Cable dragging device for mining machinery

A tractor and mechanical technology, used in transportation and packaging, thin material handling, and conveying filamentous materials, etc., can solve the problems of adjustment of the winding device, inconvenient winding, and large limitations, so as to prolong the service life and improve the Practicality, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

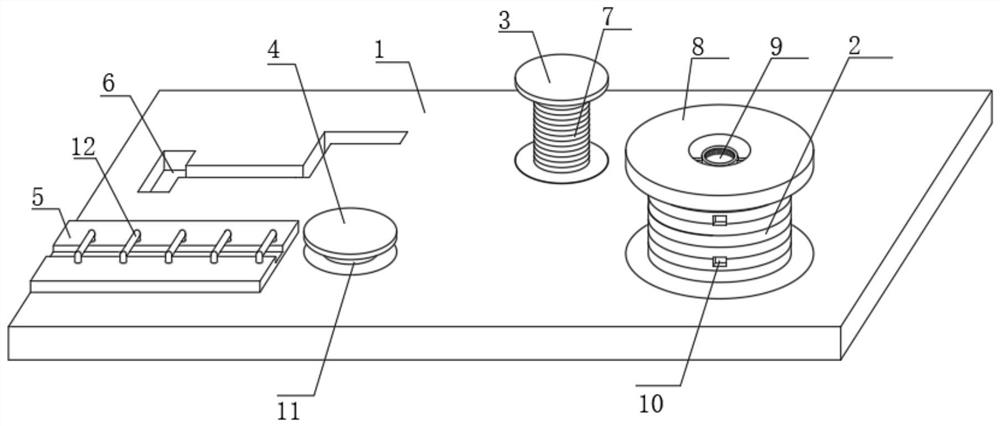

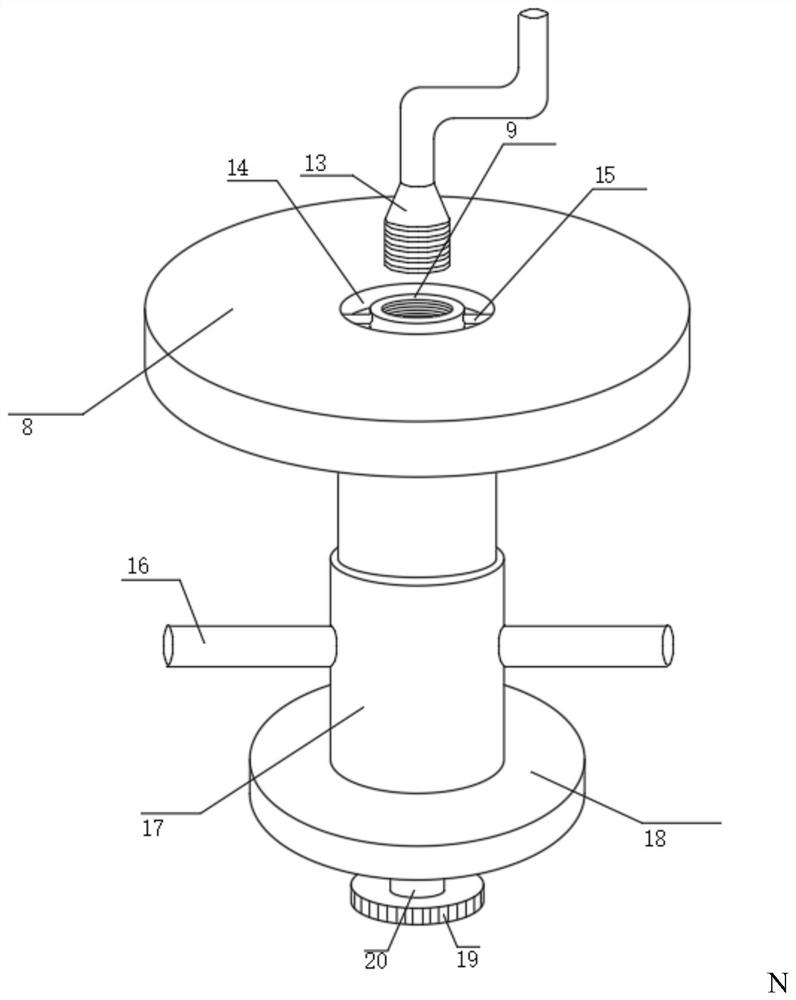

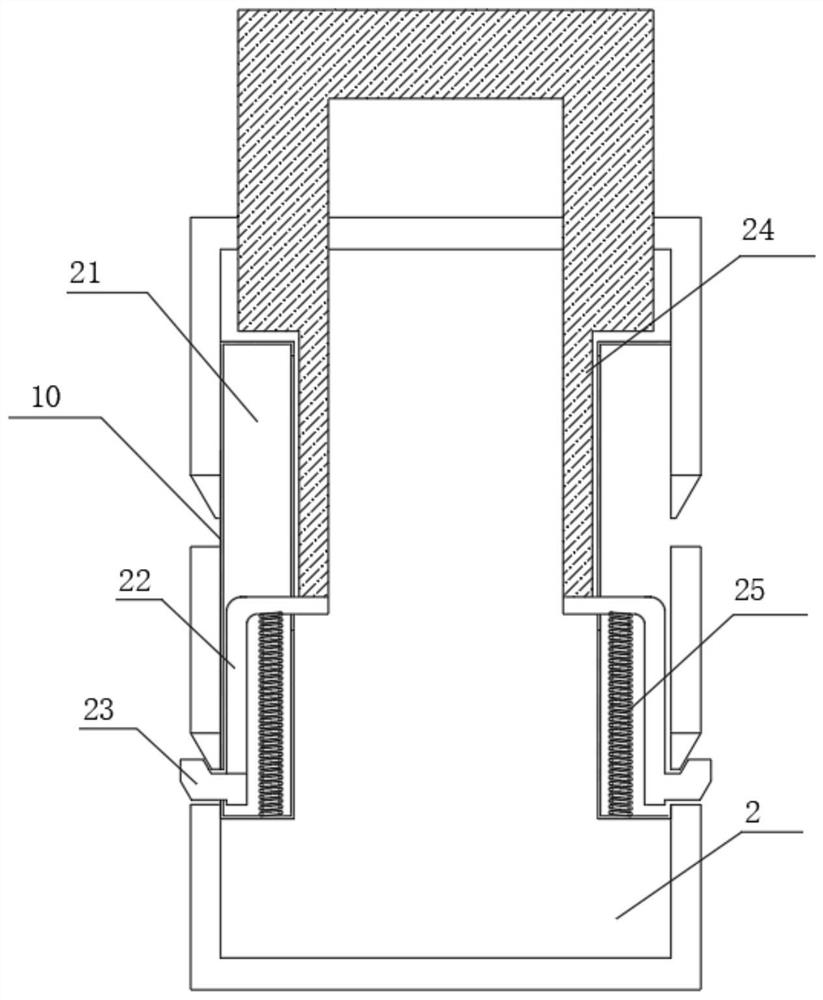

[0024] Embodiment 1. A cable pulling device for mining machinery, including a floor 1, the surface of the floor 1 is provided with a handle groove 6, and the surface of the floor 1 is fixedly installed with a wire plate 5, a second limiter 4 and a first limiter. The surface of the spacer 3 floor 1 is movably installed with a take-up assembly 2, the surface of the guide plate 5 is provided with a limit cavity 28, the upper surface of the lead plate 5 is fixedly installed with a clamp 12, and the bottom of the limit cavity 28 is fixedly installed with a rubber strip 26. A return spring 29 is fixedly installed on the inner wall of the clip 12, and the other end of the return spring 29 is fixedly connected with a block 30. A baffle 8 is installed on the top of the take-up assembly 2, and a card slot 14 is opened in the middle of the baffle 8. The inner wall of the card slot 14 is fixedly connected with the linkage rod 15, and the other end of the linkage rod 15 is fixedly connected...

Embodiment 2

[0037] Embodiment 2. A cable pulling device for mining machinery, including a floor 1, the surface of the floor 1 is provided with a handle groove 6, and the surface of the floor 1 is fixedly installed with a wire plate 5, a second limiter 4 and a first limiter. The surface of the spacer 3 floor 1 is movably installed with a take-up assembly 2, the surface of the guide plate 5 is provided with a limit cavity 28, the upper surface of the lead plate 5 is fixedly installed with a clamp 12, and the bottom of the limit cavity 28 is fixedly installed with a rubber strip 26. A return spring 29 is fixedly installed on the inner wall of the clip 12, and the other end of the return spring 29 is fixedly connected with a block 30. A baffle 8 is installed on the top of the take-up assembly 2, and a card slot 14 is opened in the middle of the baffle 8. The inner wall of the card slot 14 is fixedly connected with the linkage rod 15, and the other end of the linkage rod 15 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com