Semi-automatic winding machine and winding method for battery roll core

A winding machine, semi-automatic technology, applied in non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing, etc. , will affect the quality of the battery core, to prevent cross-infection, save production time, and stabilize the force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

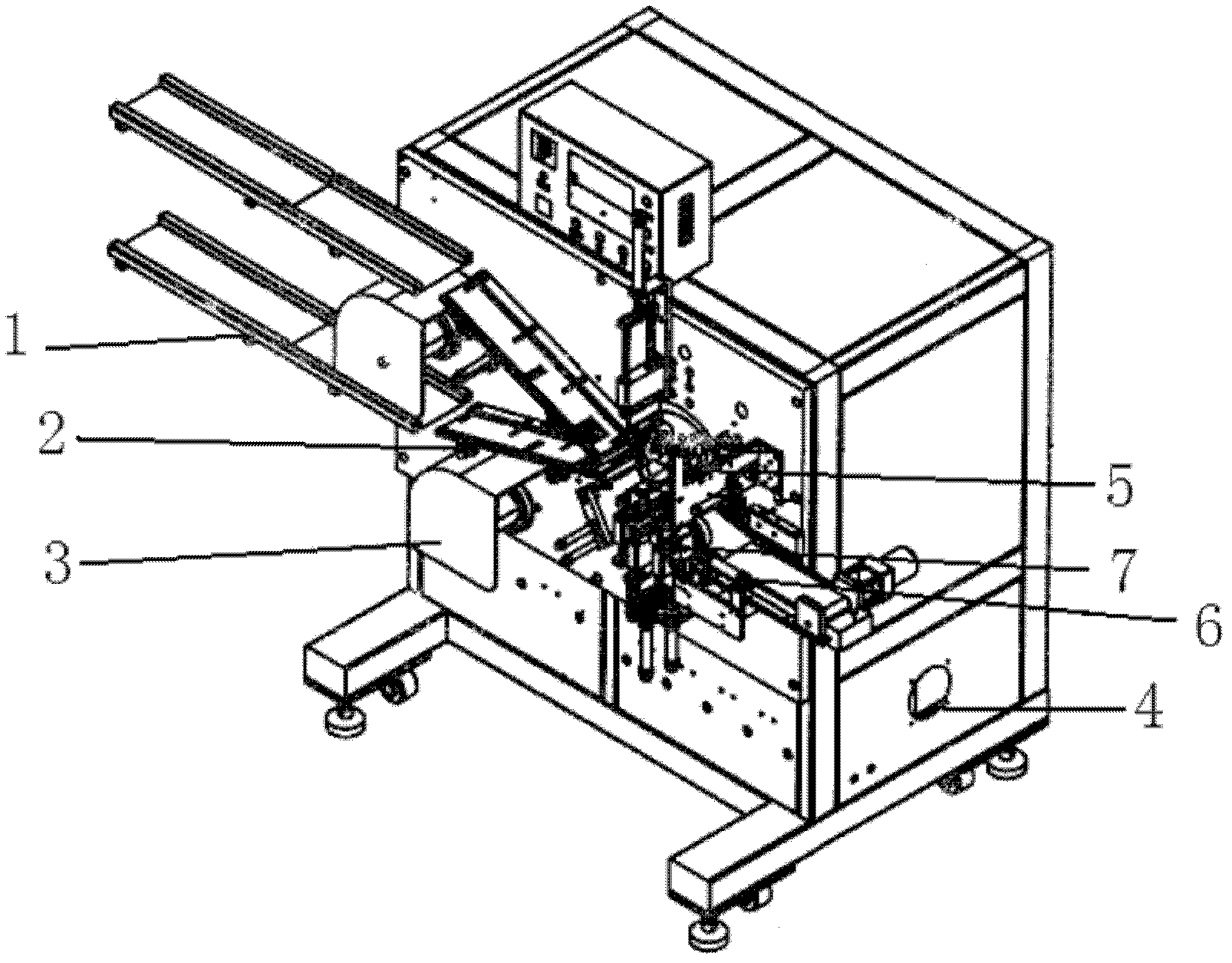

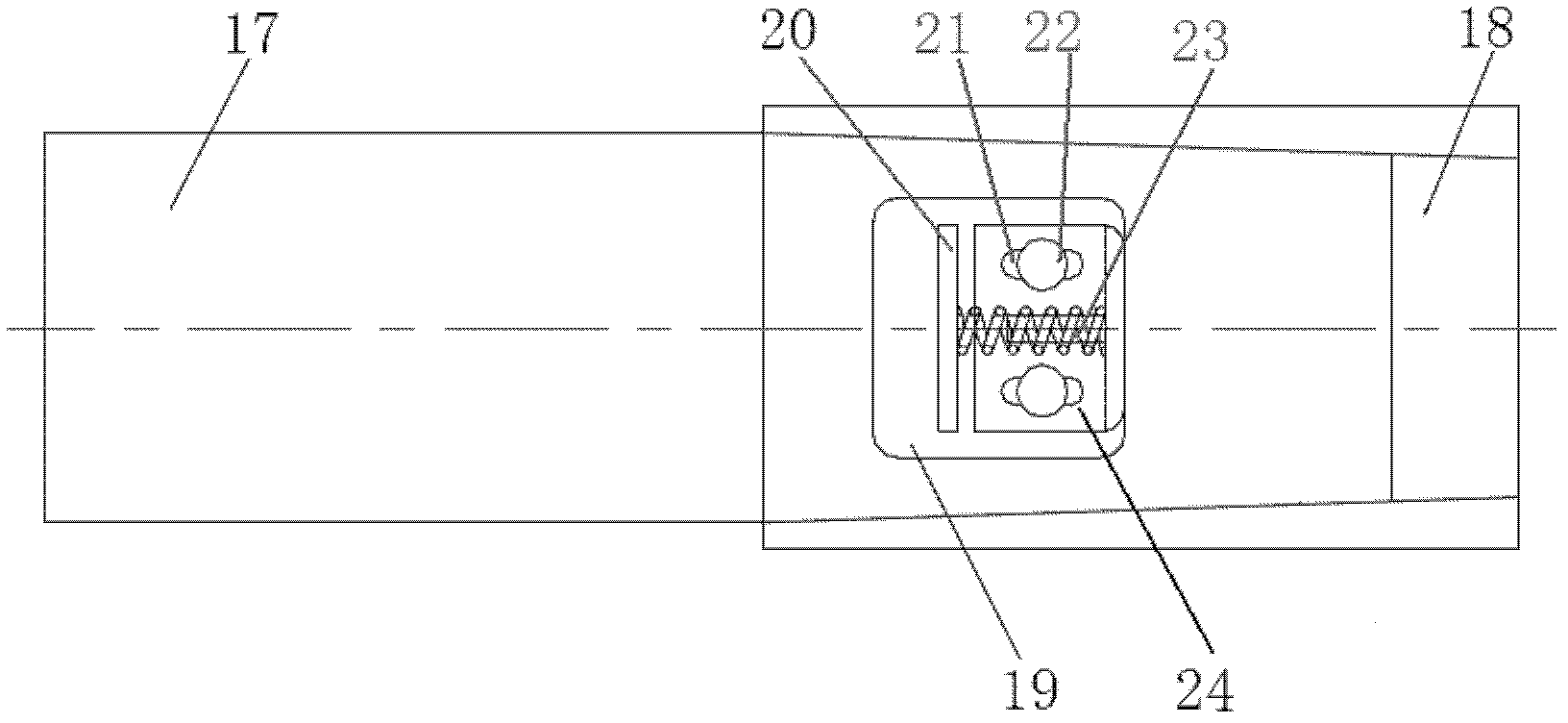

[0028] Such as figure 1 As shown, a battery core semi-automatic winding machine of the present invention includes a bracket assembly 1, a diaphragm feeding assembly 3, a frame assembly 4, a diaphragm cutting assembly 6, a blanking and pressing assembly 7, a pole piece feeding assembly 2 and a roll needle assembly 5. The pole piece feeding assembly 2 includes two guide plates for placing the positive and negative plates respectively, which are respectively the upper guide plate 8 and the lower guide plate 9, and the frame assembly 4 is provided with the positive and negative plates on the two guide plates to automatically convey Synchronous feed to needle 17.

