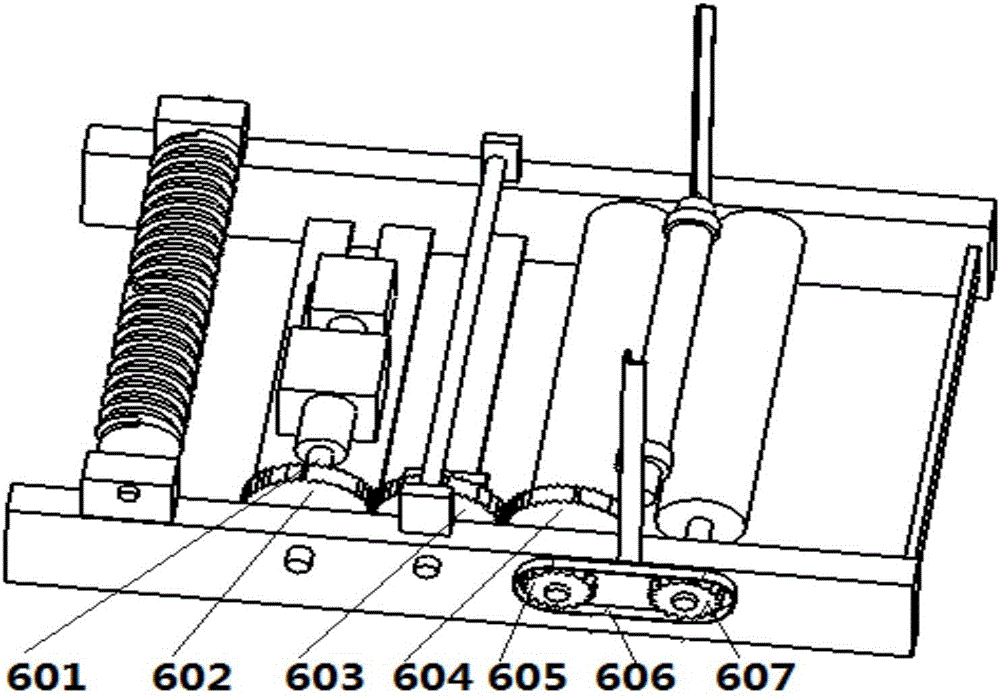

Equipment and process for processing bamboo split roll

InactiveCN109397437ANo disconnectionNo degumming will occurCane mechanical workingGlue gunsEngineeringMechanical engineering

The invention relates to the processing technology of bamboo split rolls, in particular to equipment and a process for processing a bamboo split roll, and specially relates to the processing field ofbamboo split rolls. The equipment comprises a feeding device for conveying and cutting off a bamboo split curtain along a braided wire direction and an axial feeding device for conveying bamboo splitsheets formed by cutting off the bamboo split curtain along the length direction of the bamboo split. The conveying directions of the feeding device and the axial feeding device are mutually perpendicular. The equipment also comprises an adhering device for adhering front and back bamboo split sheets end to end in the length direction of the bamboo split, a slitting device for slitting the bamboosplit curtain formed by adhering the bamboo split sheets in the length direction of the bamboo split curtain and a rolling device for rolling the slit bamboo split long curtains. The feeding device, the axial feeding device, the adhering device, the slitting device and the rolling device are arranged successively. The bamboo split rolls do not shift if being conveyed, split clash during slitting is avoided, distorsion is avoided during rolling, and no gaps are available in the middle of the bamboo split roll.

Owner:ZHEJIANG GUANGXIN BAMBOO BASED MATERIALS CO LTD

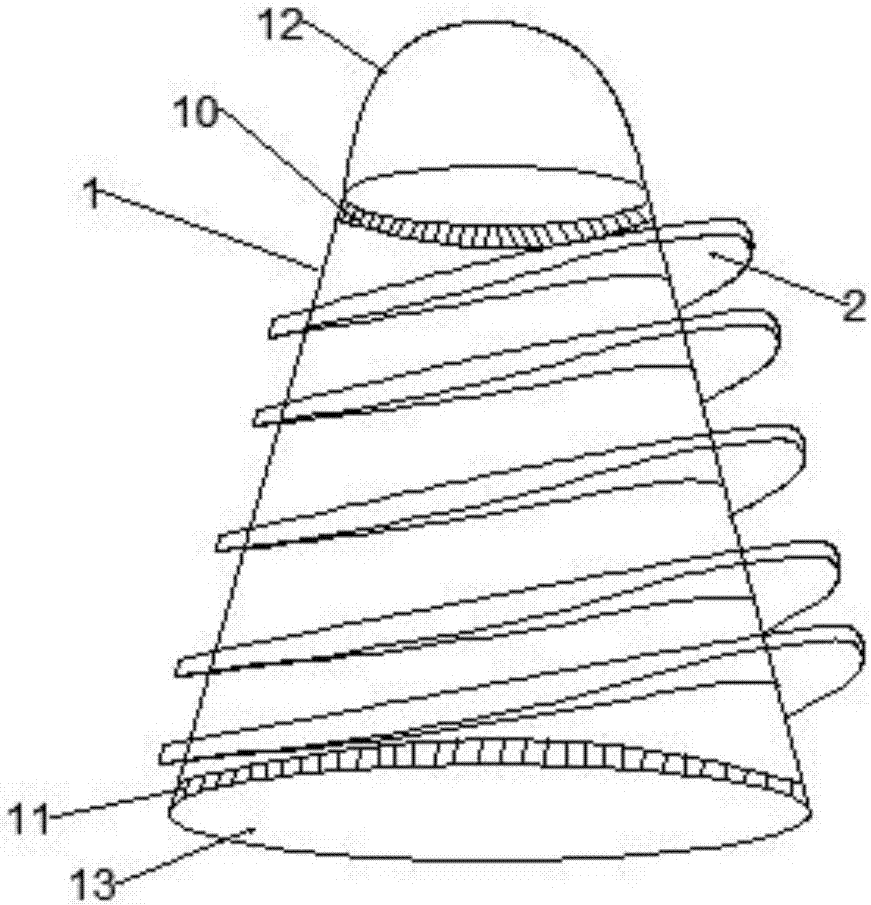

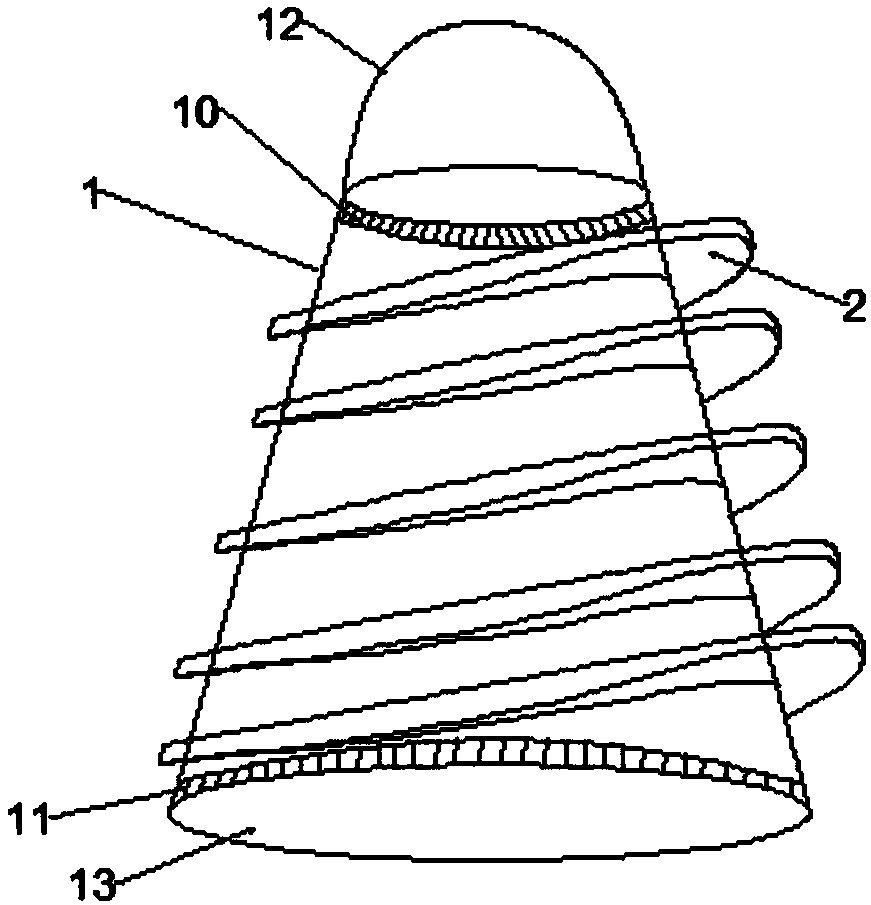

Soft cone spooling process applied to dyeing of cones of viscose filament yarns

The invention discloses a soft cone spooling process applied to dyeing of cones of viscose filament yarns. Viscose filament yarns are divided into an inner viscose filament yarn layer, a middle viscose filament yarn layer and an outer viscose filament yarn layer to be spooled on a soft spooling tube to form a soft cone by a soft cone spooler. The end face of the soft cone is inclined at 50 DEG-90 DEG. In spooling, the intersection angle of each two viscose filament yarns is 6 DEG-8 DEG. A spooling arm on the soft cone spooler is perpendicular to a yarn guide roller under the pressure of 150-800g, and the density of the viscose filament yarns on the formed soft cone is 0.3-0.5g / cm<3>. According to the technical scheme and by optimizing and modifying the soft cone spooling process and parameters thereof, the moderate density of the soft cone formed by spooling can be guaranteed, the soft cone is fine in uniformity, and forming of the soft cone is stable.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

