Damping device

A vibration-damping device, a technology for connecting position, applied in the direction of lifting device, accumulator device, fluid pressure actuating device, etc., can solve problems such as unfavorable unloading shock, and achieve the effect of opening and closing vibration reduction and mitigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

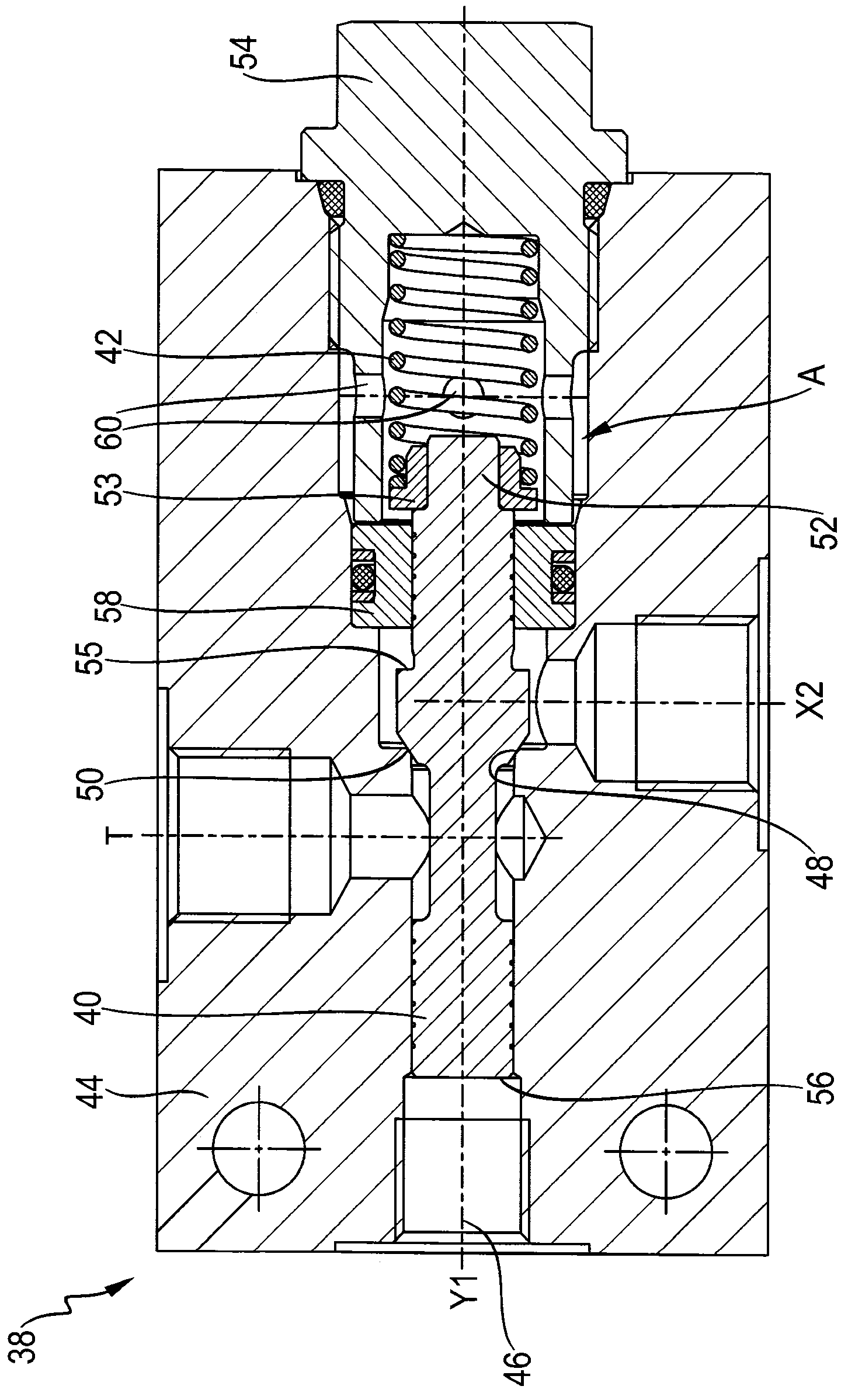

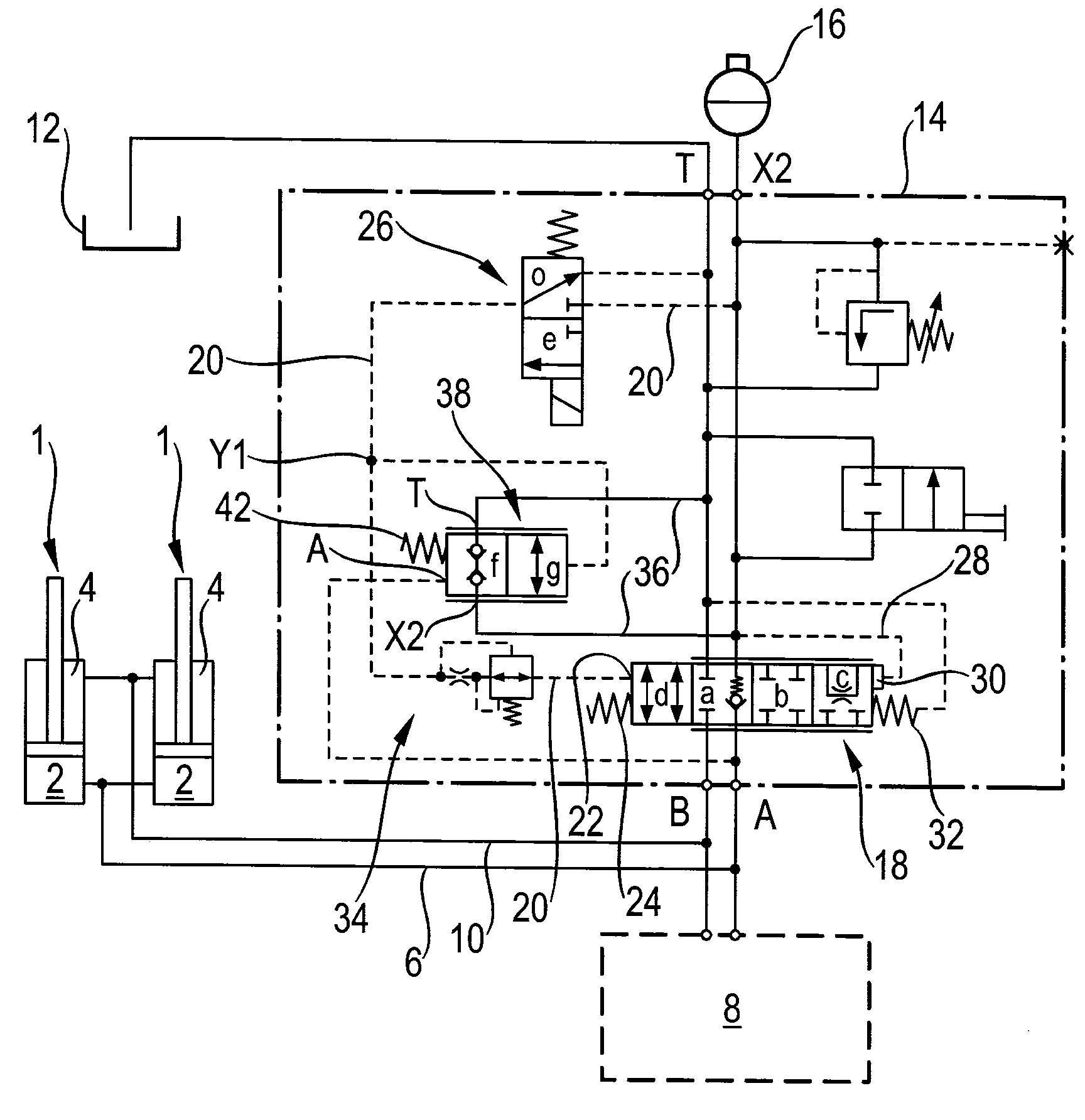

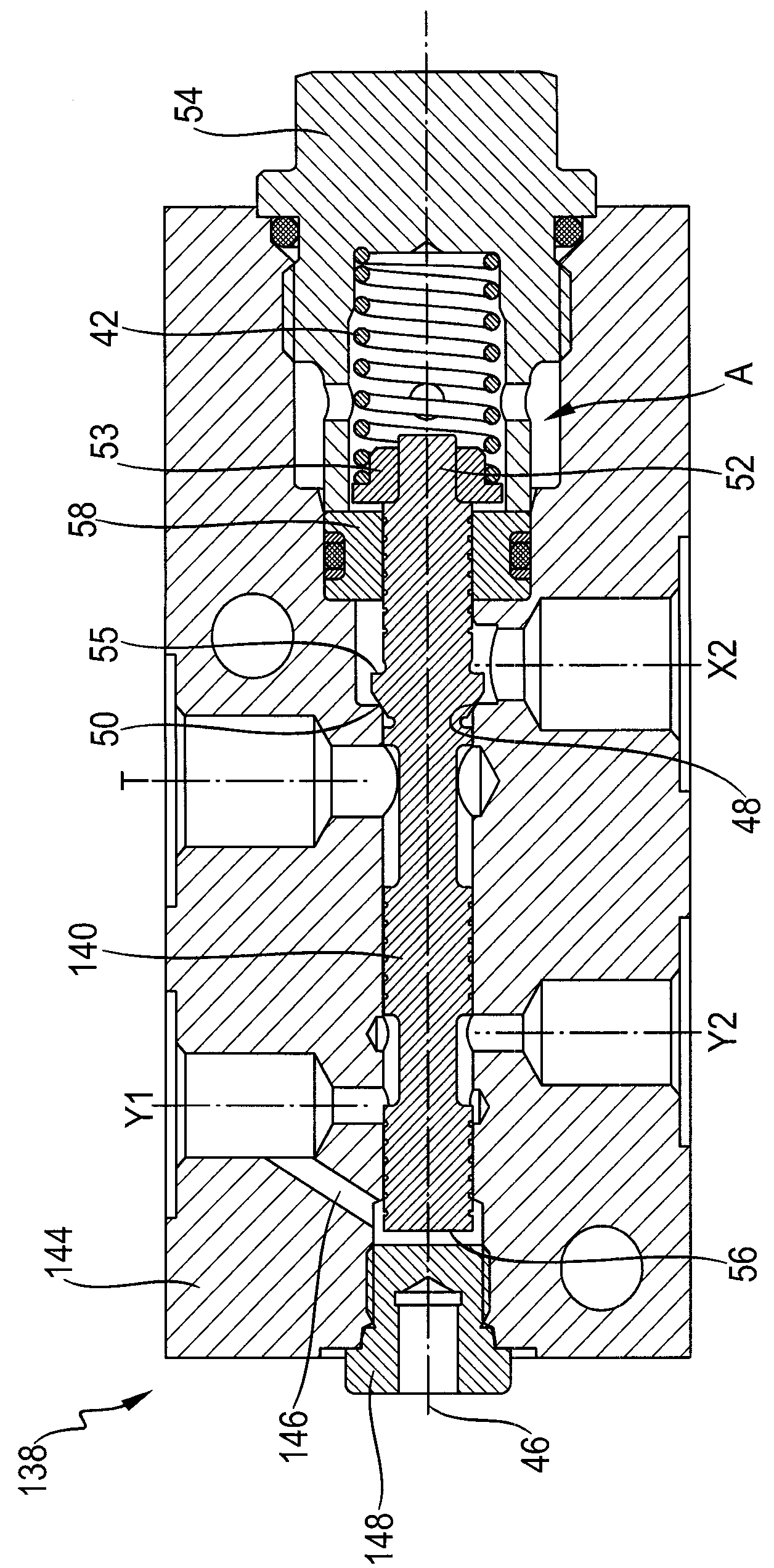

[0079] figure 1 A portion of the hydraulic circuit of a wheel loader is shown. It has two cooperating lifting cylinders 1 which are each designed as a differential cylinder and are used to lift the (not shown) shovel of the wheel loader. The lifting cylinder 1 has a bottom chamber 2 and an annular chamber 4 respectively, wherein the two bottom chambers 2 communicate with the control block 8 of the wheel loader via the first working line 6 and the two annular chambers 4 via the second working line 10 connect. This control block controls the supply of pressure medium to the two lifting cylinders 1 and thus controls the lifting movement of the shovel. Furthermore, the wheel loader has a storage box 12 .

[0080] Especially in the case of relatively rapid travel of the wheel loader (for example above 6 km / h) and especially when the shovel is filled, the hydraulic accumulator 16 can be connected via the vibration damping device 14 according to the invention to the following On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com