Sandwich plate forming machine

A sheet forming machine and interlayer technology, applied in the directions of lamination, layered products, lamination devices, etc., can solve the problem of inability to produce qualified PVB film laminated glass products, and achieve lower production costs, lower equipment investment, and energy savings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

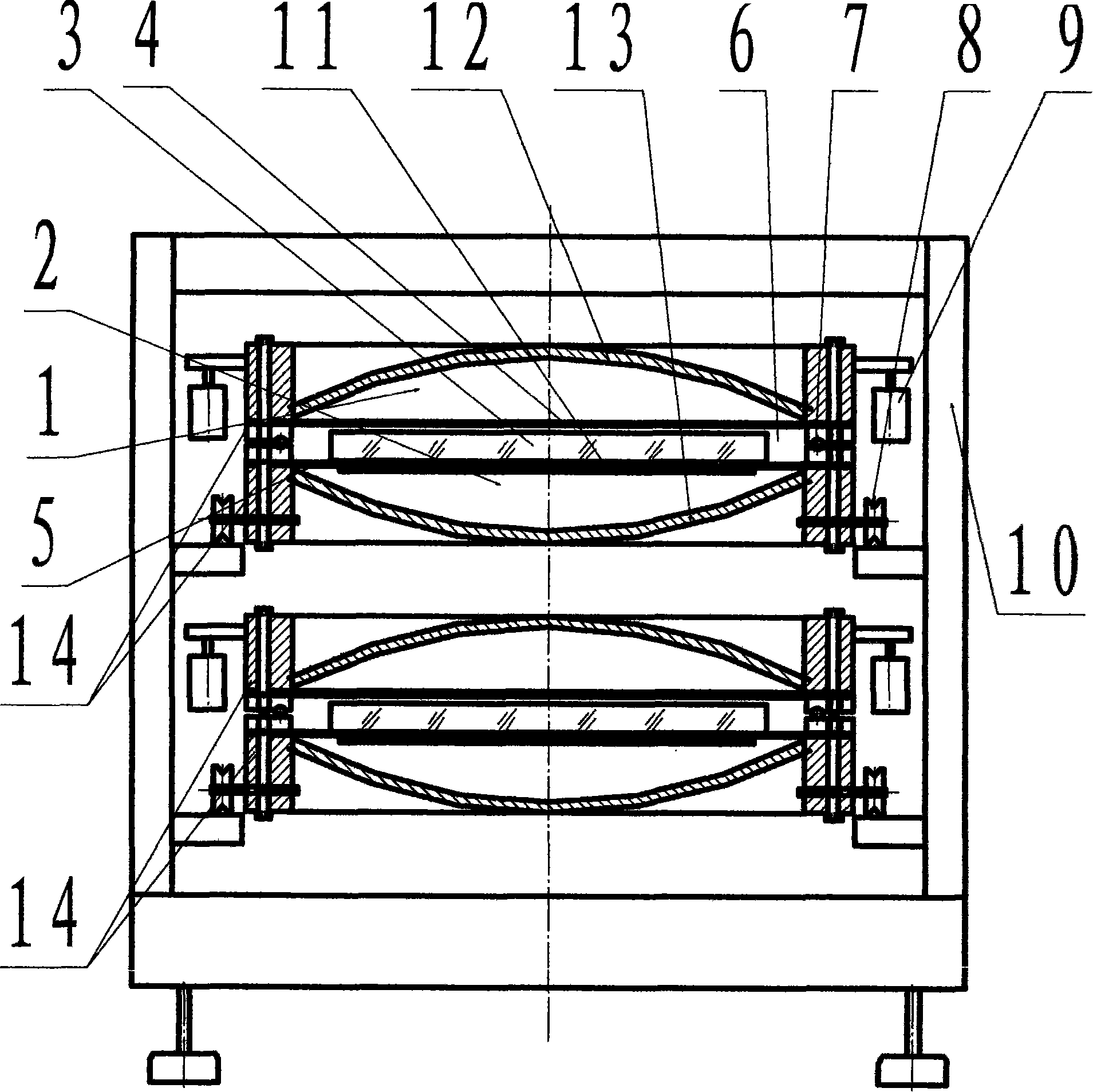

[0011] Referring to the accompanying drawings, the present invention will be further described.

[0012] As shown in the structure diagram of the present invention in Fig. 1, the present invention provides a kind of sandwich panel forming machine, and the complete machine mainly consists of an upper vacuum chamber 1, an upper vacuum chamber partition 4, an upper vacuum chamber top plate 12, a middle vacuum chamber 6, a lower vacuum chamber The vacuum chamber partition 5, the lower vacuum chamber 2, the lower vacuum chamber top plate 13, the sealing rubber strip 7, the sheet electric heating plate 11, the drawer-type multi-layer independent working assembly 14 structure, and the electronic measurement control device. The upper vacuum chamber partition 4 and the lower vacuum chamber partition 5 are rubber plates. The sheet-shaped electric heating plate 11 is placed on the lower part of the lower vacuum chamber partition plate 5 . A middle vacuum chamber 6 is formed between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com