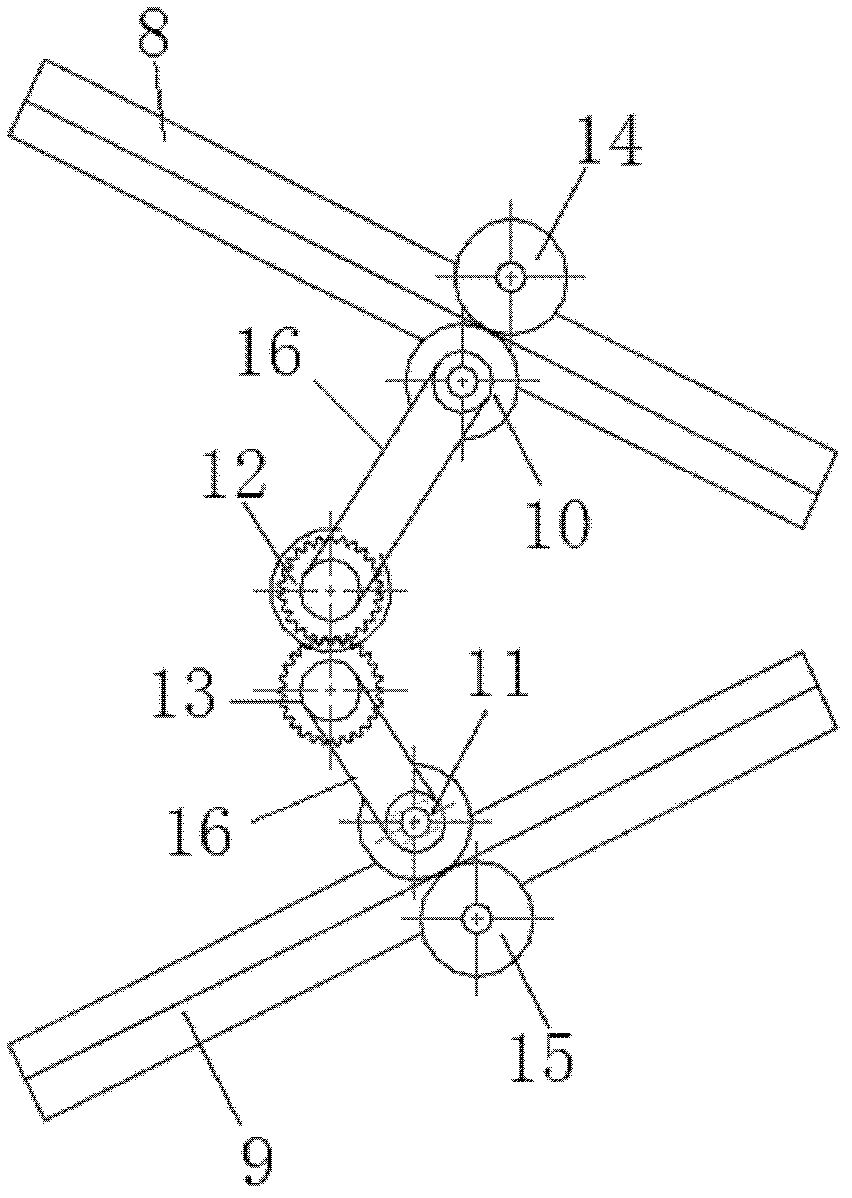

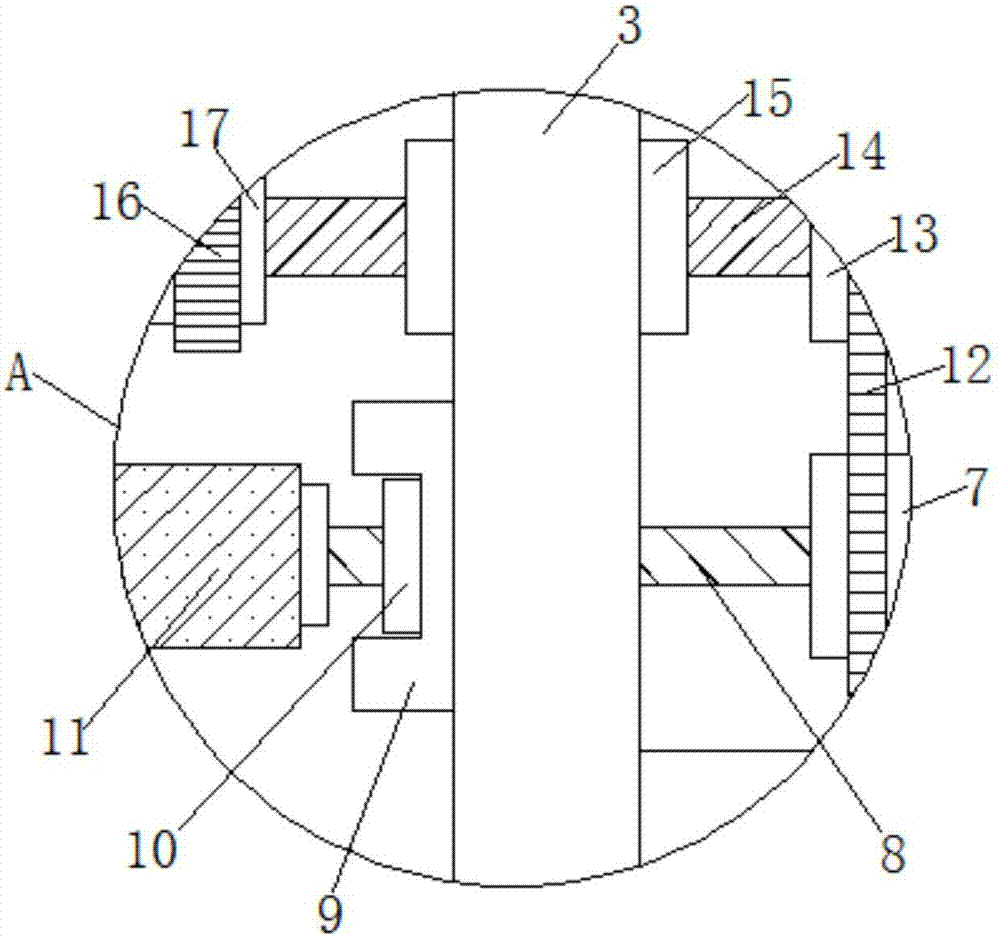

Wool top reciprocated continuous rolling mechanism

InactiveCN108792785AReasonable structural designEfficient and stable rotationFilament handlingMechanical equipmentEngineering

The invention discloses a wool top reciprocated continuous rolling mechanism, and belongs to the field of textile processing mechanical equipment. An upper rolling pull roller and a lower rolling pullroller of the mechanism are sequentially, horizontally and rotationally connected to a rotary roller support in the inclined direction from top to bottom, the output end of a rolling motor is in transmission connection with the upper rolling pull roller through an upper pull roller belt, the output end of the rolling motor is in transmission connection with the lower rolling pull roller through alower pull roller belt, the lower side of the rolling support is hinged to a rotating support, roller clamping mechanisms are symmetrically arranged on the two sides of the upper portion of the rolling support, the output end of a rolling air cylinder is vertically and rotationally connected with a rolling pressing wheel, a feeding rotary roller is horizontally and rotationally connected to one side of the upper portion of the feeding support, and a wool top guide mechanism is arranged on the upper side of the fixed support in an inclined manner. The wool top reciprocated continuous rolling mechanism is reasonable in structural design, wool tops can be efficiently and conveniently conveyed and rolled continuously and stably, the wool top rolling efficiency and quality are improved, and needs for production are met.

Owner:盛奇石

Textile rolling device with automatic leveling and cleaning functions

InactiveCN107381150AWith self-levelingWith cleaning functionWebs handlingEngineeringAutomatic testing

The invention discloses a textile winding device with automatic leveling and cleaning functions, which comprises a support platform and a top plate, both sides of the top of the support platform are fixedly connected with support frames, and the tops of the two support frames are respectively connected to the two sides of the bottom of the top plate Fixed connection, the top of the top plate is fixedly connected with five return springs, the tops of the five return springs are fixedly connected with buffer seats, and the tops of the five buffer seats are fixedly connected with the bottom of the buffer table, the top of the buffer table, etc. There are five buffer columns fixedly connected at a distance, and brushes are fixedly connected to the tops of the five buffer columns. The textile winding device with automatic leveling and cleaning functions, by setting the cloth guide roller and the cloth take-up roller, the user can put the textile to be wound on the cloth guide roller, when the cloth guide roller and the cloth take-up roller rotate The textile will be rewinded. During the rewinding process, the outer surface of the textile can be automatically cleaned through the combined use of the buffer table, buffer column and brush.

