Soft cone spooling process applied to dyeing of cones of viscose filament yarns

A viscose filament, winding process technology, applied in the field of loose winding dyeing, can solve the problems of uneven dyeing, the bulk density cannot meet the dyeing requirements, etc., and achieves high spinnability, moderate bulk density, Increase the effect of the adaptation surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

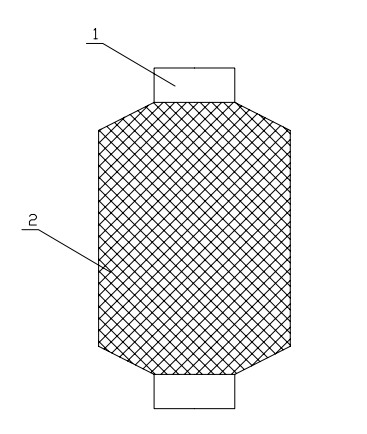

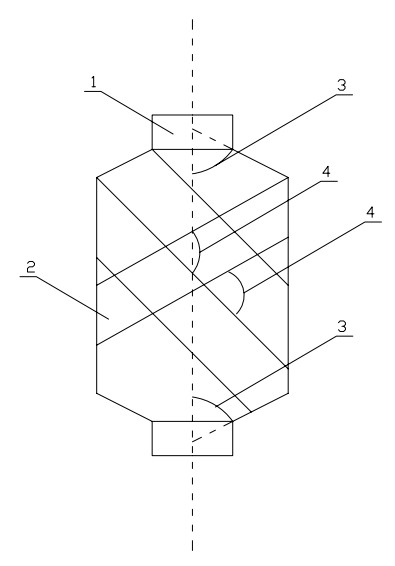

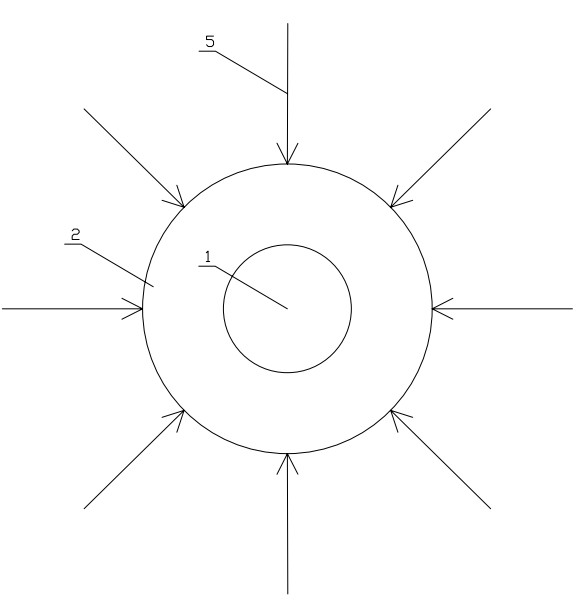

[0033]A loose tube winding process suitable for loose tube dyeing of viscose filaments, characterized in that the viscose filaments are divided into inner layer viscose filaments, middle layer viscose filaments, outer layer viscose filaments through a loose tube winding machine Three layers of viscose filaments are wound on the loose tube to form a loose tube. The slope of the end face of the loose tube is 50°. When winding, the cross angle of the viscose filaments is 6°. The loose tube is wound The pressure of the winding arm on the machine perpendicular to the guide roller is 150g, and the density of viscose filaments on the loose tube after the loose tube is formed is 0.3g / cm 3 .

Embodiment 2

[0035] A loose tube winding process suitable for loose tube dyeing of viscose filaments, characterized in that the viscose filaments are divided into inner layer viscose filaments, middle layer viscose filaments, outer layer viscose filaments through a loose tube winding machine Three layers of viscose filament are wound on the loose tube to form a loose tube. The slope of the end face of the loose tube is 90°. When winding, the crossing angle of the viscose filament is 18°. The loose tube is wound The pressure of the winding arm on the machine perpendicular to the guide roller is 800g, and the density of the viscose filaments on the loose tube after the loose tube is formed is 0.5g / cm 3 .

Embodiment 3

[0037] A loose tube winding process suitable for loose tube dyeing of viscose filaments, characterized in that the viscose filaments are divided into inner layer viscose filaments, middle layer viscose filaments, outer layer viscose filaments through a loose tube winding machine Three layers of viscose filaments are wound on the loose tube to form a loose tube. The slope of the end face of the loose tube is 70°. When winding, the crossing angle of the viscose filaments is 12°. The loose tube is wound The pressure of the winding arm on the machine perpendicular to the guide roller is 475g, and the density of viscose filaments on the loose tube after the loose tube is formed is 0.4g / cm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com