All fiber Q-switch

An all-fiber, switching technology, applied in the field of Q-switching, can solve the problems of Q-switched fiber laser not working normally, device performance cannot be guaranteed, limited application range, etc., to achieve stable and reliable laser output, improve laser output power and efficiency, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

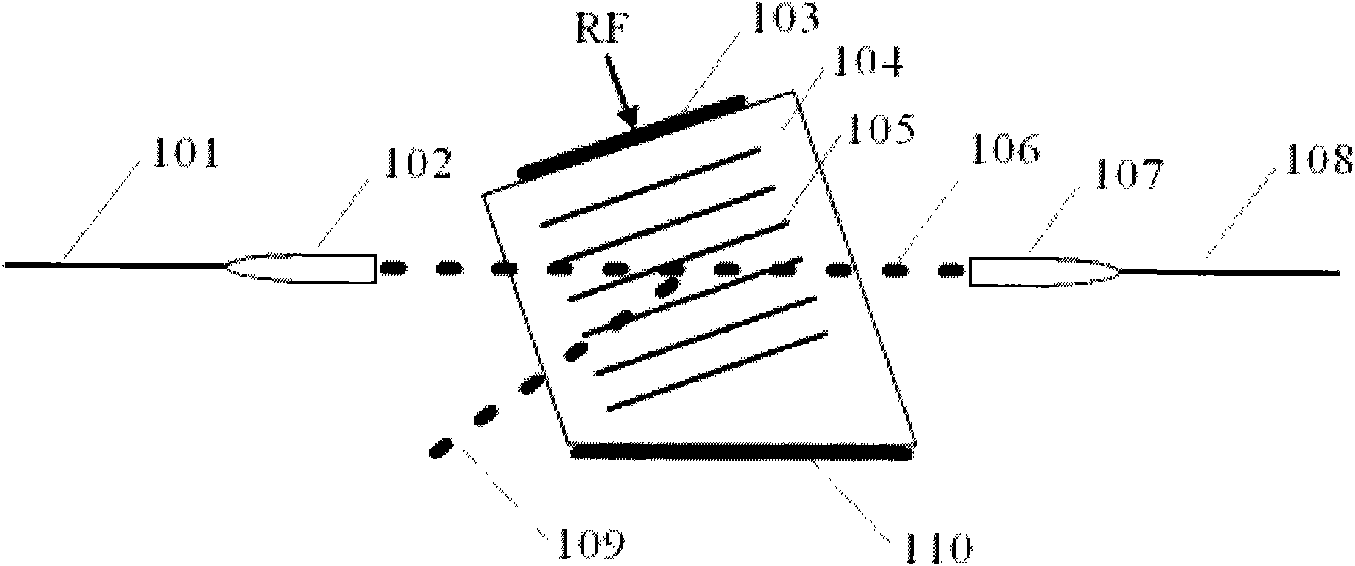

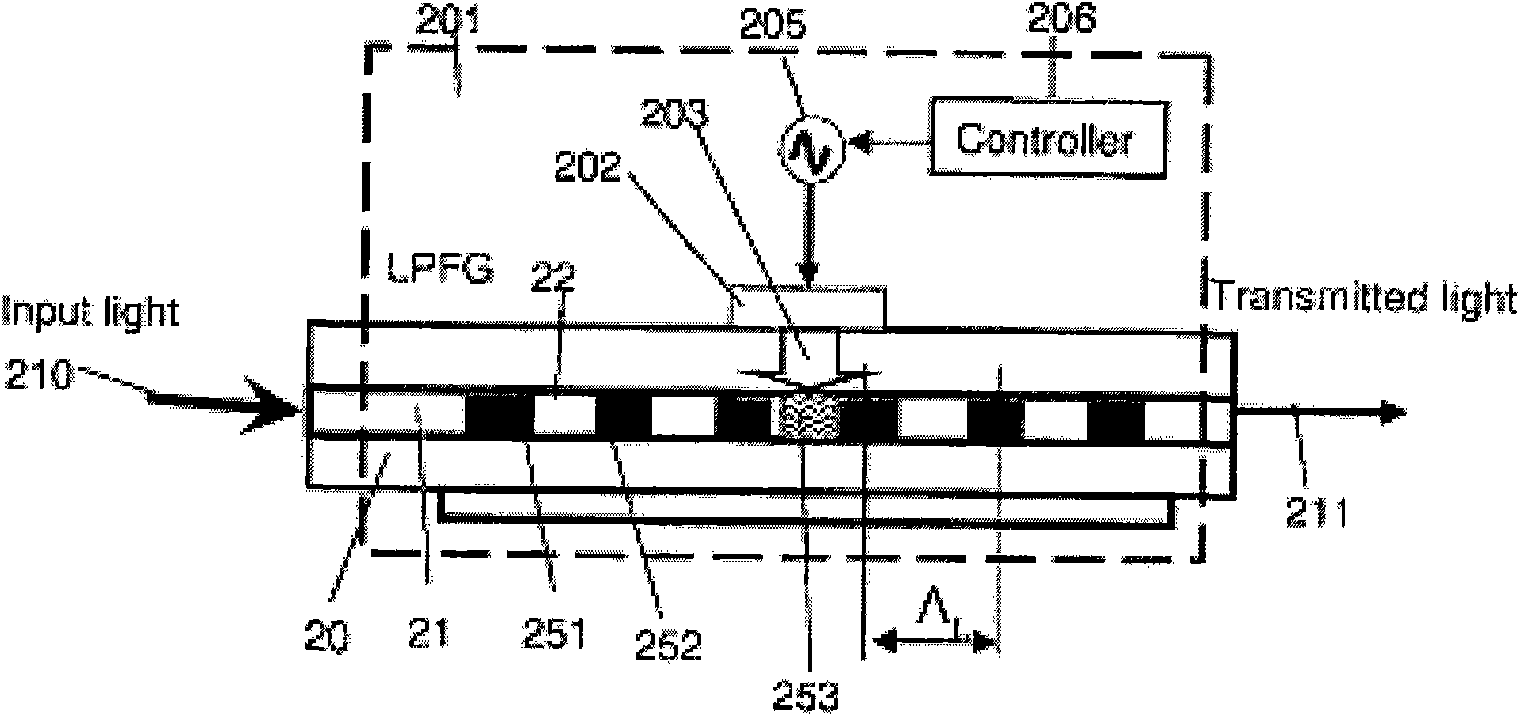

[0076] Figure 3a , Figure 3b It is a schematic diagram of the axial and transverse sections of the all-fiber Q-switch embodiment of the present invention. In this embodiment, the all-fiber Q-switch is composed of long-period grating pressing template 306, V-groove 310, optical fiber, piezoelectric ceramic 305, semiconductor cooling chip 312, thermistor 311, metal shell 304 and other components.