Owner:梅明会

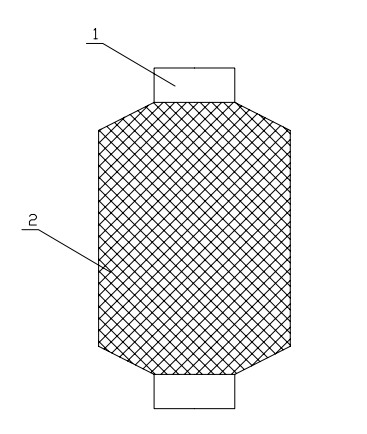

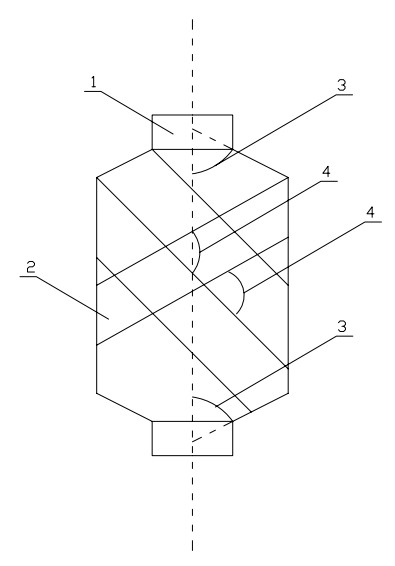

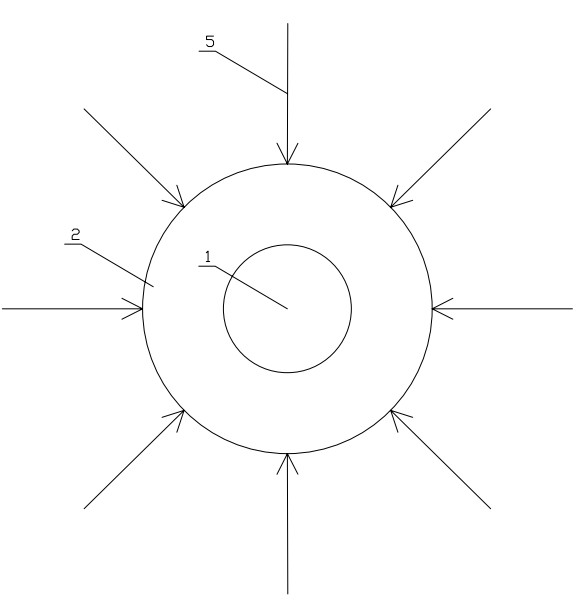

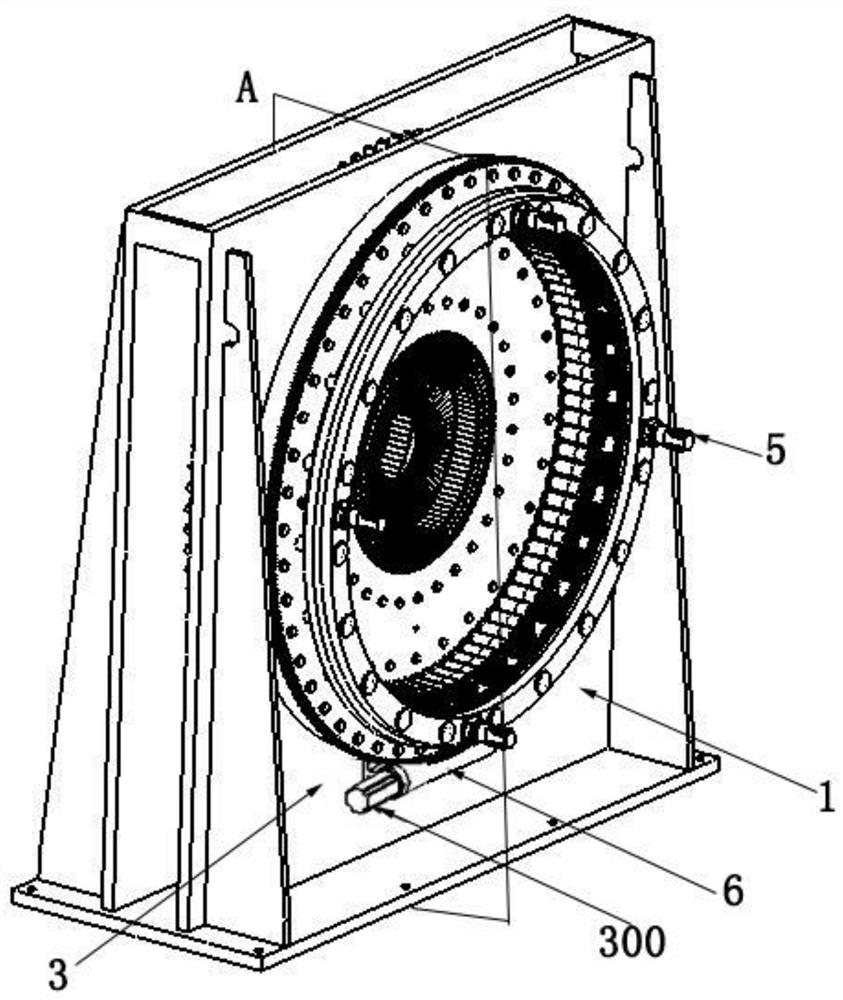

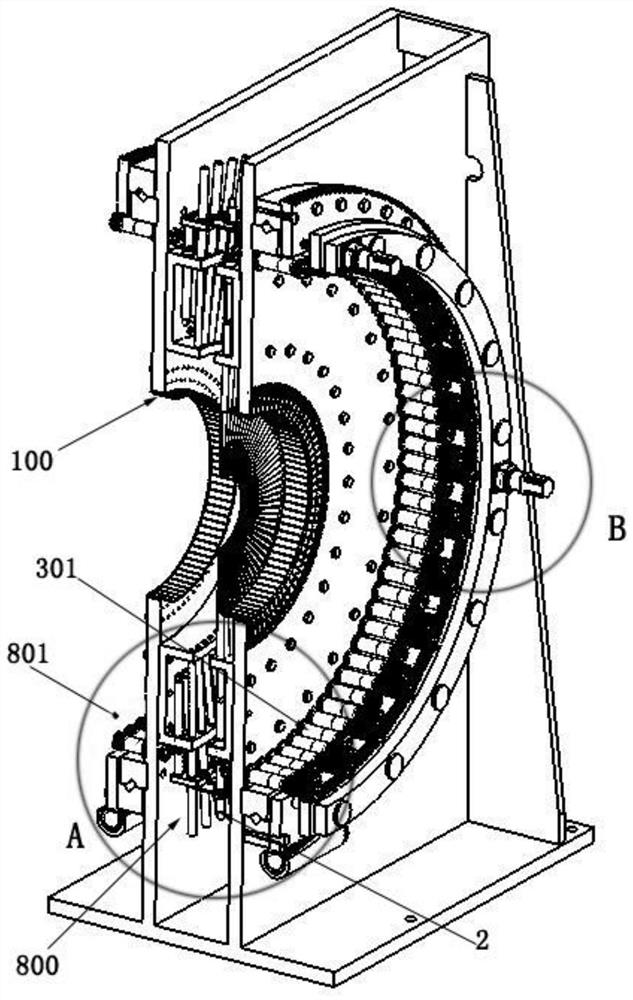

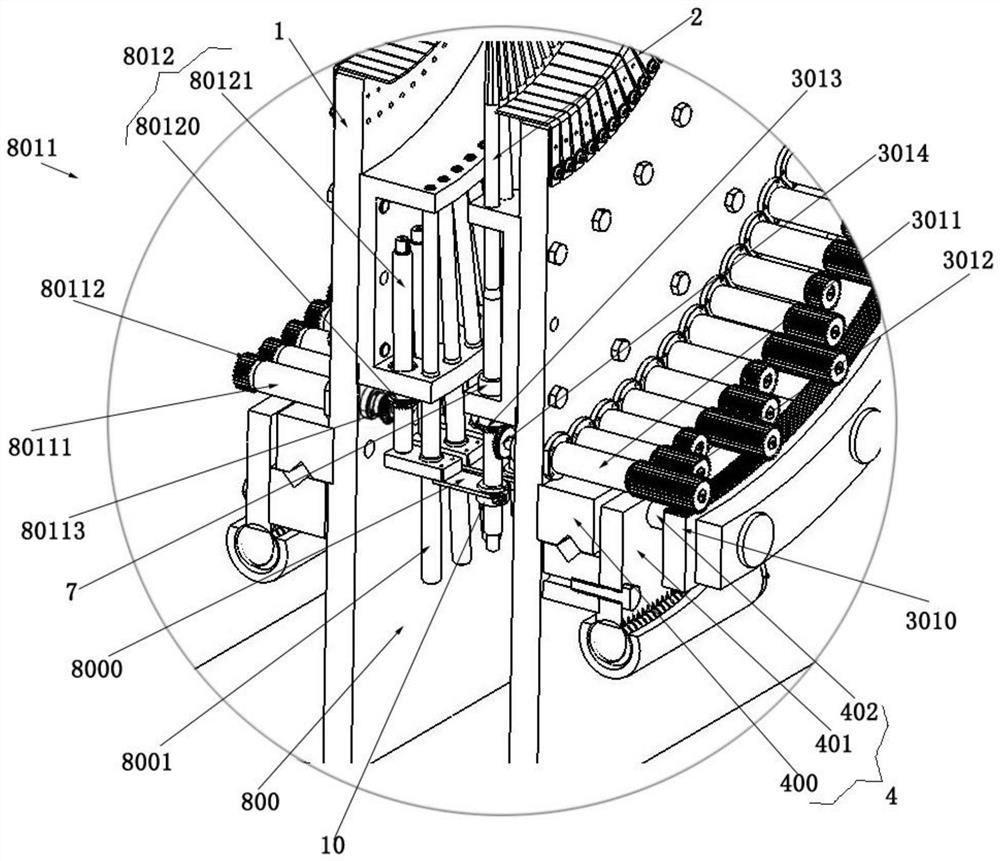

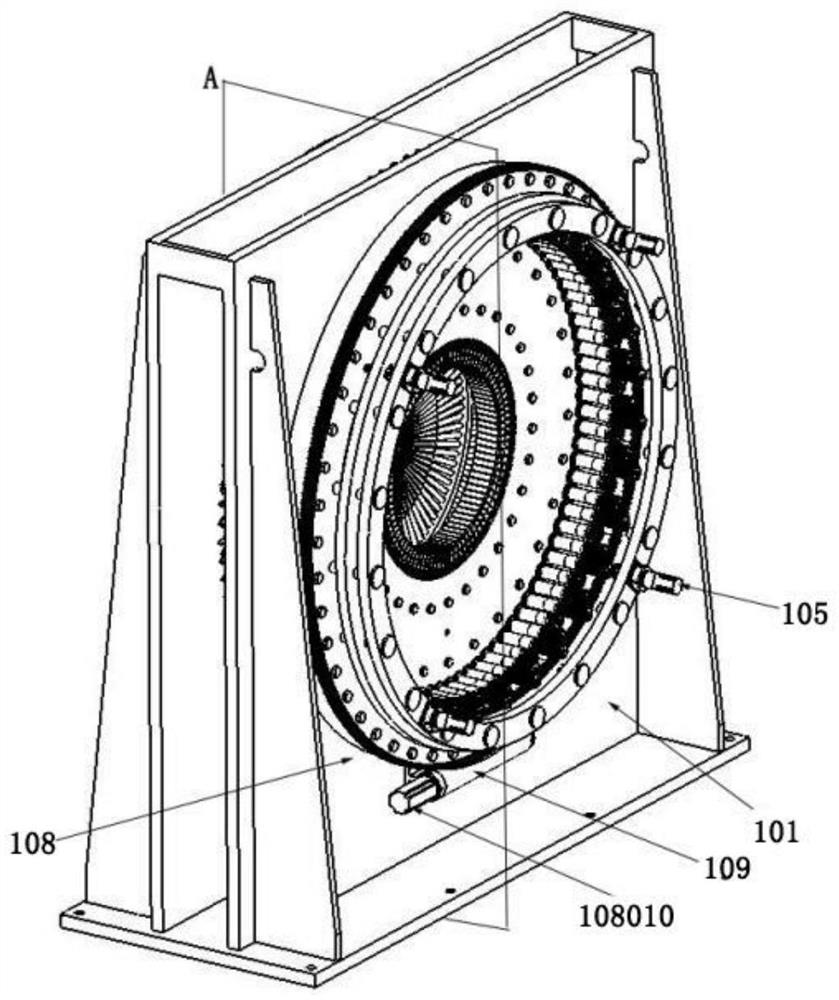

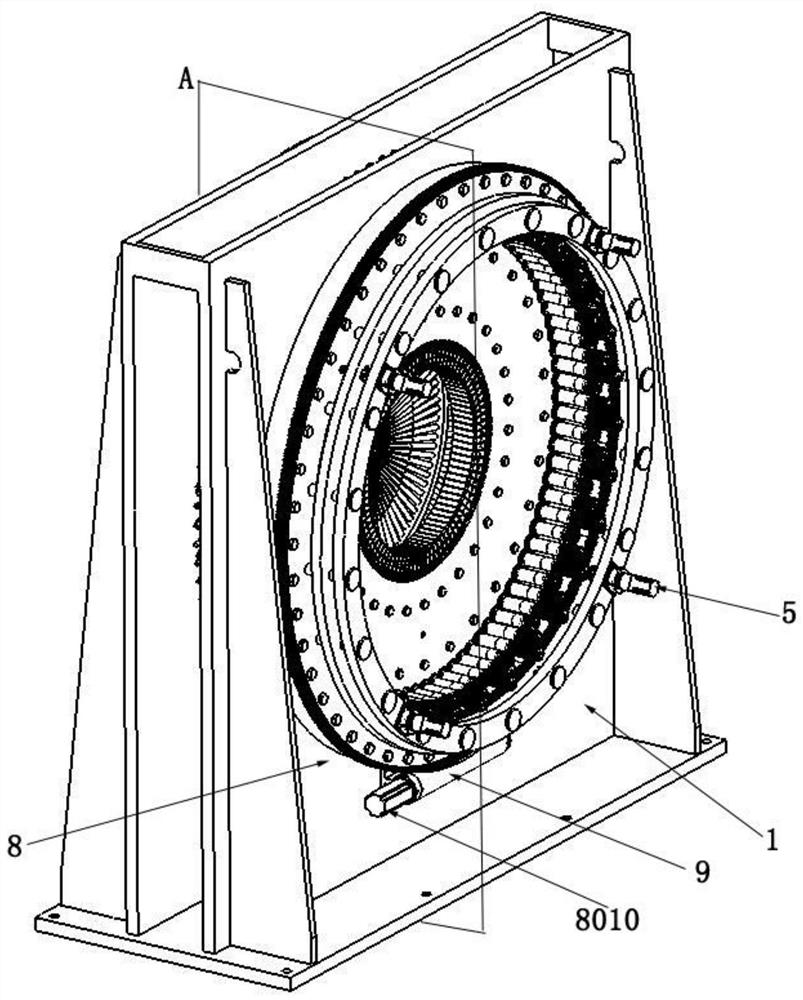

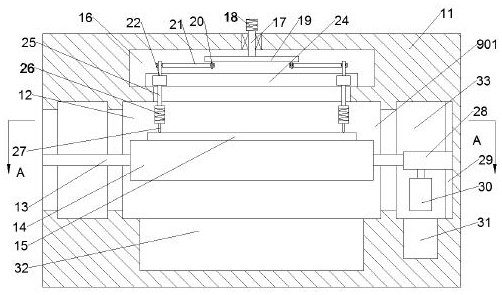

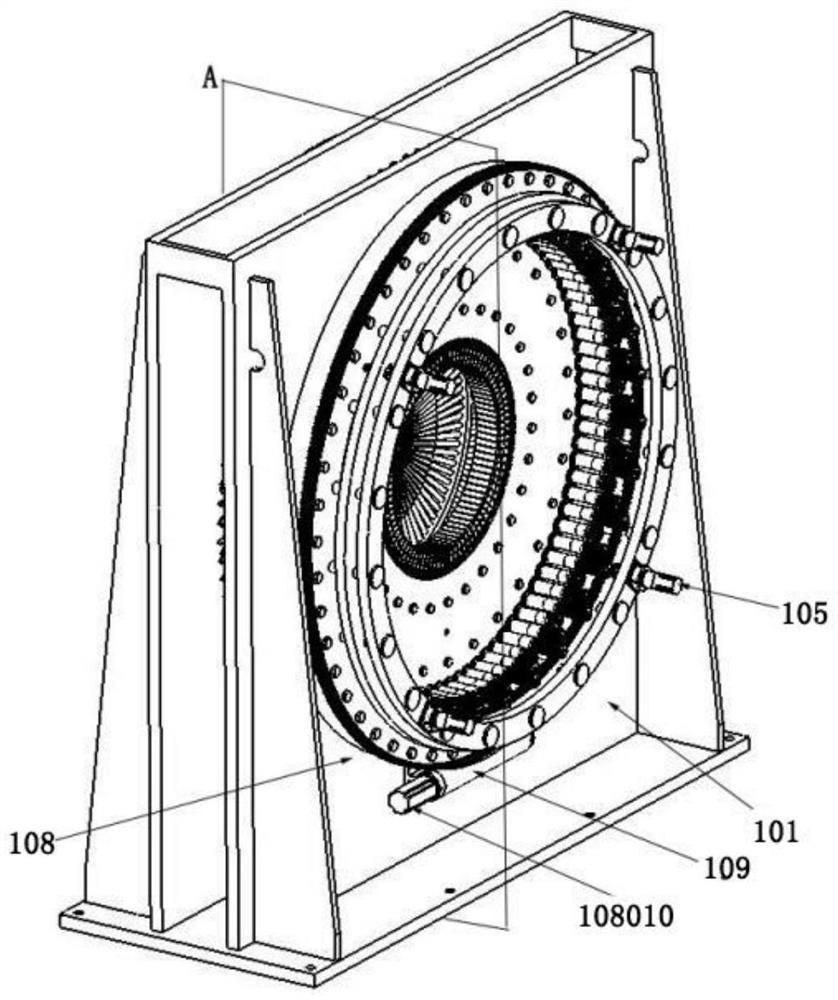

Adjustable multi-bundle fiber spiral winding device

ActiveCN113371535AImprove fitImprove the winding effectFilament handlingDomestic articlesPhysicsGuide wires

The invention belongs to the technical field of fiber winding devices, and particularly relates to an adjustable multi-bundle fiber spiral winding device which comprises a frame body and a plurality of fiber guide heads. A through hole is formed in the frame body, the fiber guide heads are annularly distributed along the center of the through hole and are in sliding connection with the frame body, and fibers can extend out of each fiber guide head; and a telescopic mechanism is arranged on the frame body, and the fiber guide heads are driven to stretch out and draw back through the telescopic mechanism. The fiber guide heads are annularly distributed along the center of the through hole and are all in sliding connection with the frame body, the fibers can extend out of each fiber guide head, and the led-out fibers can be uniformly distributed on the outer surface of a pressure container in a spiral shape; and the telescopic mechanism drives the fiber guide heads to stretch out and draw back, the fiber guide heads can control the wire guide heads to stretch out and draw back according to changes of the appearance of the pressure container, and therefore the fibers can be better attached to the pressure container, and the winding effect is improved.

Owner:TAIYUAN UNIV OF TECH

Winder for cloth weaving machine

InactiveCN106081716ANeatly rolledLow failure rateLoomsFilament handlingHigh volume manufacturingEngineering

The invention provides a winder for a cloth weaving machine. The winder comprises a winder body and is divided into a wound silk placement portion and a cloth winding portion, the wound silk placement portion comprises a support, multiple wound silk supporting rods are arranged on the support, the cloth winding portion comprises an underframe, a driving mechanism, a transmission mechanism and a winding mechanism, and a first guide roller and a second guide roller are arranged on the underframe; each wound silk supporting rod comprises a fixed rod and a wound silk barrel, one end of each fixed rod is provided with a thread, a fixed block is arranged at the end of each thread, each wound silk barrel is arranged on the corresponding fixed rod, each fixed rod is fixed on the support, and a limiting device is arranged on the underframe and comprises an L-shaped retaining plate fixed on the underframe. The winder is formed by further improving existing equipment, thereby being high in production efficiency, more orderly in winding, lowered in fault rate, suitable for mass production of woven bags and high in practicability.

