Method for preparing sandwich-like Ce: YAG glass-ceramic sheet by tape casting method

A glass-ceramic and sandwich technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as not involved, and achieve the effects of reducing direct contact, low melting point, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

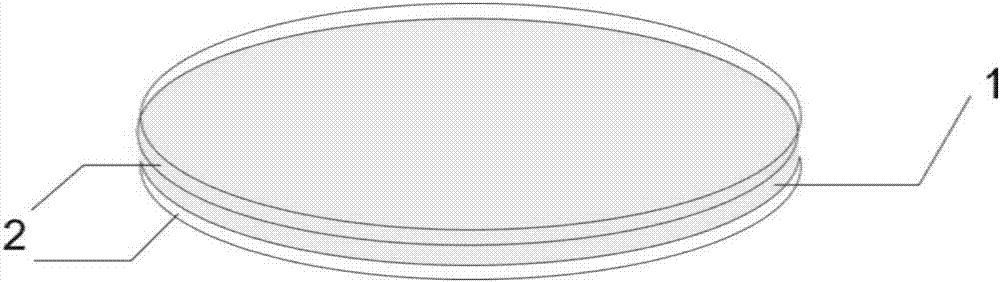

Embodiment 1

[0036] Will analyze pure ZnO, Sb 2 O 3 , Te 2 0, Li 2 0, K 2 O, Ce: YAG, press 12ZnO: 17Sb 2 O 3 :37Te 2 0:6Li 2 0:13K 2 The ratio of O:15Ce:YAG phosphor (molar ratio) is accurately weighed and placed in an agate mortar. The mixture is mixed and ground in the agate mortar with distilled water according to the mass ratio of 94:6 to prepare a slurry , Spread evenly on the K9 wafer glass sheet with a size of Φ50*3mm with a casting machine, set 0.2mm as the thickness of the casting blade, and control the casting speed to 0.04m / s, and dry at 200℃ in vacuum Dry in the box for 6 hours, cool and take it out. Cover the surface of the mixture with a Φ50*3mm K9 wafer glass sheet. The sandwich-shaped glass clip is placed in a resistance furnace and heated to 650°C for 1 hour, and then cooled with the furnace A transparent, low-melting, 6.2mm thick, sandwich-like glass-ceramic wafer model sheet with a transmittance of 72% is formed at 20°C (attached figure 1 ). Such as figure 1 As shown, th...

Embodiment 2

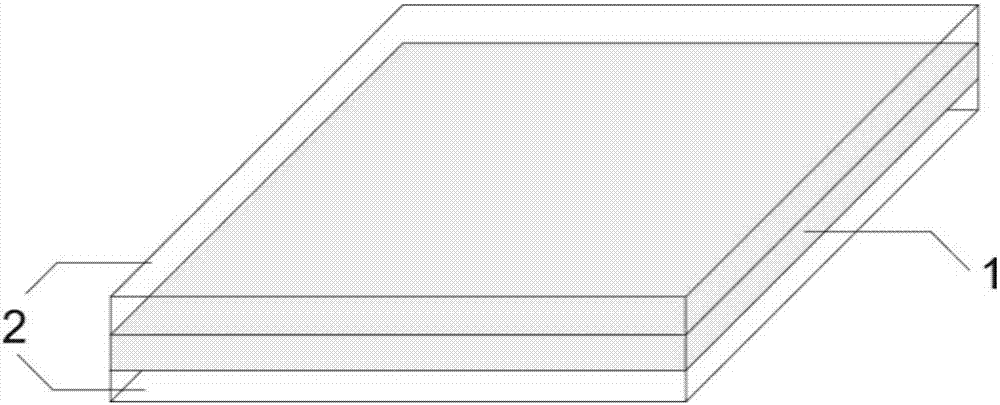

[0039] Will analyze pure ZnO, Sb 2 O 3 , Te 2 0, Li 2 0, K 2 O, Ce: YAG, press 16ZnO: 15Sb 2 O 3 :35Te 2 0:6Li 2 0:13K 2 O:15

[0040] The ratio of Ce:YAG phosphor (molar ratio) is accurately weighed and placed in an agate mortar. The mixture obtained after mixing and grinding in the agate mortar is mixed with distilled water according to the mass ratio of 94:6 to prepare a slurry. The casting machine is evenly coated on a 50*50mm square K9 white glass sheet, the spiral micrometer is set to 0.3mm as the thickness of the casting blade, and the casting speed is controlled to 0.04m / s. Dry for 6 hours in a vacuum drying oven at 200°C, cool and take out the cover sheet, directly put it in a resistance furnace, heat it to 620°C and keep it for 1 hour, then cool it down to 20°C to form a transparent low melting point with a thickness of 6.3mm and transparent Sandwich-shaped glass-ceramic square slices with a rate of 69% (attached image 3 ). Such as image 3 As shown, the glass-ceramic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com