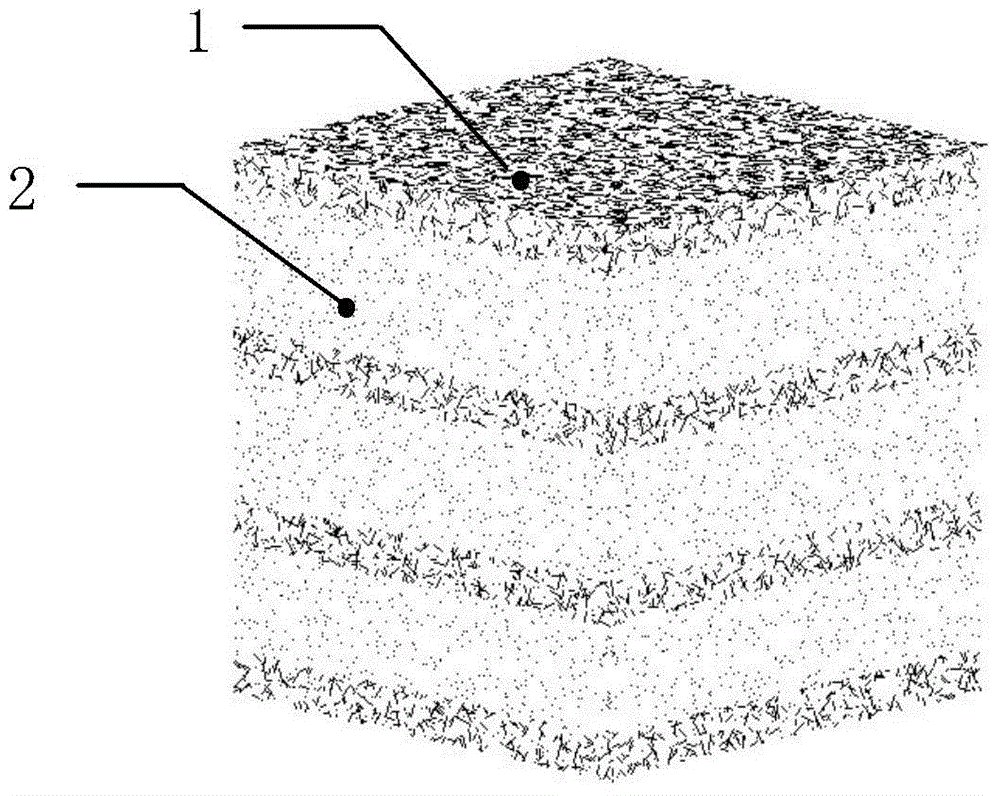

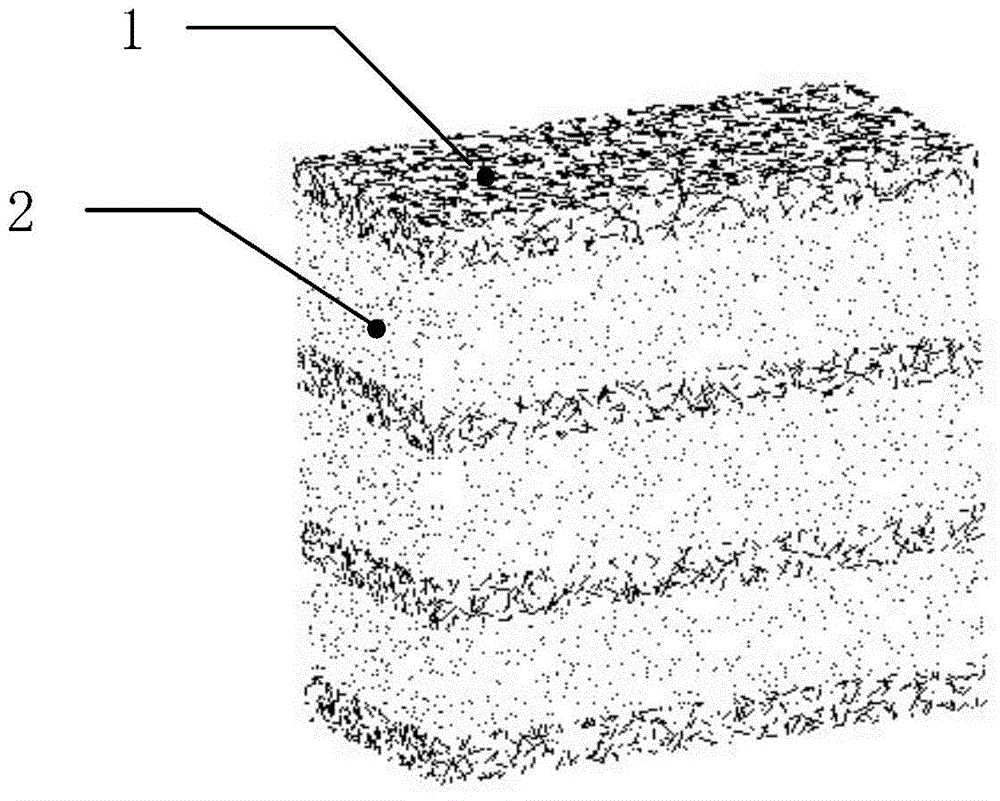

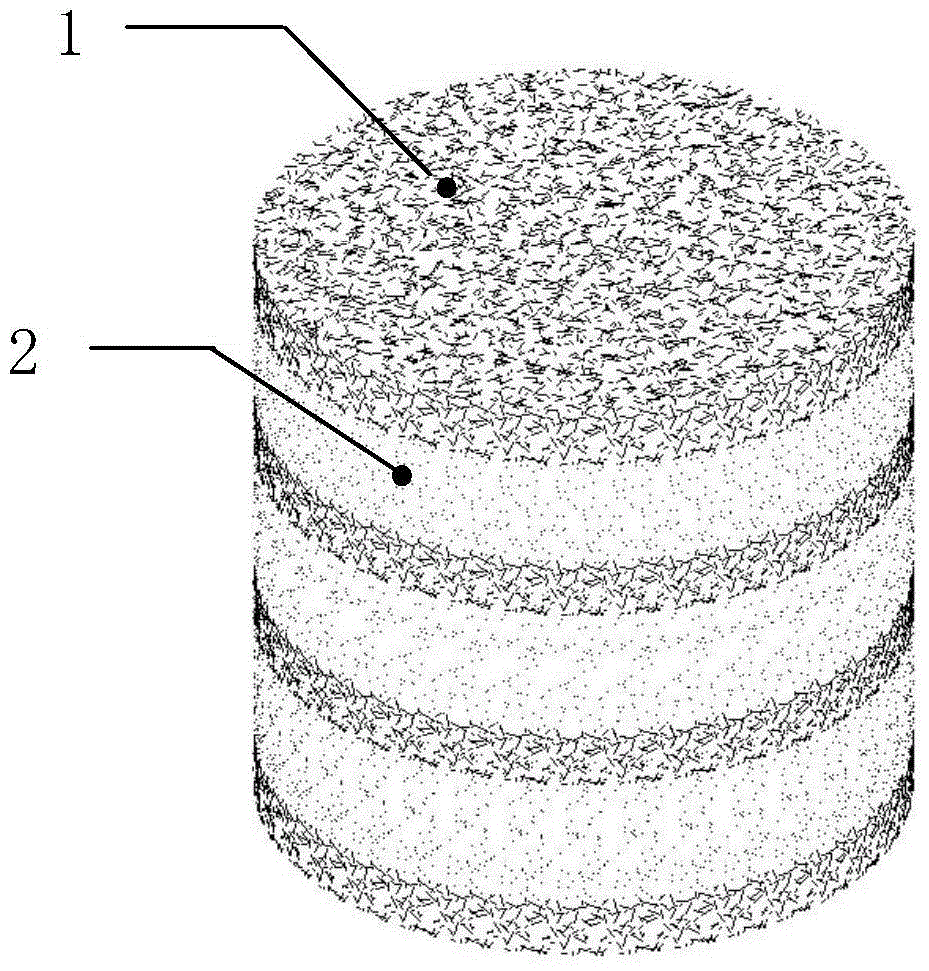

Preparation and application of sandwich-type multilayer immobilized bioactive filler

A biologically active, sandwich-type technology, applied in the field of water treatment, can solve the problems of weakened mechanical strength, easy falling off of embedded bodies, shortened service life of fillers, etc., to reduce the formation of dense films, high substrate mass transfer efficiency, and effective The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is now further described by taking nitrifying bacteria as an example. This embodiment is intended to further illustrate the immobilization, preparation and use of biologically active fillers for nitrifying bacteria, but the embodiments of the present invention are not limited thereto.

[0021] (1) Centrifuge and concentrate the domesticated nitrifying bacteria suspension to obtain a concentrated solution of nitrifying bacteria, take 45L of centrifuged and the bacteria content is 7.5x10 8 The concentrated solution of nitrifying bacteria per mL is ready for use;

[0022] (2) Take 30.0kg of polyvinyl alcohol in a water bath and heat it to 90°C and dissolve it in 200L of water to obtain a polyvinyl alcohol solution;

[0023] (3) Cool the polyvinyl alcohol solution in step (2) to 30°C and fully mix it with the bacterial concentrate obtained in step (1), add water to make the volume to 300L to obtain an embedding solution, and the polyvinyl alcohol in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com