Owner:TIANJIN XUHUIHENGYUAN PLASTIC PACKAGING CORP

Slitting machine for glass cloth adhesive tape processing and slitting method thereof

PendingCN114803645AGuarantee the quality of windingGuaranteed smoothFunction indicatorsArticle deliveryCloth adhesive tapeEngineering

The invention discloses a dividing and cutting machine for glass cloth adhesive tape processing and a dividing and cutting method of the dividing and cutting machine in the field of adhesive tape production, the dividing and cutting machine comprises an unwinding mechanism, a dividing and cutting mechanism and a winding mechanism which are arranged on a rack, and a first leveling mechanism is arranged between the unwinding mechanism and the dividing and cutting mechanism; a second leveling mechanism is arranged between the slitting mechanism and the winding mechanism, the winding mechanism comprises a winding roller rotationally installed on the rack, and a speed control unit used for measuring the winding thickness of the winding roller and adjusting the rotating speed change of the winding roller according to the winding thickness change is arranged beside the winding roller. The speed control unit comprises a measuring assembly and a speed regulation transmission assembly. According to the winding device, the peripheral thickness of the winding roller can be measured in real time when the winding roller conducts winding, the rotating speed of the winding roller is adjusted to be changed according to the winding thickness change, the actual winding speed of the winding position is kept constant, and the winding quality can be guaranteed while the winding efficiency is guaranteed.