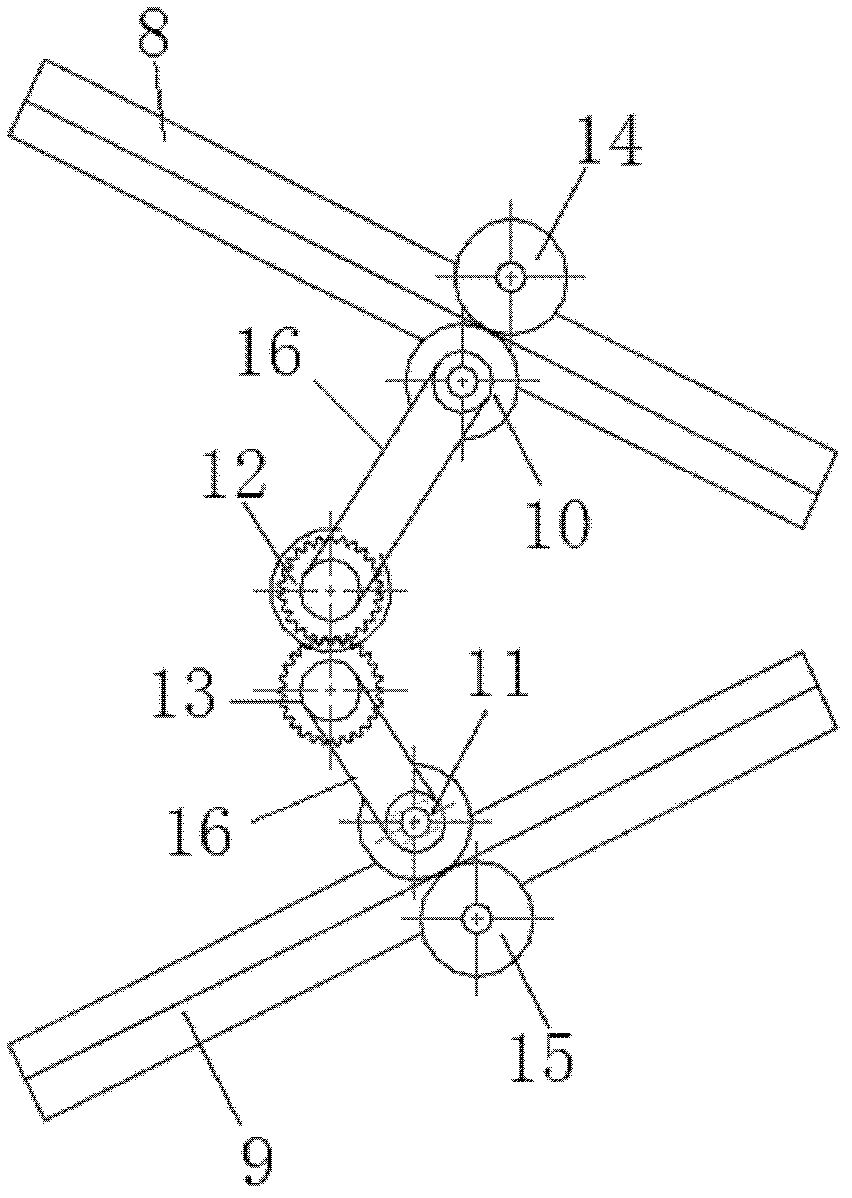

[0029] Such as figure 2 As shown, as the first improved embodiment of the battery core semi-automatic winding machine, the synchronous conveying device includes a driving motor and two driving rollers respectively arranged on the two guide plates, and the ones arranged on the upper guide plate 8 are Last driving roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com