Production method of sandwich-like structure solid polymer electrolyte membrane, and application of sandwich-like structure solid polymer electrolyte membrane in solid-state lithium ion battery

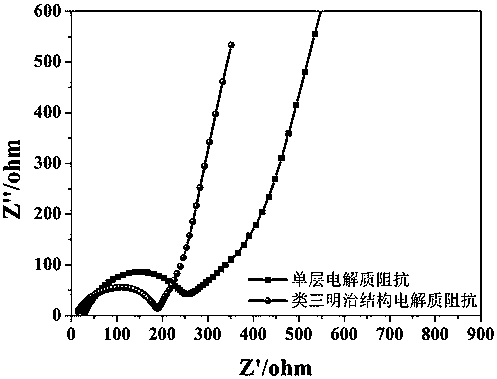

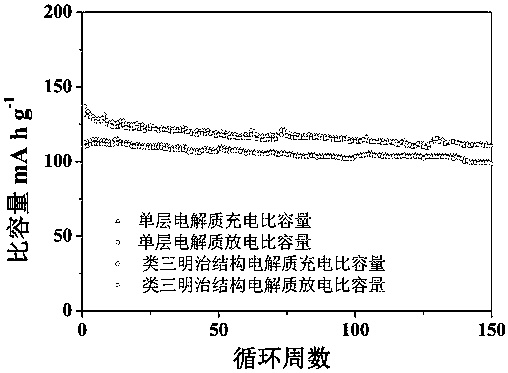

A solid polymer and lithium-ion battery technology, applied in electrolytes, secondary batteries, structural parts, etc., can solve problems such as poor mechanical properties, low electrical conductivity, high interface impedance, etc., to increase mechanical properties and improve lithium ion conductivity The effect of reducing the contact internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Preparation of positive electrode sheet:

[0019] According to the mass percentage of 80:10:10, the positive electrode active material lithium iron phosphate, the conductive agent acetylene black and the binder PPC are added to an appropriate amount of anhydrous acetonitrile, stirred and mixed evenly to prepare a slurry and coated on an aluminum foil, and then It was dried in an oven at 40° C. for 30 minutes, and then dried in a vacuum oven at 80° C. for 24 hours to obtain a lithium iron phosphate positive electrode sheet.

[0020] Preparation of sandwich-like solid polymer electrolyte membrane:

[0021] Dissolve 1g of PPC and 0.5g of alkali metal salt LiTFSI in an appropriate amount of acetonitrile, stir and mix uniformly to obtain solution A; take half of solution A and add 0.2g plasticizer SN to it, fully stir and mix uniformly to obtain solution B; The two sides were coated with solution A and solution B respectively, and dried in a vacuum oven for 12 hours to obta...

Embodiment 2

[0027] Preparation of positive electrode sheet:

[0028] According to the mass percentage of 70:10:20, the positive electrode active material nickel cobalt manganese, the conductive agent acetylene black and the binder PEO are added to an appropriate amount of anhydrous acetonitrile, stirred and mixed evenly to prepare a slurry and coated on an aluminum foil, and then It was dried in an oven at 40° C. for 30 minutes, and then dried in a vacuum oven at 80° C. for 24 hours to obtain a positive electrode sheet of nickel cobalt lithium manganese oxide.

[0029] Preparation of sandwich-like solid polymer electrolyte membrane:

[0030] Dissolve 1g of PEO and 0.17g of alkali metal salt LiTFSI in an appropriate amount of acetonitrile, stir and mix uniformly to obtain solution A; take half of solution A and add 0.6g plasticizer SN to it, fully stir and mix uniformly to obtain solution B; Both sides of the fiber membrane were coated with solution A and solution B, and dried in a vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com