Owner:程楚楚

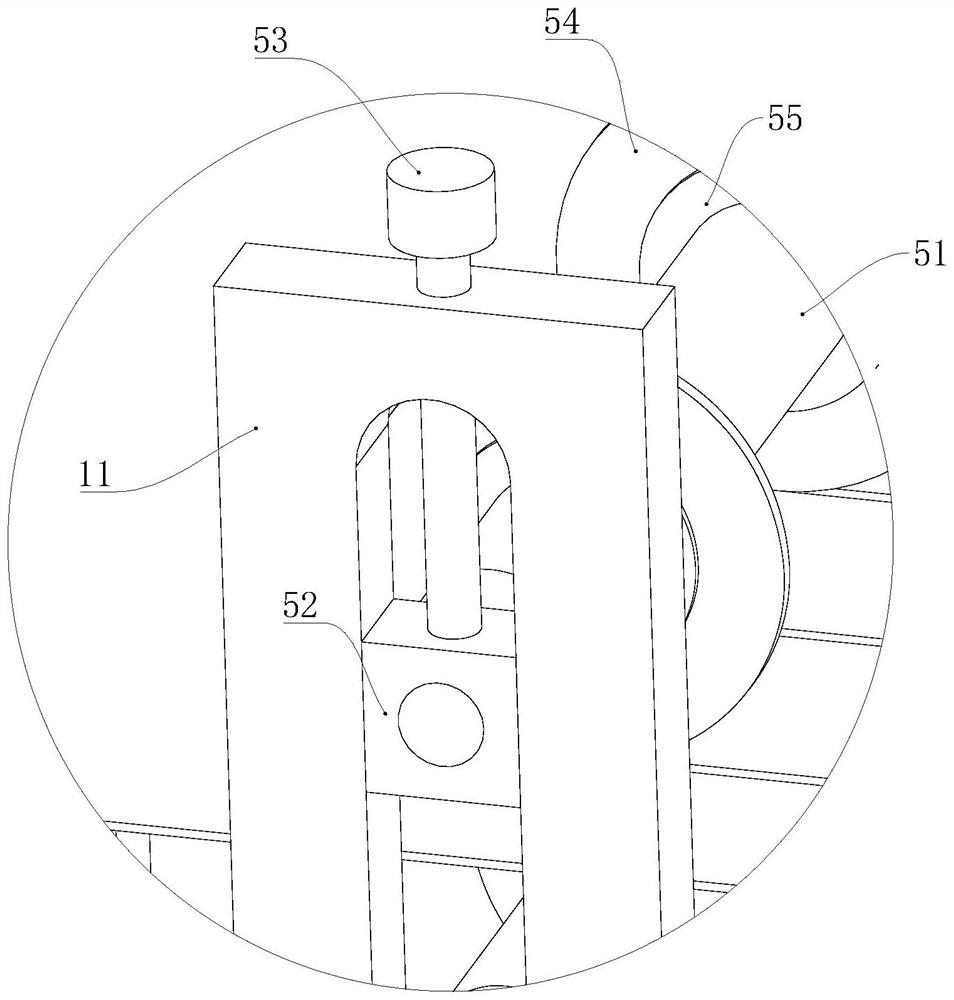

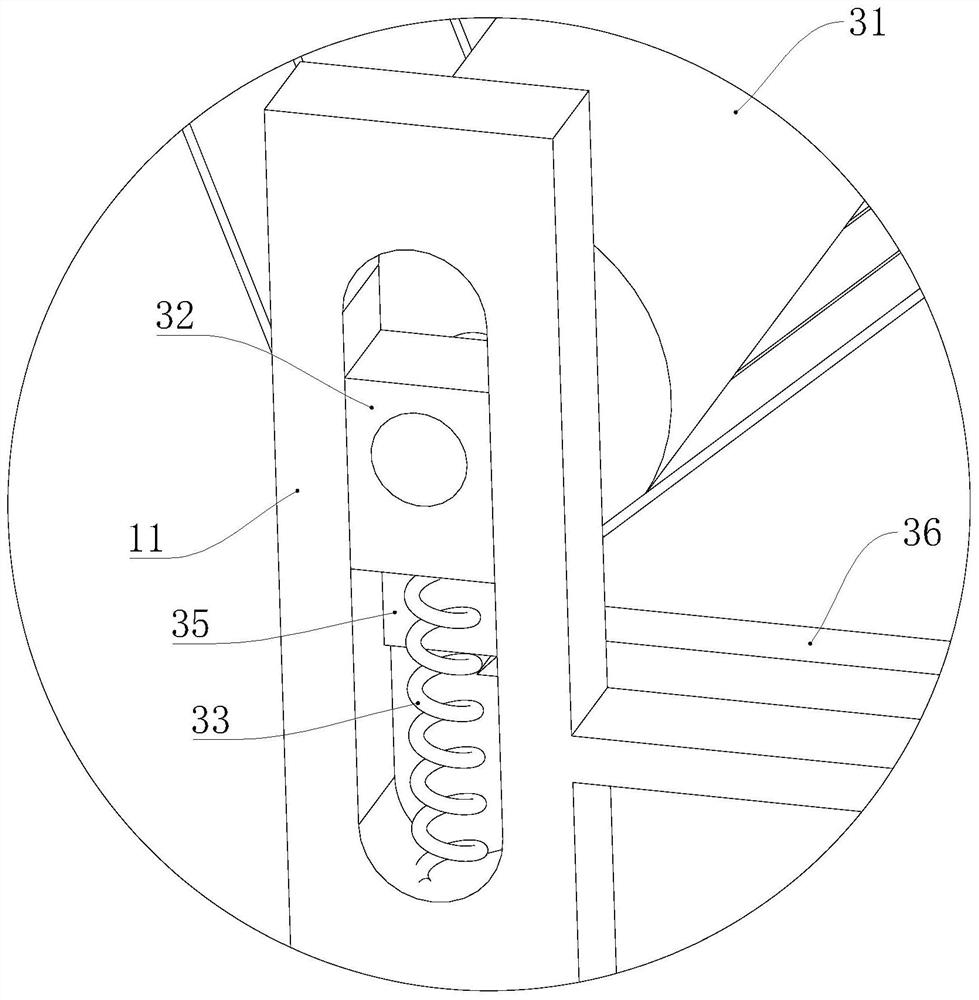

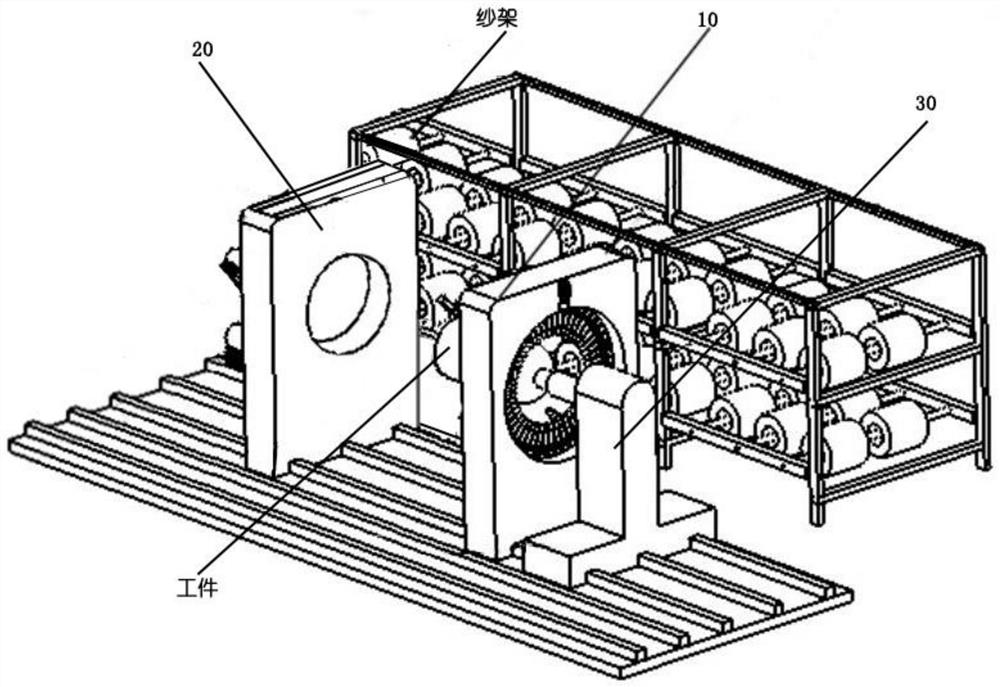

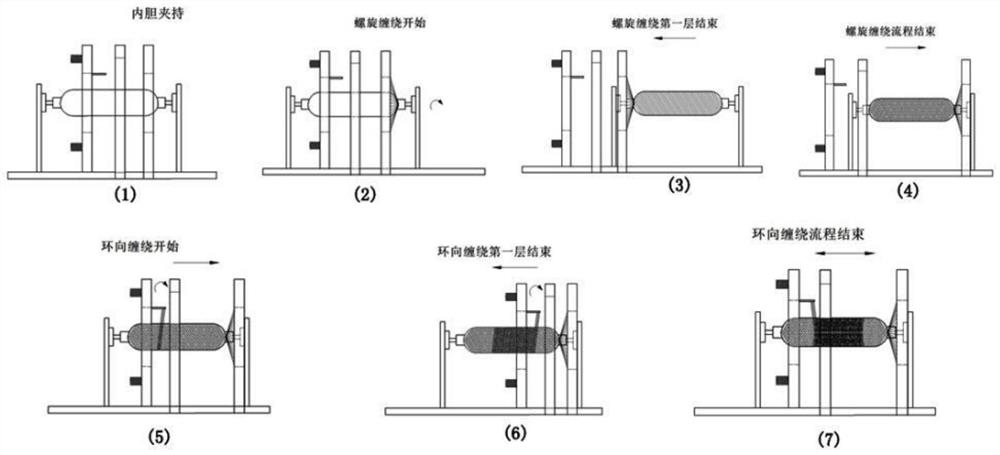

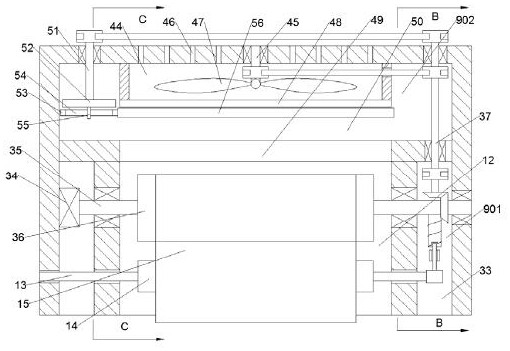

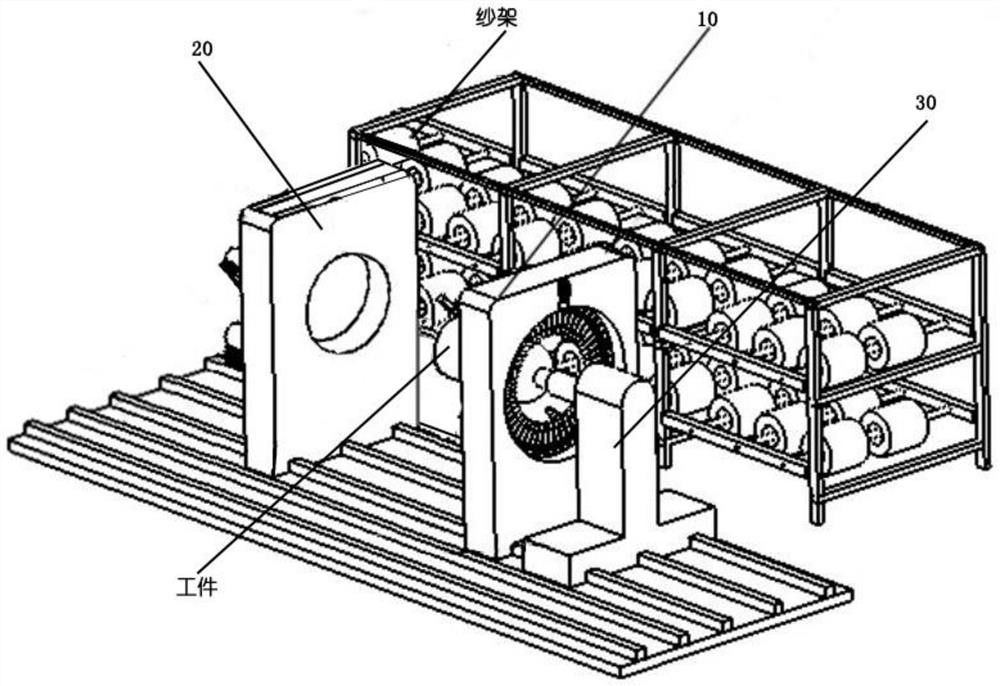

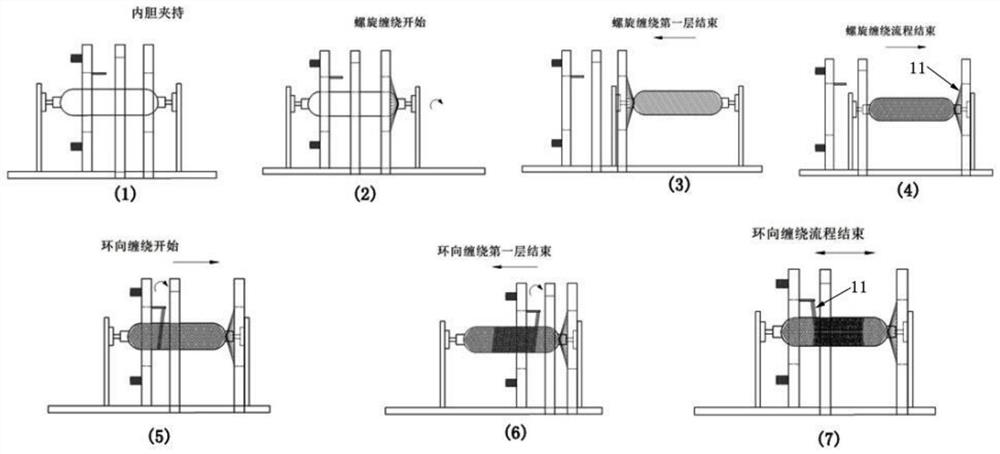

Fiber winding device

The invention belongs to the technical field of fiber winding, and particularly relates to a fiber winding device. The device comprises a spiral winding device, an annular winding device and a fixing device, a workpiece is clamped through the fixing device and driven to rotate in the radial direction and move in the axial direction, and spiral winding is conducted through the spiral winding device; annular winding is conducted through the annular winding device; the spiral winding device comprises a frame body and a plurality of silk guide heads, a second through hole is formed in the frame body, the plurality of silk guide heads are annularly distributed along the center of the second through hole and are rotationally connected with the frame body, and fibers can extend out of each silk guide head; a first driving mechanism is arranged on the frame body, and each silk guide head is driven to rotate through the first driving mechanism; and the annular winding mechanism comprises a rack, a fixing plate, a fiber bundle cylinder, a bundling device and a silk guiding piece, the fixing plate is rotationally connected with the rack, the fixing plate is connected with a driving element, and the fixing plate is driven to rotate through the driving element. Through the device, the winding efficiency and the winding quality can be improved.

Owner:TAIYUAN UNIV OF TECH

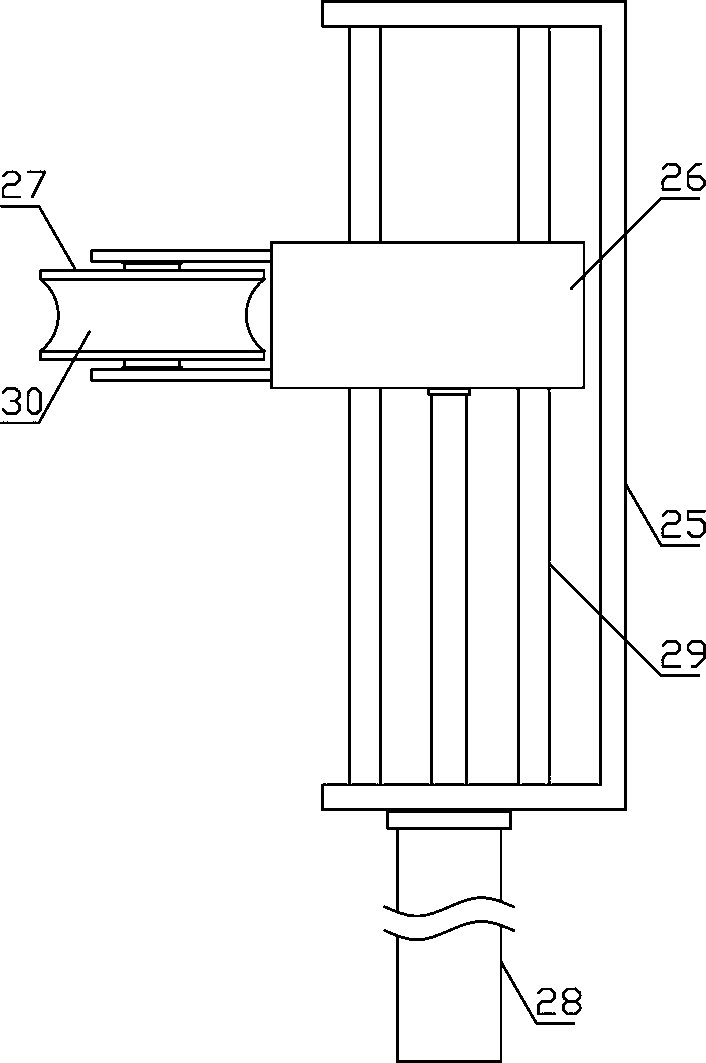

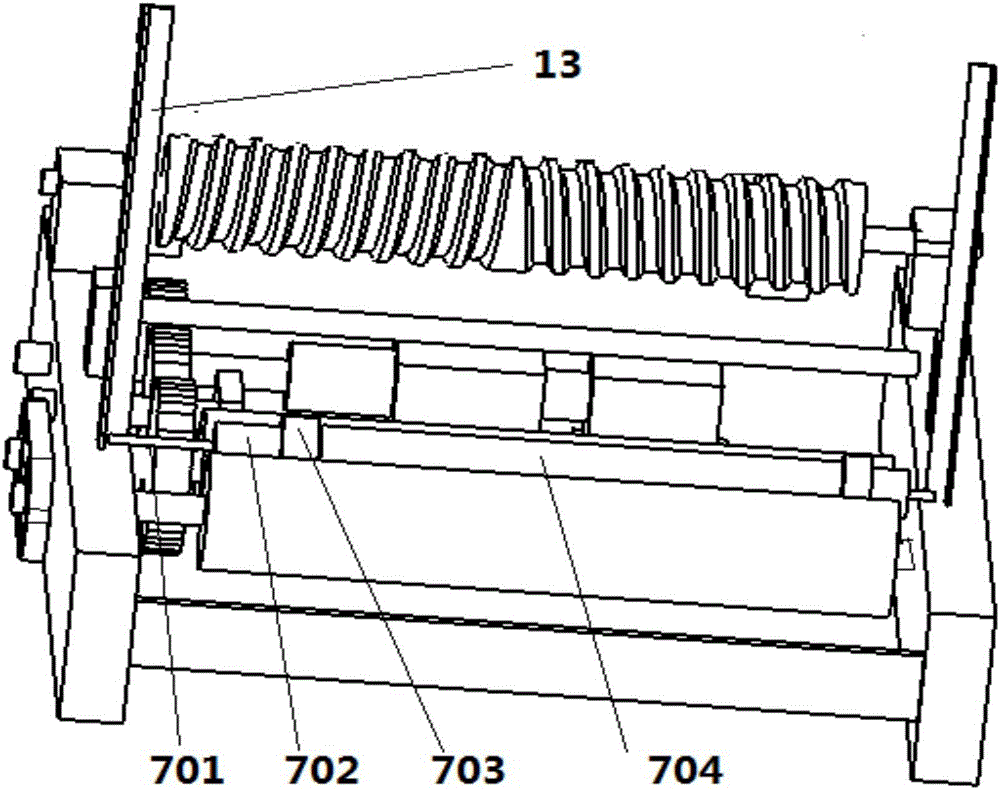

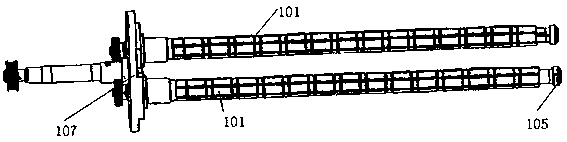

Single and double coil head universal carbon fiber warping machine winding device and constant tension control method

ActiveCN110902452AGuaranteed winding efficiencyConstant tension control method is simpleWebs handlingYarnFiber

The invention provides a single and double coil head universal carbon fiber warping machine winding device. The carbon fiber warping machine winding device comprises a traction roller, at least one tension adjusting device, at least one tension swing roller, a fixing transition roller, an air expansion shaft and a servo motor, wherein the traction roller is used for drawing carbon fibers through rotation; the fixing transition roller is arranged above the air expansion shaft in parallel; the servo motor is used for driving the air expansion shaft to rotate; the air expansion shaft at least contains one wide-door-width winding coil head or simultaneously contains two narrow-door-width winding coil heads; when the wide-width winding coil head is used for winding, one tension swing roller isarranged, and the tension adjusting device is arranged on one side of the tension swing roller; and when two narrow-door-width winding coil heads are used for winding, the two tension swing rollers are arranged, and the tension adjusting devices are respectively arranged on one sides, away from each other oppositely, of the two tension swing rollers. According to the single and double coil head universal carbon fiber warping machine winding device and a constant tension control method, compared with the prior art, the switching winding of a single wide-door-width carbon fiber yarn sheet and adouble narrow-door-width carbon fiber expanded yarn sheet can be achieved by replacing the winding coil head and the tension swing rollers.

Owner:NEWTRY COMPOSITE

Rubber production pouring device and pouring method

PendingCN112810007AAvoid the phenomenon of replacing the support shaftShorten the timeBeltsMelting tankMechanical engineering

The invention relates to the technical field of production and processing of rubber, and discloses a rubber production pouring device. The rubber production pouring device comprises a base, wherein supporting legs are fixedly connected with the upper surface of the base, a melting tank is fixedly connected with the upper ends of the supporting legs, a discharging pipe is fixedly connected with the lower end of the melting tank, an electromagnetic valve is arranged on the discharging pipe, a sleeve is fixedly connected with the upper end of the base, the sleeve is of a hollow structure, and does not comprise a left side surface, a quick rubber belt forming device is arranged in the sleeve, a supporting board is fixedly connected with the upper end of the base, and an arc groove is formed in the upper end of the supporting board. According to the rubber production pouring device and a rubber production pouring method, by arranging a conical pushing rod, winding rollers of different diameters can be supported according to the requirements, thus the phenomenon that a supporting shaft needs to be replaced for the winding rollers of the different diameters is avoided, and then the time wasted in replacing the supporting shaft is shortened, so that the working efficiency is improved, and the labor intensity of an operator is reduced.

Owner:周俊玉

Equipment for flocking production

InactiveCN107008630AGuaranteed efficiencyReduces fabric wrinklingLiquid surface applicatorsCoatingsEngineeringHigh pressure

The invention provides equipment for flocking production. The equipment comprises a stretching mechanism, a flocking mechanism, a dust removing mechanism and a rolling mechanism. The flocking mechanism is arranged on one side of the stretching mechanism. The dust removing mechanism is arranged on one side of the flocking mechanism. The rolling mechanism is arranged on one side of the dust removing mechanism. The stretching mechanism comprises a cloth feeding roller, a stretching roller and a stretching area. The flocking mechanism comprises a fluff adding device, a high-voltage electrode, a base material and a flapping rod, and the base material is located on one side of the stretching area. The dust removing mechanism is internally provided with a draught fan and a dust suction device. The rolling mechanism is internally provided with a tension roller, a flattening roller, a guiding roller, a pressing roller, a rolling roller, a rotary disc and an empty roll core. The dust removing mechanism is arranged in the equipment and internally provided with the draught fan and the dust suction device. A large amount of batting is possibly left on fabric obtained after flocking just now, when the fabric passes through the dust removing mechanism, the draught fan can blow the left batting up, the dust suction device sucks the batting in, and surface cleanliness and tidiness of the fabric are kept.

