Device and method for producing self-excited II type anhydrous gypsum by utilizing industrial byproduct gypsum

A technology for industrial by-products of gypsum and anhydrous gypsum, which is applied in the field of comprehensive utilization industry and chemical gypsum recycling, and can solve the problems of inability to perform feedback control, inability to judge the quality of type II anhydrite, and inability to solve the problems of deep utilization of energy, etc. , to achieve energy saving, low free moisture, and reduced equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

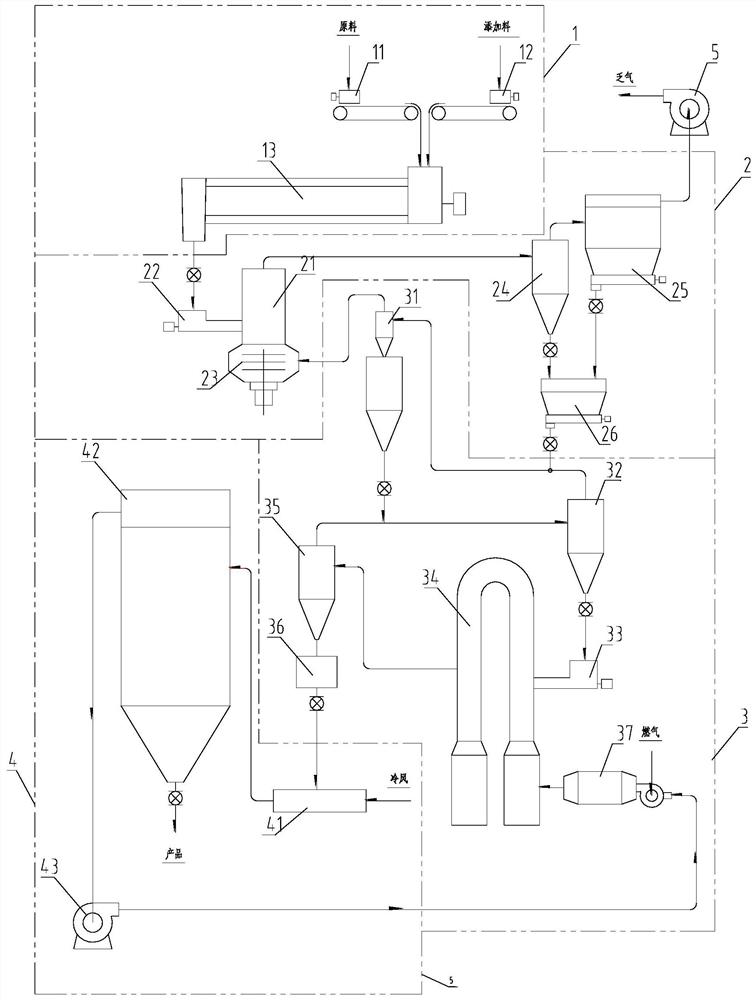

[0066] In this embodiment, a device for producing type II anhydrite by using industrial by-product gypsum, the schematic diagram of its structure is as follows figure 1 As shown, it includes two-stage dynamic calcination system 3, rotary flash drying system 2, industrial by-product gypsum pretreatment system 1, type II anhydrous gypsum cooling system 4 and system high-pressure induced draft fan 5 and pipeline system, industrial by-product gypsum Pretreatment system 1, spin flash drying system 2, two-stage dynamic calcination system 3 and type II anhydrite cooling system 4 are connected through pipelines in turn, and the system high-pressure induced draft fan 5 is connected to spin flash drying system 2, the specific systems The connection relationship between components is:

[0067] Both the raw material feeder 11 and the additive feeder 12 are connected to the stirring mixer 13, the stirring mixer 13 is connected to the spin flash dryer 21 through the dryer feeder 22, and the...

Embodiment 1-2

[0084] Same as Example 1-1, the difference is that the raw material is Yunnan Yuntianhua stock desulfurization gypsum, the main components are the same, and the raw material also includes H 2 SO 4 and H 3 PO 4 Waiting for waste, the pH value is 1.5, the gypsum is not washed, and the same amount of crystal lattice agent is directly added, and at the same time, a neutralizer-calcium oxide with a mass ratio of 0.8% of the stock gypsum is added; a standard test block is prepared for testing. The initial setting time is 104 minutes, the final setting time is 225 minutes, the compressive strength is 26MPa, and the flexural strength is 6MPa.

Embodiment 2

[0086] With embodiment 1, difference is:

[0087] The second step is to add a crystal lattice agent, which is composed of carbide slag and KAlSO 4 50% each, accounting for 2% of the mass of the dehydrated gypsum.

[0088] The fourth step is the standard test block test. The initial setting time is 79 minutes, the final setting time is 197 minutes, the compressive strength is 34MPa, the flexural strength is 9MPa, and the organic matter removal rate reaches over 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| curing time | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com