High-efficiency magnetic roasting boiling furnace

A magnetized roasting and boiling furnace technology, applied in fluidized bed furnaces, furnaces, furnace types, etc., can solve the problems of ash leakage into the air chamber, red slag discharge from the furnace, complicated process and control, etc. requirements, the effect of improving fluidization conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

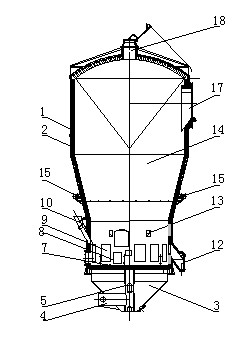

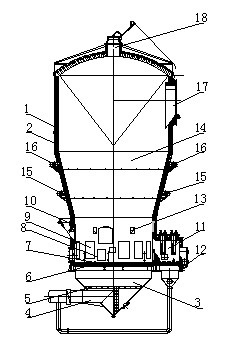

[0041]The present invention includes a casing, the casing is lined with an insulating layer 1 and a refractory layer 2, and the furnace body includes an air chamber 3 arranged in the lower part, an air distribution device arranged in the middle, a furnace arranged in the upper part, and a furnace cover located in the upper part of the furnace:

[0042] The air chamber 3: includes an air inlet pipe 4 and an air supply predistributor 5, and the air supply predistributor 5 is distributed on the entire cross section of the air chamber 3 in a grid shape.

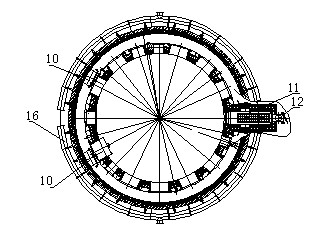

[0043] The air distribution device: includes a gas distribution device 6 and a high-density opening hood 7 arranged thereon, with a density of 80-100 pieces / m 2 .

[0044] The furnace: including the fluidized bed 8 arranged on the upper part of the gas distribution device 6, the middle expansion section and the upper furnace. The trough structure has an inclination angle of 33-36o, and the distance between the bottom of the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com