Owner:JIASHAN SHENGLAISI CASHMERE

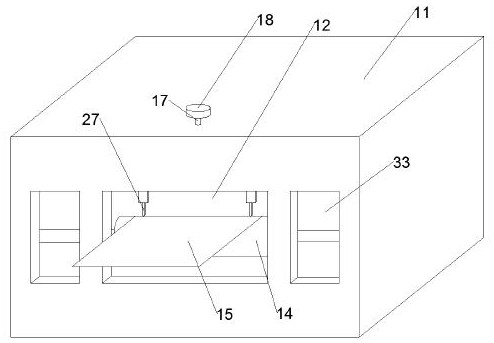

Winding and cutting device for paper tube production

PendingCN113211879ANot prone to cloggingGuaranteed winding efficiencyPaper/cardboard wound articlesMachiningIndustrial engineering

The invention relates to the technical field of paper straw machining equipment, in particular to a winding and cutting device for paper tube production. The device comprises a case, a winding rod arranged on the case and paper feeding equipment for winding paper on the winding rod, wherein the case is provided with a transverse movement rotating mechanism used for lifting the winding rod and driving the winding rod to rotate and a multi-station synchronous cutting mechanism; and the transverse movement rotating mechanism comprises a reciprocating transverse movement mechanism and a rotating lifting component, the reciprocating transverse movement mechanism comprises a transverse movement base and a transverse movement driving mechanism used for driving the transverse movement base to move in a reciprocating mode, the rotating lifting component comprises two rotating rods arranged on the transverse movement base side by side and a rotating driving mechanism arranged on the transverse movement base, and a pressure monitoring mechanism connected to the end part of the winding rod is arranged on the case. According to the winding and cutting device, the structure is simple, multi-layer paper can be wound on the winding rod in a high-efficiency and high-quality mode, the phenomena of paper blocking and paper clamping are not prone to occurring, and the winding efficiency and the winding quality of paper straws in the production process are improved.

Owner:芜湖大正百恒智能装备有限公司

Filament spinning, winding and producing method

ActiveCN107964711AAffect qualityAffect the winding processFilament handlingMelt spinning methodsEngineeringPulp and paper industry

The invention provides a filament spinning, winding and producing method. The method is characterized by comprising the following specific steps that firstly, a Corterra filament tow is wound; secondly, the Corterra filament tow is fully drawn, wherein the Corterra filament tow is subjected to low-temperature heating through a first spinning hot roller set composed of a hot roller capable of beingheated and a separator roller which is not heated, then the Corterra filament tow obtained after low-temperature heating is drawn into Corterra filaments through a second spinning hot roller set composed of a hot roller capable of being heated and a separator roller which is not heated, and the Corterra filaments are subjected to primary high-temperature heat setting; thirdly, the Corterra filaments obtained after primary high-temperature heat setting are subjected to independent high-temperature heat setting through a third spinning hot roller set composed of a hot roller capable of being heated and a separator roller which is not heated, and Corterra fully-drawn filaments are formed.

Owner:南通苏源化纤有限公司

Rolling holder for cloth weaving machine

The invention provides a rolling holder for a cloth weaving machine. The rolling holder comprises a rolling machine body which is divided into a rolled yarn setting part and a cloth rolling part. The rolled yarn setting part and the cloth rolling part are connected by means of a circular weaving machine. The rolled yarn setting part comprises a support on which a plurality of rolled yarn supporting rods are arranged. The cloth rolling part comprises a pedestal, a driving mechanism, a transmission mechanism, and a rolling mechanism. A first guide roll and a second guide roll are arranged on the pedestal. The rolling mechanism is placed between the two guide rolls. A limiting device is arranged on the pedestal, and comprises L-shaped baffle plates. The rolling mechanism is located between and in clearance with two L-shaped baffle plates. According to the rolling holder for a cloth weaving machine proposed by the invention, further improvements are made for the defects of an existing spool fixing device, such that a spool can be fixed more stably during operating of the equipment, and cloth can be rolled more regularly; in addition, the rolling holder is strong and durable in own structure, and therefore, the probability of breakage thereof is reduced, and the maintenance cost of the equipment is reduced.

Owner:TIANJIN XUHUIHENGYUAN PLASTIC PACKAGING CORP

Anti-loosening fiber cloth adhesive tape winding device

The invention relates to the technical field of fiber cloth adhesive tape winding, and discloses an anti-loosening fiber cloth adhesive tape winding device. The device comprises a workbench and supporting legs, the workbench is connected with the supporting legs, an adjusting frame is arranged on the outer side of the workbench and connected with the workbench, a winding motor is arranged on the inner side of the adjusting frame, the winding motor is connected with the adjusting frame, one side of the winding motor is provided with a winding roller, the winding roller is in contact with the adjusting frame, one side of the winding roller is provided with an auxiliary rod, the auxiliary rod is connected with the adjusting frame, the outer side of the adjusting frame is provided with a mounting frame, and the mounting frame is connected with the adjusting frame. According to the anti-loosening fiber cloth adhesive tape winding device provided by the invention, the adhesive tape can be conveniently wound, and compared with a common winding device, the winding device provided by the invention can conveniently perform winding, and can avoid the phenomenon that the adhesive tape is manually loosened in the later period.

Owner:江苏瑞恩新材料有限公司

High-efficiency fiber spiral winding device

The invention belongs to the technical field of fiber winding devices, and particularly relates to a high-efficiency fiber spiral winding device. The high-efficiency fiber spiral winding device comprises a frame body and yarn guide heads; a through hole is formed in the frame body; the plurality of yarn guide heads are arranged, are annularly distributed along the center of the through hole and are rotationally connected with the frame body; fibers can extend out of each yarn guide head; a first driving mechanism is arranged on the frame body; and the yarn guiding heads are driven to rotate through the first driving mechanism. The led-out fibers can be uniformly distributed on the outer surface of the pressure vessel in a net shape; and the first driving mechanism drives the yarn guide heads to rotate to change the angles of the fibers, and winding is completed in cooperation with rotation and movement of the pressure vessel. When the high-efficiency fiber spiral winding device is used for winding, the fibers can be uniformly distributed and are not overlapped or crossed, so that the use of the fibers can be effectively reduced while the winding efficiency is ensured.

Owner:TAIYUAN UNIV OF TECH

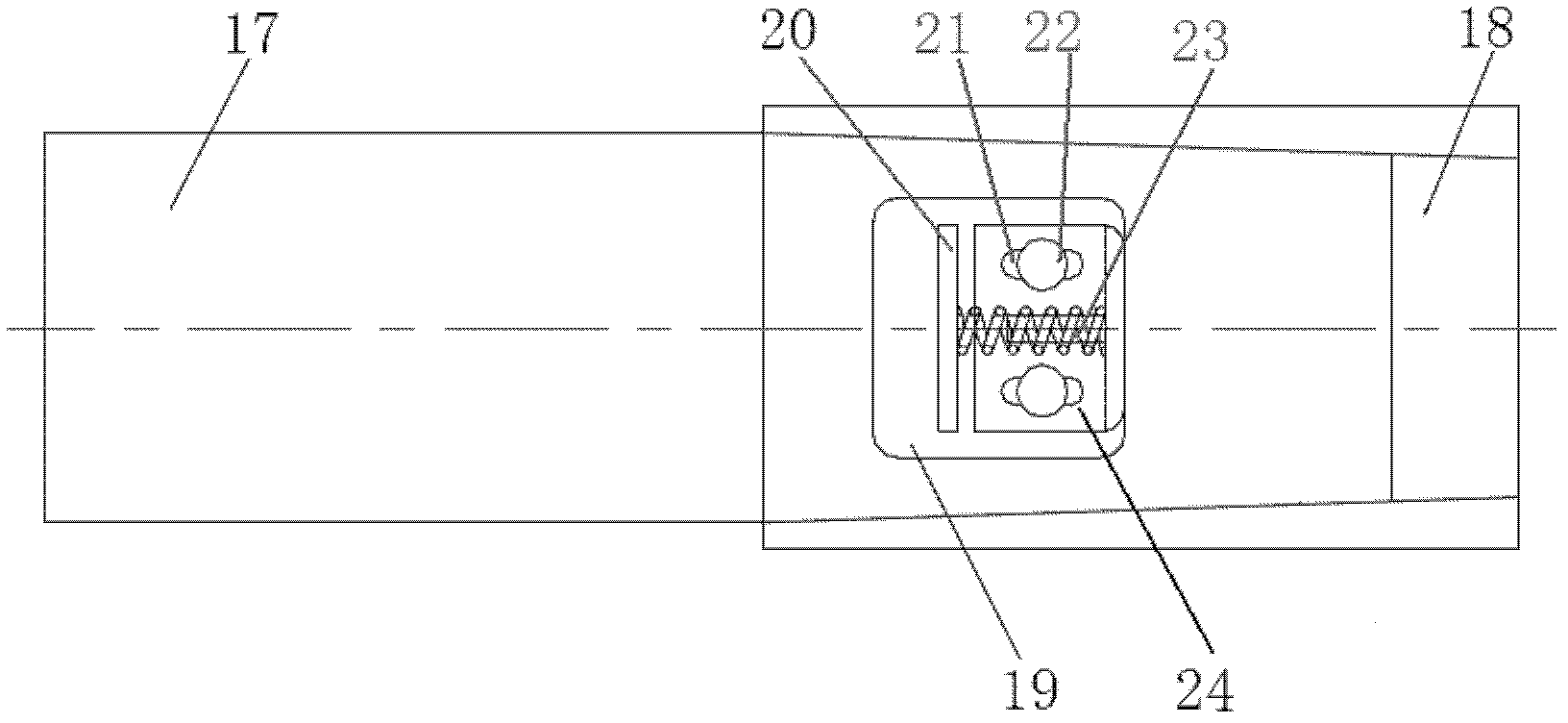

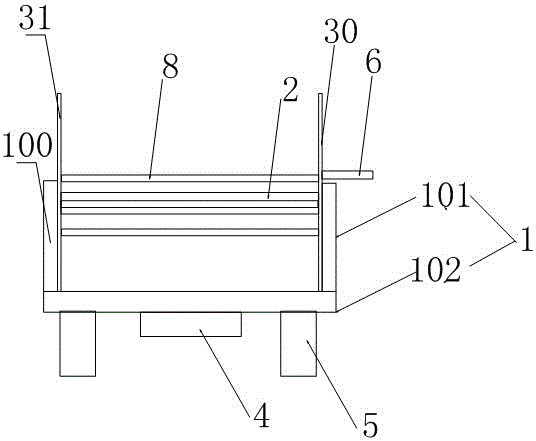

A winding device for non-woven fabrics

ActiveCN113415660BExtended storage timeKeep healthyDispersed particle filtrationArticle deliveryGear driveGear wheel

The invention discloses a rolling device for non-woven fabrics, which includes a box body. A curling chamber with an opening forward is arranged in the box body. A winding mechanism is arranged in the curling chamber. The invention utilizes the principle of gear transmission and The principle of belt transmission, when the non-woven fabric is rolled, the support roller is always used to keep the non-woven fabric flat on the lower side of the non-woven fabric. When it becomes thicker and thicker, the position is automatically adjusted to ensure the winding efficiency, so that the non-woven fabric is always kept flat. Moreover, the device can also perform dust removal on the non-woven fabric during winding, and collect and process the absorbed dust to ensure While ensuring the dust removal efficiency, the health of the staff is guaranteed, and the storage time of the non-woven fabric after curling is prolonged. Not only that, the device can also cut the non-woven fabric during winding, and the user can freely adjust the cutting width, saving time save effort.

Owner:南通汇优嘉医用材料有限公司

A fiber winding device

The invention belongs to the technical field of fiber winding, and specifically relates to a fiber winding device, which includes a spiral winding device, a hoop winding device and a fixing device. The fixing device clamps the workpiece and drives the workpiece to rotate radially and move axially. The device is used for spiral winding; the hoop winding device is used for hoop winding; the helical winding device includes a frame body and a guide wire head, the frame body is provided with a second through hole, and several guide wire heads are provided along the The center of the second through hole is circularly distributed and connected with the frame body in rotation, and fibers can protrude from each guide wire head; the frame body is provided with a first driving mechanism, which drives each wire guide head to rotate through the first drive mechanism; The directional winding device includes a frame, a fixed plate, a fiber bundle tube, a bundle device and a wire guide, the fixed plate is rotatably connected with the frame, the fixed plate is connected with a driving element, and the fixed plate is driven to rotate through the driving element. The device can improve winding efficiency and winding quality.

