Production of solid pump for discharge light with low pressure gas

A gas discharge lamp, low pressure technology, applied in the parts of gas discharge lamps, the manufacture of discharge tubes/lamps, the manufacture of electrode systems, etc., can solve the problem of particle weight, size and shape consistency, uneven composition, harmful to environmental protection and personal health and other issues, to achieve the effect of high one-time pass rate, low production cost and good photoelectric parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

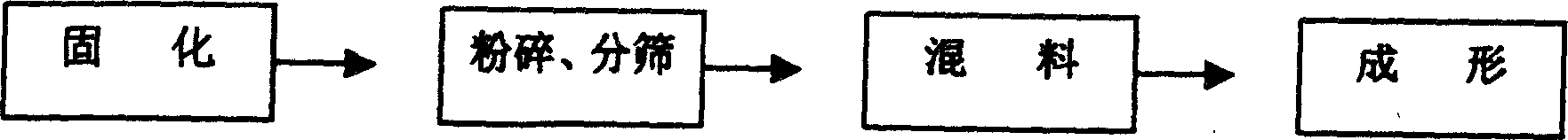

Method used

Image

Examples

Embodiment 1

[0008] Example 1: Solidification is the solidification of two metal powders and mercury, and mixing is the mixing of two metals in the form of amalgam and one metal. Mix Hg, Zn powder, and Bi powder in a weight ratio of 45:43:12 and place them in a closed tank, vacuumize, fill with 20 torr high-purity argon, heat to 180°C, and keep warm for 1.0 hour to obtain the Zn powder and Bi powder in the form of amalgam are added with 1% Ag powder by weight of the amalgam powder, fully mixed and pressed into a cylinder. The solid mercury is used to replace liquid mercury in various exposed fluorescent lamps such as fluorescent lamps, ring fluorescent lamps, and compact fluorescent lamps. It has good low-temperature starting performance of liquid mercury, and better high-temperature performance than liquid mercury. Zn-Hg alloy, because the addition of Bi reduces the amount of residual mercury that Zn-Hg alloy cannot completely release at normal working temperature.

Embodiment 2

[0009] Embodiment 2: solidification is a kind of metal powder, a kind of metal block and mercury melting and solidification, mixing is a kind of amalgam and a kind of metal are mixed. Mix Hg, Bi powder, and In blocks in a weight ratio of 6:63:31 and place them in a reactor, vacuumize, fill with 0.2MPa high-purity argon, heat to 200°C, keep warm for 2 hours, and melt to obtain Melt amalgam with 6% mercury, crush it into powder, add Ag powder with 1% by weight of Bi-In-Hg alloy, mix well, extrude and cut into cylinders, the melting temperature of this solid mercury is higher than that of Bi with 6% mercury -In-Hg is high, the particle surface is not easy to spill mercury.

Embodiment 3

[0010] Embodiment 3: Solidification is solidification of a metal alloy powder and mercury, and mixing is mixing an amalgam. Mix Bi-Sn alloy powder and mercury in a weight ratio of 90:10 and place in a closed tank, vacuumize, fill with 100 torr high-purity argon, heat to 90°C, and keep warm for 3 hours to obtain mercury-containing 10 % Bi-Sn-Hg amalgam powder, fully mixed, pressed into a sphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com