Compound for anode material of lithium ion secondary battery and preparation method thereof

A secondary battery and negative electrode material technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve problems such as unsuitable for industrial production, affecting electrochemical performance, complicated process, etc., and achieves significant practical value and good performance. Industrial application prospect, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

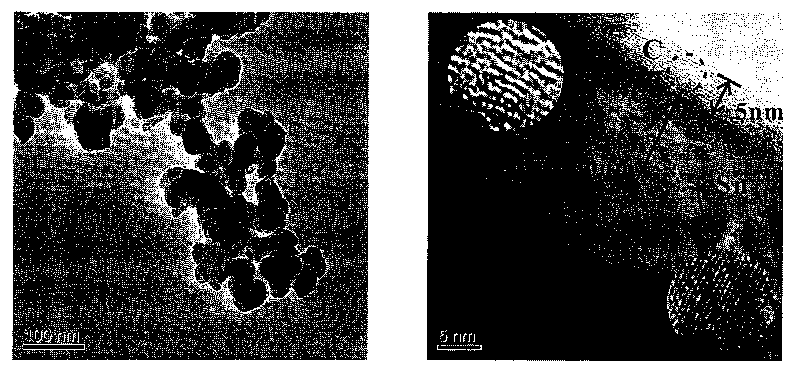

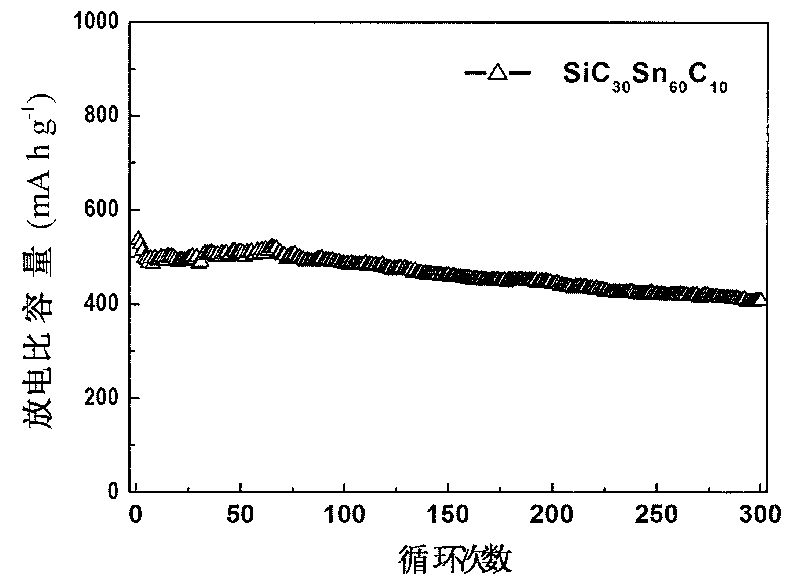

[0033] Mix 1.4g (1.2g) Sn powder and 0.4g (0.6g) nano-SiC powder evenly, ball mill for 20h under the protection of high-purity argon, cool to room temperature naturally, take out the product and mix with 0.2g graphite. Under the protection of high-purity argon, the planetary ball milled for 6 hours, and after cooling to room temperature naturally, the ball mill jar was opened under an inert atmosphere, and the target product SiC was obtained. 20 sn 70 C 10 (SiC 30 sn 60 C 10 ). Obtained SiC 20 sn 70 C 10 The TEM image of the composite material is shown in figure 1 shown; the resulting SiC 30 sn 60 C10 The cycle performance of composite materials such as figure 2 shown.

[0034] From figure 1 From the picture on the left, it can be seen that the material synthesized by this method has a uniform and regular near-spherical structure, with a particle size of 60-70nm and a uniform distribution; from the picture on the right, it can be seen that each spherical particle...

Embodiment 2

[0037] Mix 1.4g of Sb powder and 0.4g of nano-SiC powder evenly, perform high-energy ball milling for 20h under the protection of high-purity argon, and cool to room temperature naturally, then take out the product and mix with 0.2g of graphite. Under the protection of high-purity argon, the planetary ball milled for 6 hours, and after naturally cooling to room temperature, the ball mill jar was opened under an inert atmosphere to obtain the target product SiC 20 Sb 70 C 10 .

[0038] The resulting composite material at 100mA g -1 The reversible capacity in the first week under the current density is 590mAh g -1 , after 160 cycles, the capacity retention rate was 70%.

Embodiment 3

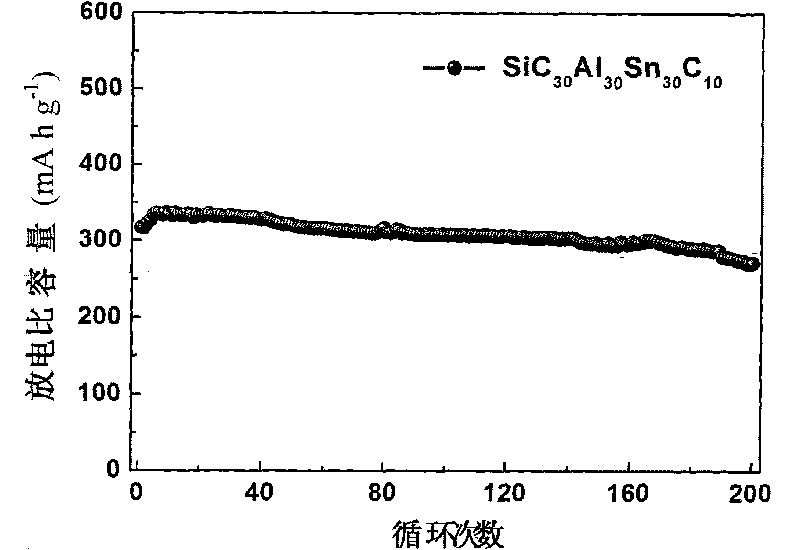

[0040] Mix 0.6g Sn powder, 0.6g Al powder, and 0.6g nano-SiC powder evenly, and high-energy ball mill for 20h under the protection of high-purity argon. After cooling to room temperature naturally, take out the product and mix with 0.2g graphite. Under the protection of high-purity argon, the planetary ball milled for 6 hours, and after naturally cooling to room temperature, the ball mill jar was opened under an inert atmosphere to obtain the target product SiC 30 Al 30 sn 30 C 10 . The cyclability of the resulting product composites is as image 3 .

[0041] From image 3 It can be seen that the resulting composite exhibits excellent electrochemical performance, with 100 mAg -1 The reversible capacity in the first week under the current density is 318mAhg -1 , after 200 cycles, the capacity retention rate is higher than 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com