Owner:TAIYUAN UNIV OF TECH

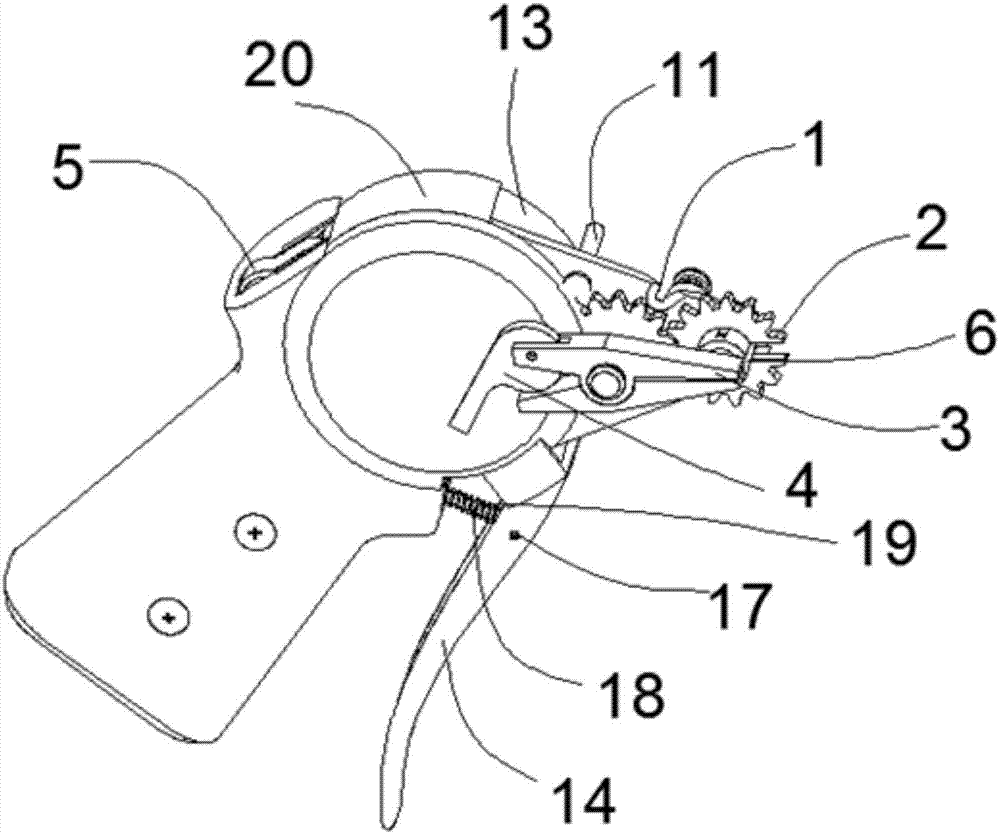

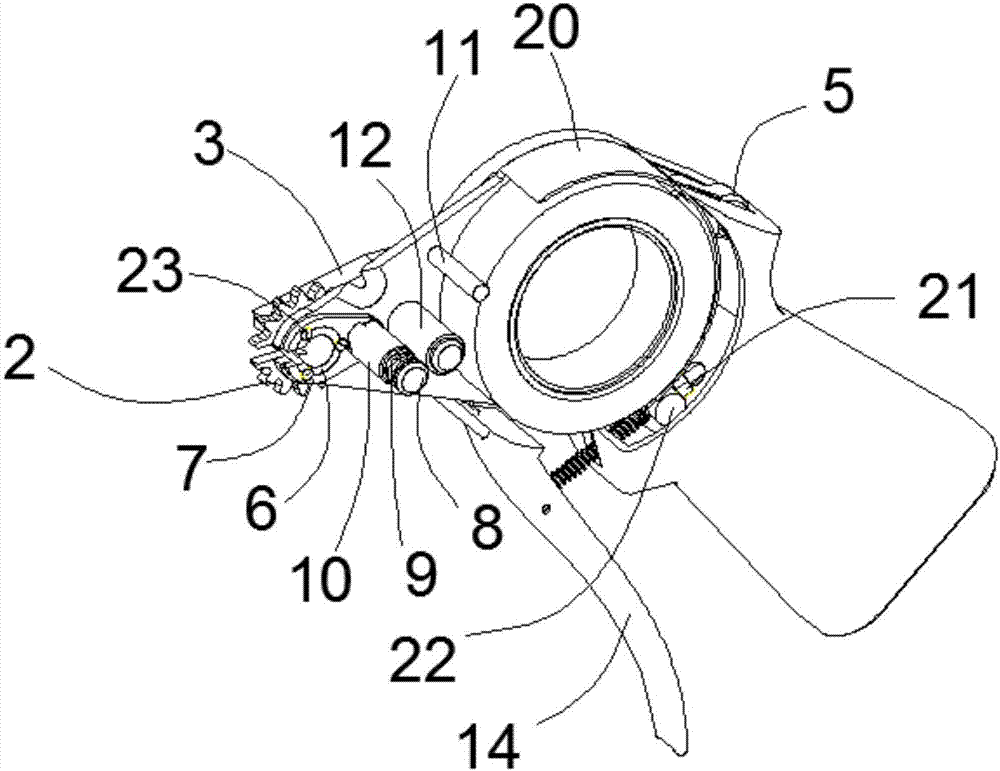

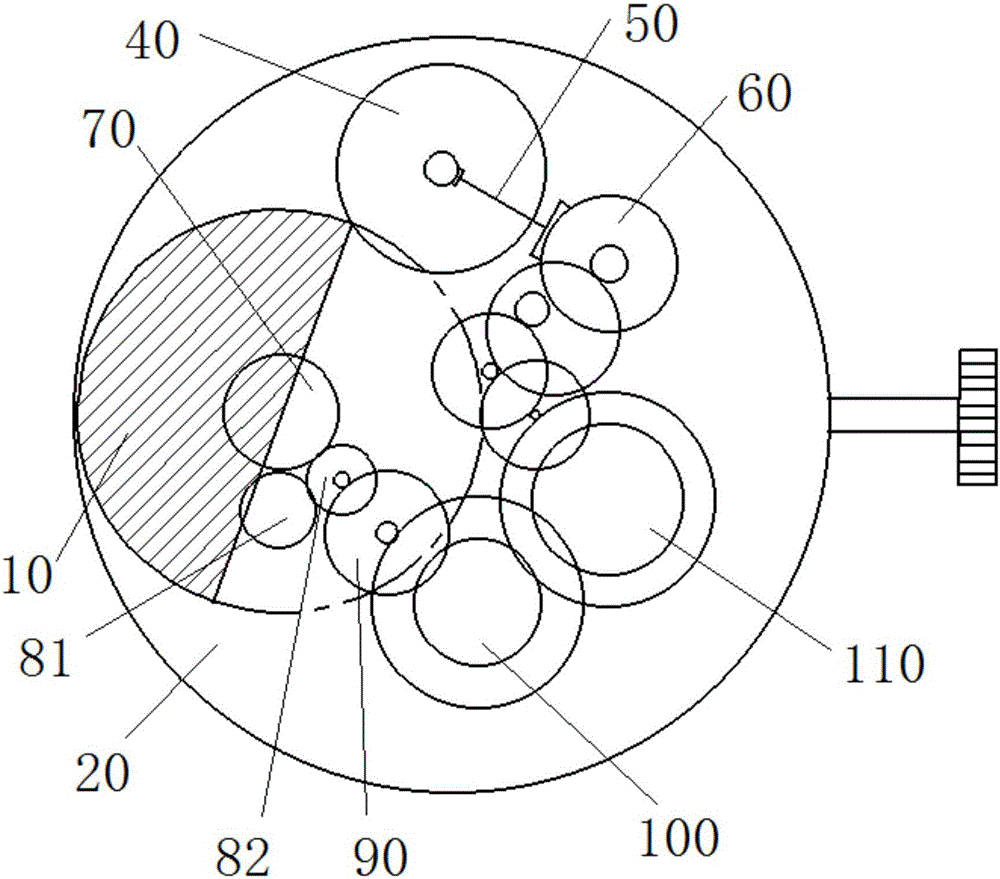

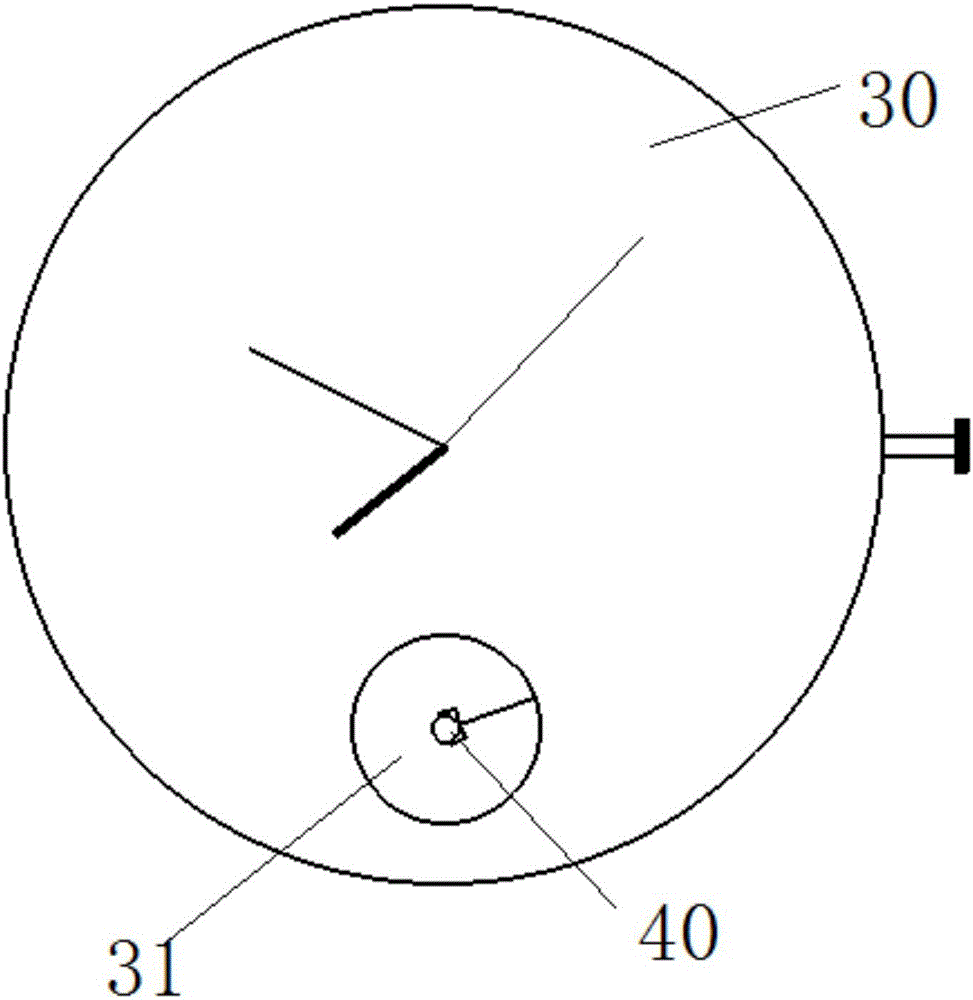

Movement and mechanical watch with same

ActiveCN106773591AGuaranteed efficiencyGuaranteed reliabilityGearworksEscapementsEngineeringClockwork

The invention discloses movement and a mechanical watch with the movement and belongs to the technical field of watches. The movement comprises a movement clamp plate and a rotatable automatic rotor, the clamp plate is located at the back of the movement, the automatic rotor and the movement clamp plate are on the same layer and eccentrically arranged relative to the center of the movement, and the radius of the automatic rotor exceeds half of the radius of the movement to allow the rotation trajectory of the automatic rotor covers the center of the movement. Compared with movement of the same size, the movement has the advantages that the size of the automatic rotor is larger than the size of a pearl rotor in the prior art, the movement is high in movement ability, a clockwork spring can be driven by power generated by self-weight, and the winding efficiency and reliability of the movement are guaranteed.

Owner:南通市知识产权维权援助中心

Cable reels for easy transport

The invention discloses a cable reel that is convenient for transportation. The cable reel is arranged on a load-bearing plate capable of bearing load, and load-bearing wheels are installed under the load-bearing plate, so that the load-bearing mode is controlled by the point between the previous pulley and the support rod. The force becomes the force on the surface between the pulley and the load-bearing plate, so that the porter can save the transportation labor, reduce the excessive consumption of labor, and save labor in the process of moving the cable.

Owner:STATE GRID SICHUAN ELECTRIC POWER CO

A metal wire winding device

The invention discloses a metal wire winding device. The metal wire winding device comprises a track base, and the track base is provided with parallel track grooves; a first track plate and a secondtrack plate are arranged on the top side of the track base and arranged side by side, and a fixing pin is arranged between the first track plate and the second track plate; a reciprocating air cylinder is fixedly installed on one side of the track base through a bolt and horizontally arranged, and an output rod of the reciprocating air cylinder is fixedly connected with one side of the first trackplate; and rotating fixed bases are connected to the top sides of the first track plate and the second track plate correspondingly, and a connecting rod and an I-shaped rotating part are rotatably connected to the interior of each rotating fixed base. According to the metal wire winding device, the wire breaking phenomenon is avoided while the winding efficiency is guaranteed, orderly and continuous conduction of wire winding is guaranteed, the production efficiency is improved, the labor force is saved, wire winding is more uniform, and the using requirements of people in production and lifeare met.

