A metal wire winding device

A technology of winding device and metal wire, which is applied in transportation and packaging, thin material processing, transportation of filamentous materials, etc. and easy to replace effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

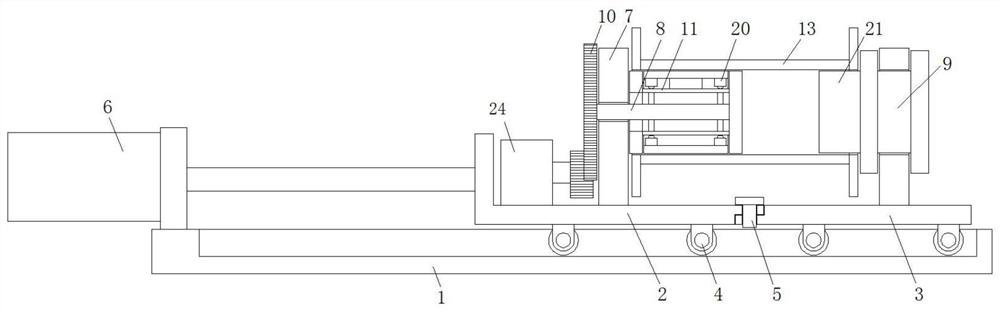

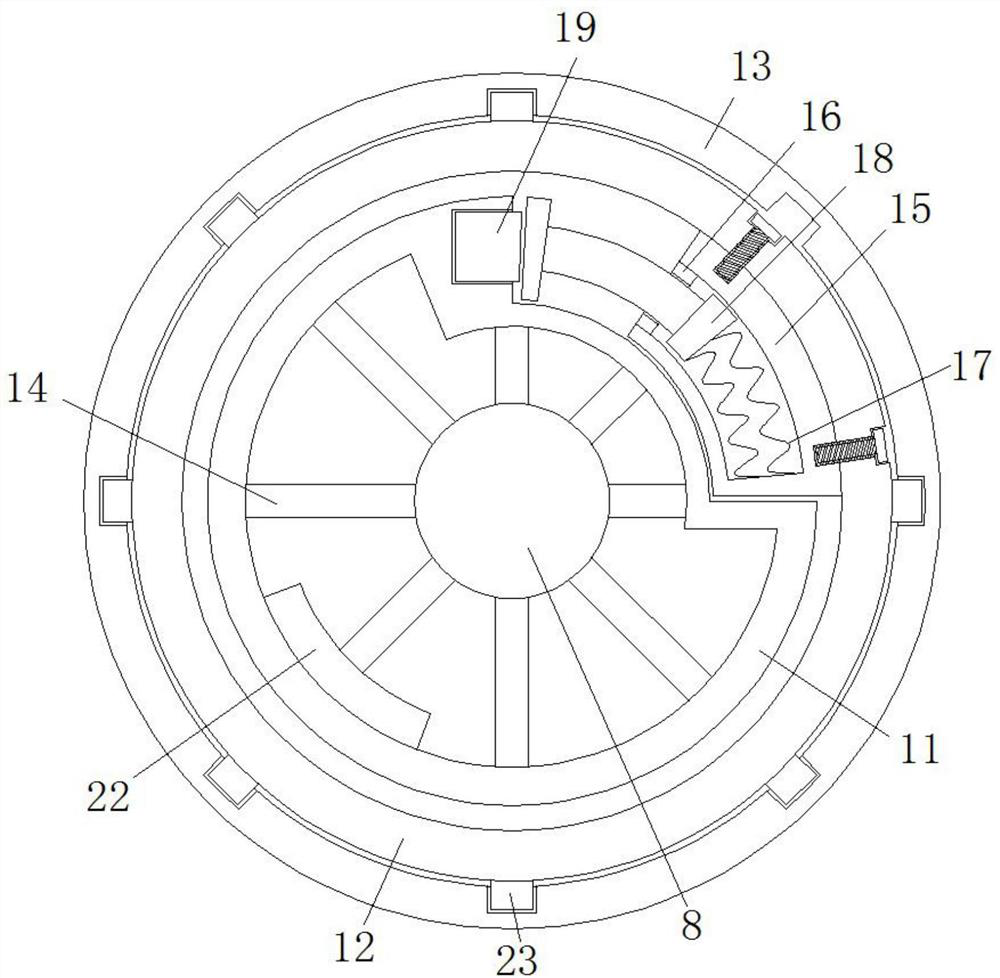

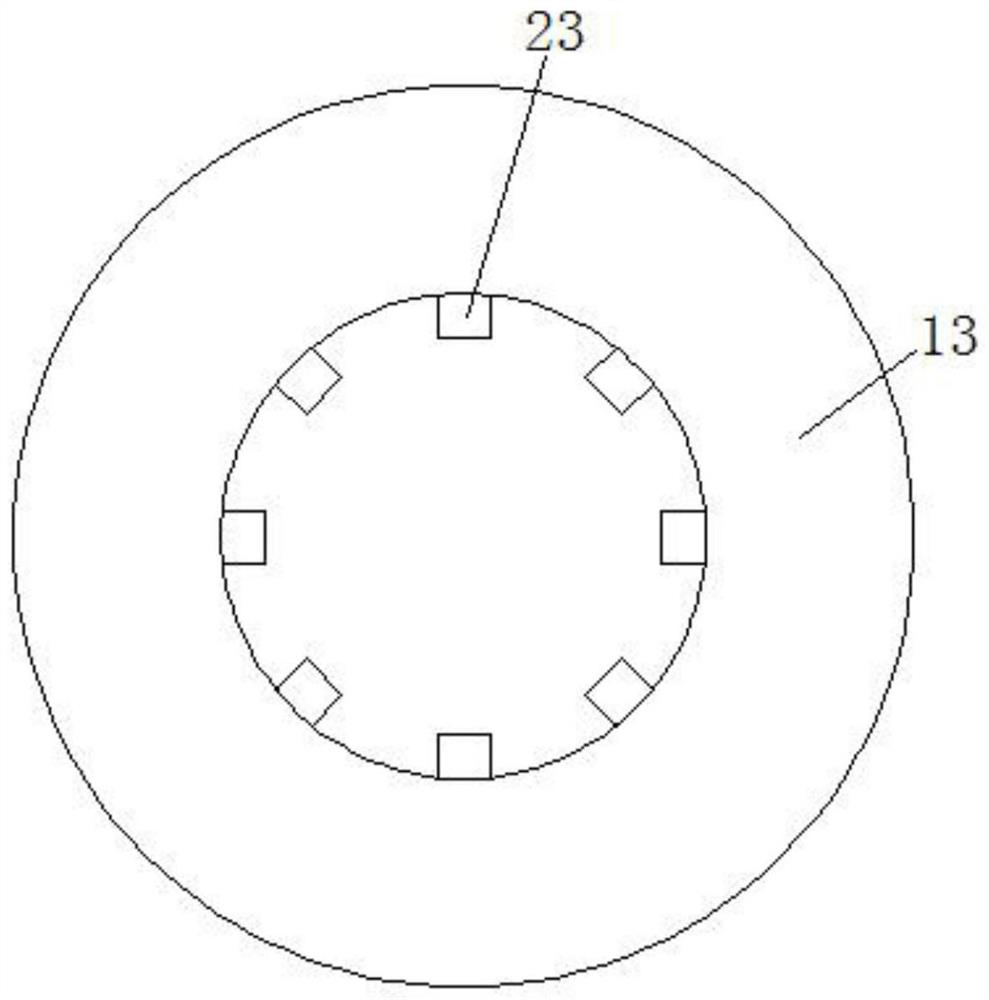

[0022] refer to Figure 1-3 , comprising a track base 1, the top of the track base 1 is provided with a track groove, the top side of the track base 1 is provided with a track plate one 2 and a track plate two 3, the track plate one 2 and the track plate two 3 are arranged side by side, and the track plate one 2 and the track plate two 3 are provided with a fixed pin 5, one side of the track base 1 is fixed with a reciprocating cylinder 6 by bolts, the reciprocating cylinder 6 is horizontally arranged, and the output rod of the reciprocating cylinder 6 is connected to one side of the track plate one 2 Fixedly connected, the top sides of track plate 1 2 and track plate 2 3 are connected with a rotating seat 7, and a rotating seat 7 is connected with a connecting rod 8, and the other rotating seat 7 is connected with an I-shaped rotating seat 7. Part 9, one end of the connecting rod 8 extends to one side of the rotating seat 7 and is fixedly connected with a rotating gear plate ...

Embodiment 2

[0025] Such as Figure 1-3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, several fixing rods 14 are fixedly welded between the connecting rod 8 and the inner cylinder 11, and the fixing rods 14 are arranged divergently.

[0026] In this embodiment, the connecting rod 14 is used to prevent the diameter of the connecting rod 8 from being too large, thereby reducing weight and saving energy.

Embodiment 3

[0028] Such as Figure 1-3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a weight plate 22 is fixedly connected to the inner wall of the outer cylinder 12 away from the groove.

[0029] In this embodiment, the masses on both sides of the connecting rod 8 are similar, and the rotation is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com