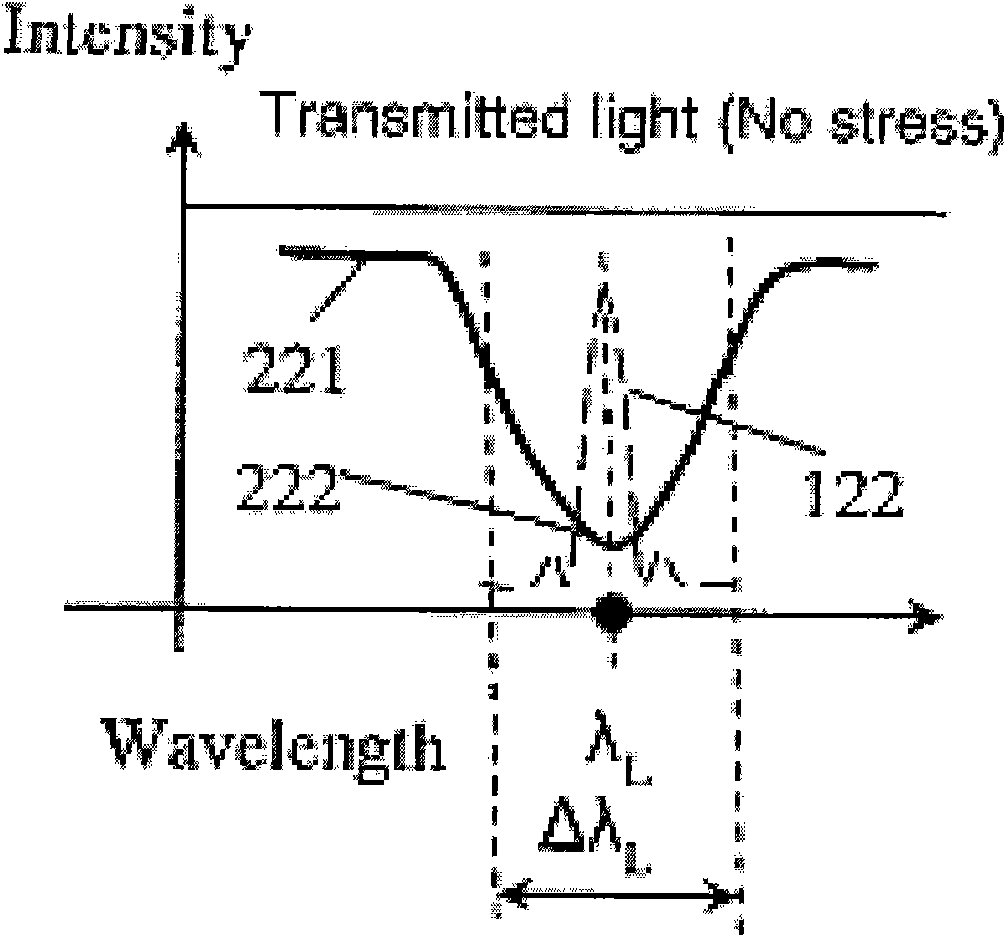

[0077] In this embodiment, the cross section of the V-shaped groove is as attached Figure 4 As shown, there is a V-shaped groove 402 in the center of the upper surface of the V-shaped groove base material 401, which has a cross section like the letter "V". The length of the V-groove is 3 cm, and the depth of the V-groove is 100 μm. The axial section of the long-period grating pressing template is attached Figure 5 As shown, the lower surface of the LPFG pressing template base material 501 has a tooth-like surface feature 502 with a period of 206 microns in the lateral directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com