Container and platform floor with bamboo oriented structure shaving board as sandwich layer and manufacturing method thereof

A technology of carriage floor and particle board, applied in the field of carriage floor and its manufacture, and containers, which can solve the long and arduous and lost problems, and achieve the effect of low price, abundant resources and good pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

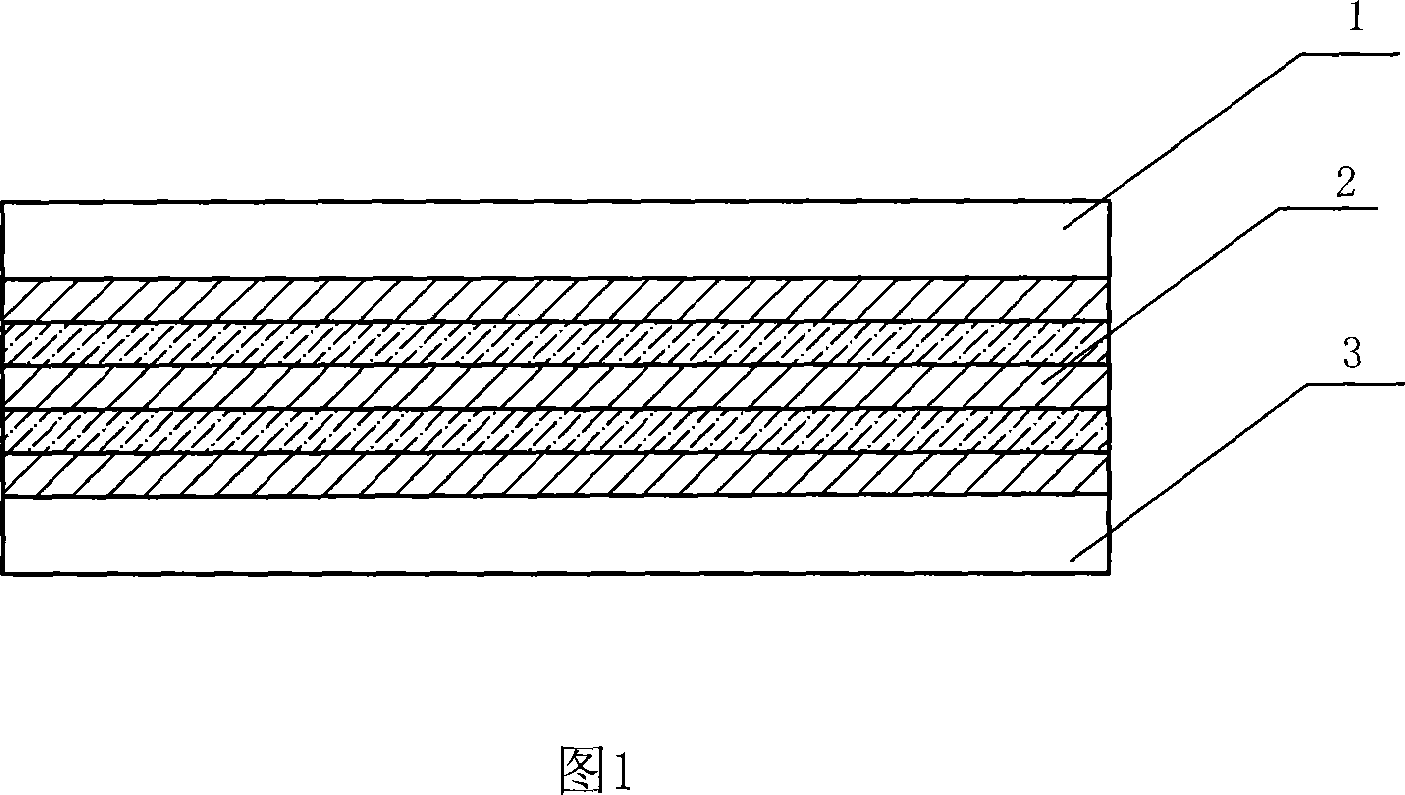

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] Bamboo oriented particle board is the core layer of the container and the bottom plate of the carriage. It is formed by bonding the three-layer structure of the surface layer 1, the core layer 2, and the bottom layer 3. The core layer 2 is five layers of bamboo shavings. Oriented strand board formed by combining, the surface layer 1 and the bottom layer 3 are composite layers of three layers of wood veneer and one layer of impregnated paper.

[0024] Among them, the surface layer and the bottom layer are made of cloned wood, and the wooden veneer is made of glue-coated, cloned wood or other hardwood veneers with a moisture content of less than 10% along the grain, which is bonded to the core layer after pre-pressing and hot-pressing. Then the impregnated paper is coated on the core substrate through a hot press on the surface and bottom.

[0025] Its production proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com