Owner:天长市恒鑫机电设备有限公司

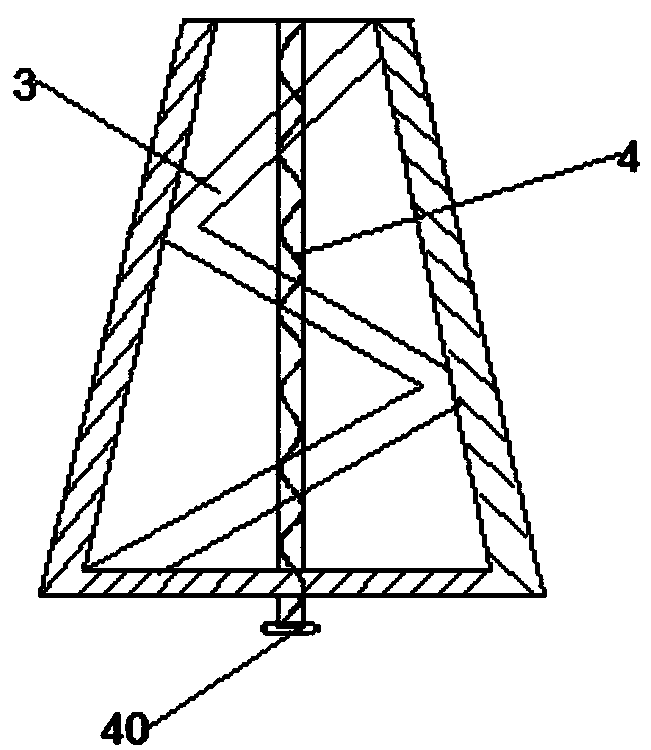

New technology for mucilage glue flat monofilament post-processing

InactiveCN103628264AShort processEasy to operateNew-spun product collectionTextile treatment carriersDyeingEngineering

The invention provides a new technology for mucilage glue flat monofilament post-processing to solve the problem that the mucilage glue flat monofilament post-processing procedure is complex. The new technology is characterized in that the working procedures comprise spinning, processing through a loosening barrel, post-processing, dyeing, drying and barrel forming, a thread line spun through a spinning machine can be wound into a barrel easily through the loosening barrel, the post-processing and the dyeing processes are finished in a barrel-shaped vat, and the thread line is dried and wound into a finished product. A liquid leaking hole is formed in a barrel tube of the loosening barrel, the aperture of the liquid leaking hole becomes a small-to-large conical shape from the inner wall of the loosening barrel to the outer wall of the loosening barrel, the internal aperture ranges from 6mm to 10mm, and the external aperture ranges from 7mm to 12mm. The new technology process is short and convenient to operate, cost is saved, and the field environment is improved.

Owner:YIBIN GRACE +2

Cable dragging device for mining machinery

PendingCN114394481AEasy to useImprove practicalityFilament handlingStructural engineeringElectric cables

The invention relates to the technical field of mining, and discloses a cable dragging device for mining machinery, which comprises a floor, and is characterized in that the surface of the floor is provided with a handle groove, the surface of the floor is fixedly provided with a wire guide plate, a second limiting piece and a first limiting piece, and the surface of the floor is movably provided with a take-up assembly. According to the winding device, the organizational structure of the limiting spring, the buckle, the L-shaped rod and the connecting column is adopted, in the using process of the winding device, the length of the winding device can be controlled according to different wire harness lengths, the using effect of the winding device can be well improved, in the using process, the buckle is pulled, then the buckle drives the L-shaped rod to extrude towards the inner side, the limiting spring rebounds, and the winding device is convenient to use. The limiting spring drives the L-shaped rod to ascend, and then the L-shaped rod drives the connecting column to ascend, so that the overall height of the take-up assembly is increased, the take-up assembly can adapt to more cables with different lengths, the practicability of the take-up assembly in the using process is improved, and the overall using effect of the take-up assembly is guaranteed.

Owner:SHANDONG HUALIAN MINING

Cable reel convenient to convey

The invention discloses a cable reel convenient to convey. A reel body of the cable reel is arranged on a bearing plate capable of bearing heavy objects; bearing wheels are arranged under the bearing plate, and a bearing mode is changed from previous point stress between pulleys and supporting rods into surface stress between the pulleys and the bearing plate, so that the conveying labor can be saved while conveying workers convey cables; excessive consumption on labor is reduced; and the cable reel convenient to convey is convenient and labor-saving.

Owner:STATE GRID SICHUAN ELECTRIC POWER

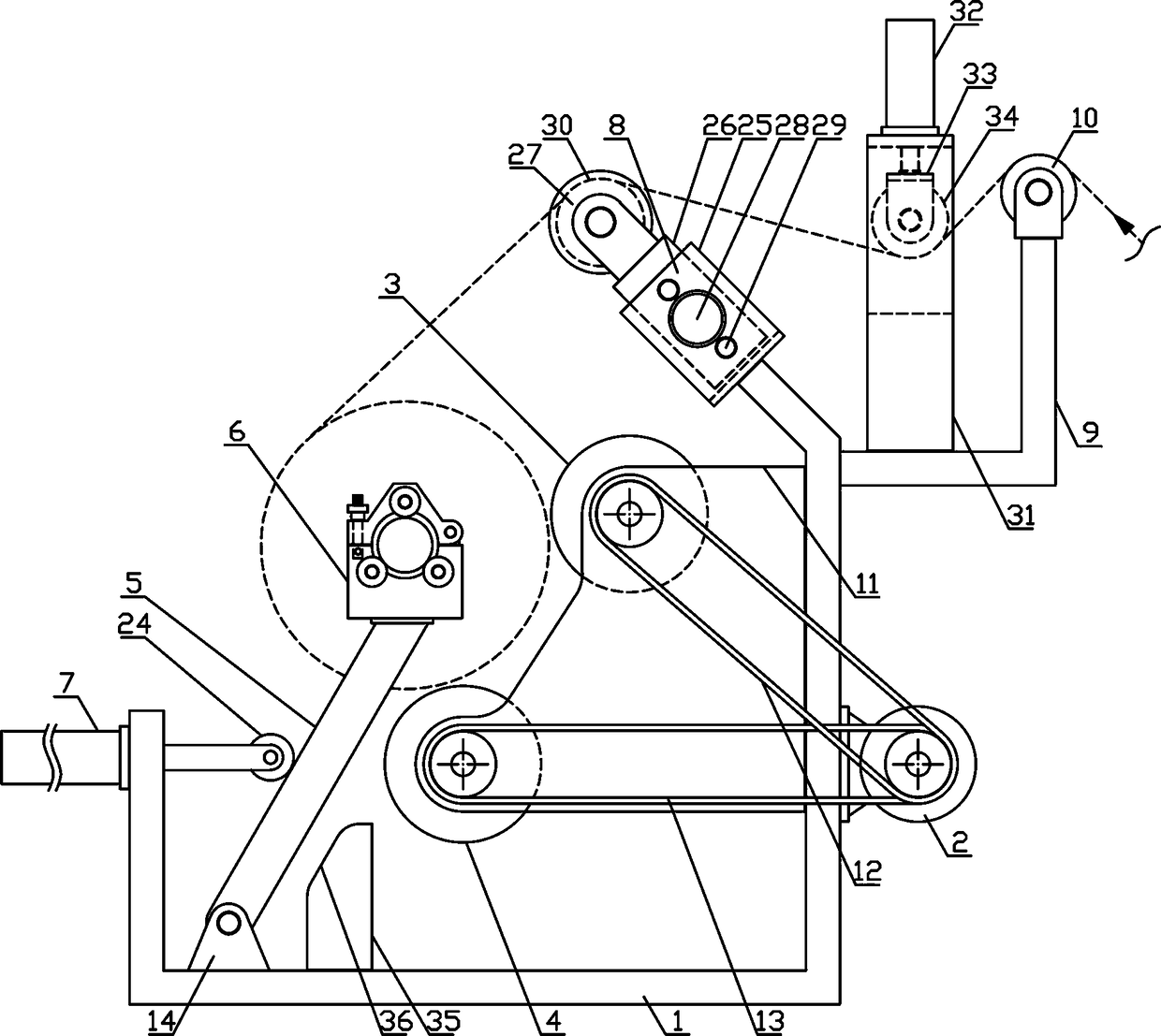

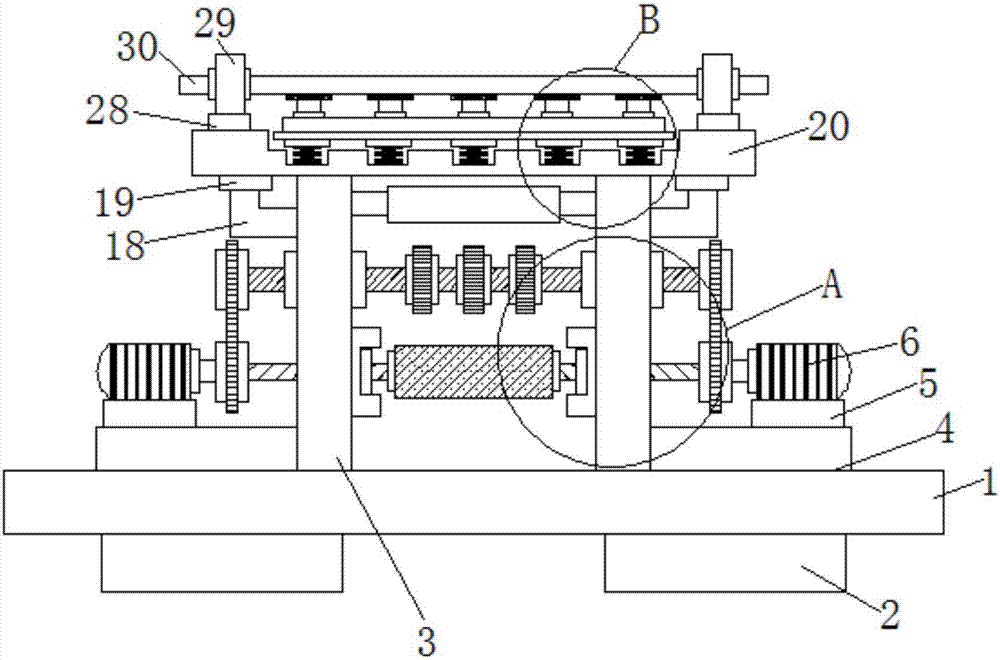

Four-axis swing arm shaft changing mechanism

ActiveCN105059975BGuaranteed winding efficiencyGuaranteed normal operationWebs handlingEngineeringMechanical engineering

The invention discloses a four-axis swing arm shaft replacement mechanism connected with a containing device used for containing and conveying adhesive tape. The four-axis swing arm shaft replacement mechanism comprises four collecting shafts used for containing paper tube sleeves and winding the adhesive tape, and one ends of the four collecting shafts are driven by a transmission mechanism to rotate. According to the four-axis swing arm shaft replacement mechanism, the collecting shafts can be used for winding, and the winding efficiency of the adhesive tape can be ensured; meanwhile, it is guaranteed that a machine can still normally operate in the discharging process, and the work efficiency of the machine is improved.

Owner:陈广辉

Wire joint butt joint auxiliary tool and use method thereof

InactiveCN113725786AImprove winding efficiencyGuaranteed winding efficiencyApparatus for joining/termination cablesApparatus for overhead lines/cablesElectrical and Electronics engineeringButt joint

The invention discloses a wire joint butt joint auxiliary tool and a use method thereof, and relates to the technical field of power construction. The device comprises an arc-shaped supporting plate, supports are fixed to the two ends of the arc-shaped supporting plate, lower half fixing rings are fixed to the tops of the supports, upper half fixing rings concentric with the lower half fixing rings are rotationally connected to the tops of the lower half fixing rings, an external threaded rod is rotationally connected between the two supports through supporting shaft sleeves fixed to the supports, the external threaded rod is slidably connected with an electric wire butt-joint winding structure which penetrates through the arc-shaped supporting plate and extends to the position below the arc-shaped supporting plate. According to the wire joint butt joint auxiliary tool and the use method thereof of the invention, an insulating tape or a steel wire can be uniformly and automatically wound at a wire connection position, so that the winding efficiency is improved, the density of the insulating tape or the steel wire wound at the wire connection position can be ensured to be consistent by rotating the external threaded rod at a constant speed, and the distances and gaps between ring layers are close, the problem of overlarge gaps or repeated winding is avoided, the winding efficiency is ensured, the winding quality is improved, and the labor intensity of workers is reduced.

Owner:张晋薄

Efficient spinning and winding production method of chemical fiber filament

ActiveCN107938004AAffect qualityAffect the winding processFilament forming substance formingNew-spun product collectionProcess engineeringHeat setting

The invention provides an efficient spinning and winding production method of chemical fiber filament. The method is characterized by comprising the following concrete steps: (1) performing a windingworking procedure on Corterra tows; (2) carrying out full drafting on Corterra long tows, wherein the step comprises: performing low-temperature heating on the Corterra tows through a first spinning heating roller group which consists of a heating roller capable of heating and a splitting roller incapable of heating, then drafting the Corterra tows, which are subjected to low-temperature heating,to form the Corterra long tows through a second spinning heating roller group which consists of a heating roller capable of heating and a splitting roller incapable of heating, and performing preliminary high temperature heat setting on the Corterra long tows; and (3) performing further independent high-temperature heat setting on the Corterra long tows, which are subjected to preliminary high-temperature heat setting, through a third spinning heating roller group, which consists of a heating roller capable of heating and a splitting roller incapable of heating, so as to form Corterra full drafting filament.

Owner:南通苏源化纤有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com