Combined aeration moving bed bio-membrane reactor

A moving bed biofilm and reactor technology, applied in the field of sewage treatment, can solve the problems of filler deposition at the bottom of the tank, dead angle, high energy consumption, etc., and achieve the effects of simple design of pipelines, guarantee of effluent water quality, and convenient operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

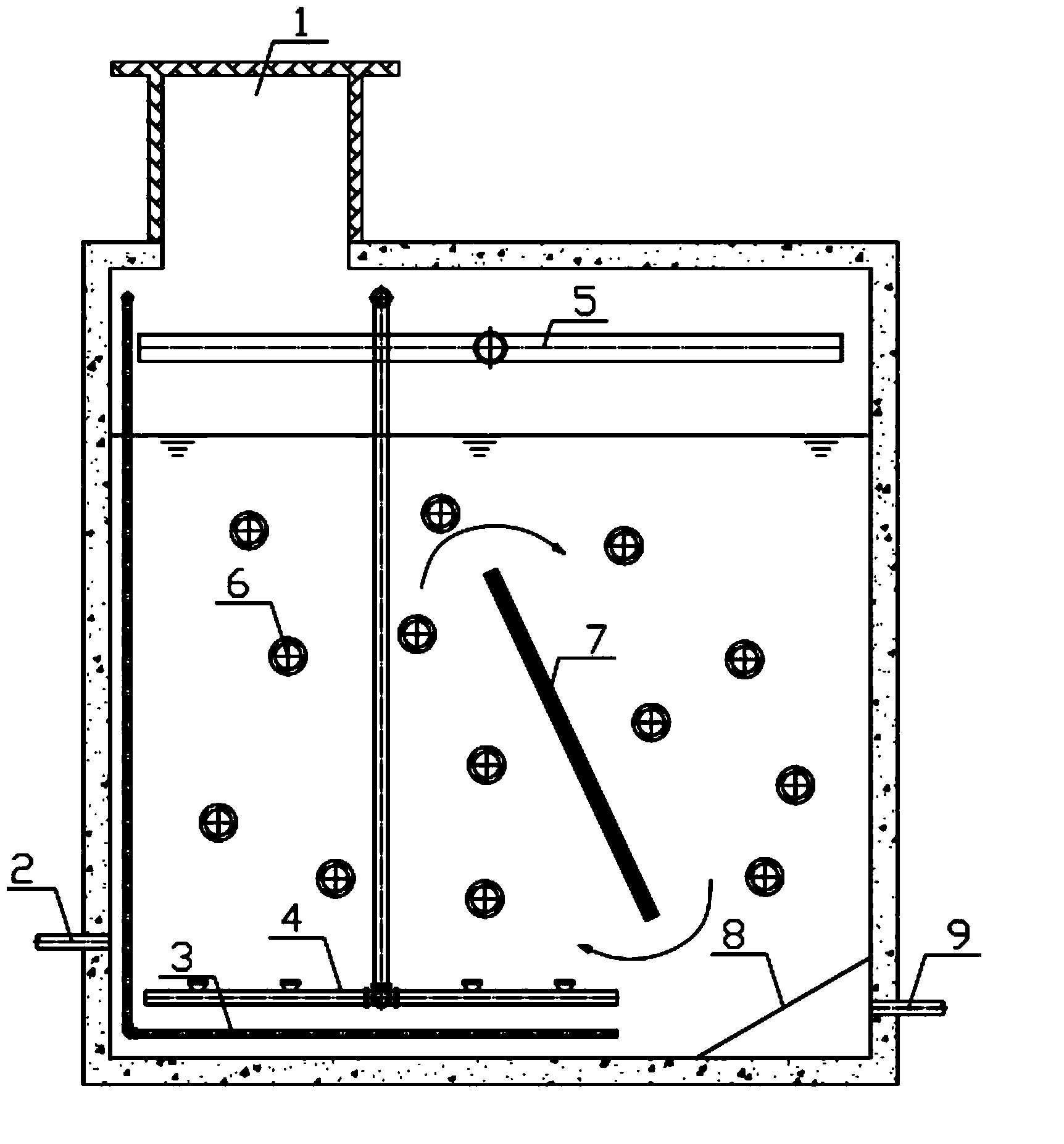

[0028] see figure 1 , a composite aerated moving bed biofilm reactor, comprising a reactor body 10 with a manhole 1 on one side of the top, a cover plate at the manhole 1 of the reactor body 10, and both sides of the side wall of the reactor body 10 The water inlet pipe 2 and the water outlet pipe 9 communicated with its inner cavity are arranged on the top, and the water inlet pipe 2 is set higher than the microporous aeration system 4 and the water outlet pipe 9, and the reactor main body 10 is provided with a circulation deflector 7, and the circulation A perforated tube aeration system 3 is provided on one side of the deflector 7 close to the inner bottom of the reactor main body 10, and a microporous aeration system 4 is provided above the perforated tube aeration system 3. The perforate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com