Non-spark aluminum bronze powder for laser cladding, preparation method and cladding method

A technology of laser cladding and aluminum bronze, applied in coating, metal material coating process, etc., can solve problems such as gas explosion hazards, achieve the effects of preventing safety hazards, improving comprehensive performance, and preventing high-energy sparks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

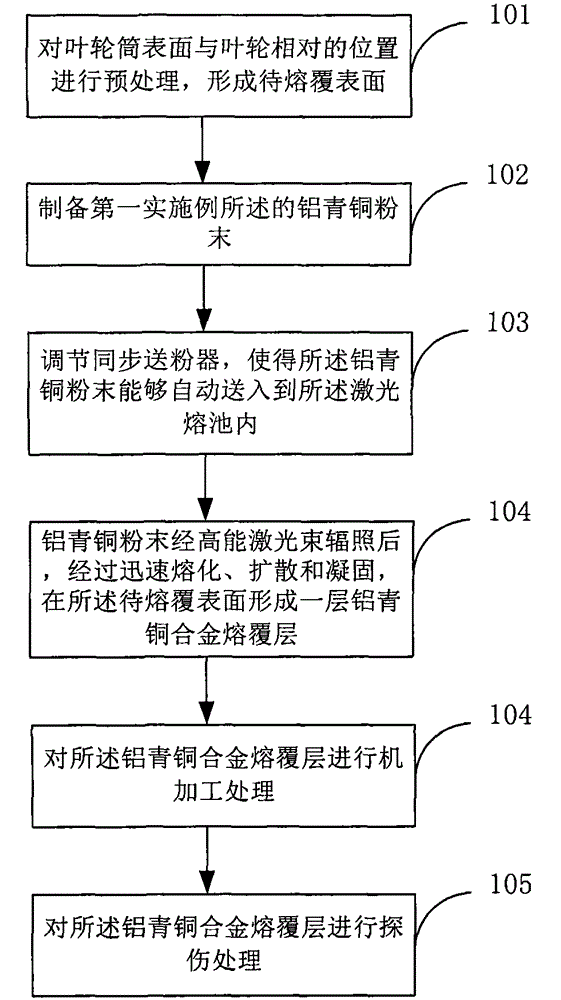

Method used

Image

Examples

Embodiment Construction

[0049] The first embodiment of the present invention provides a non-sparking aluminum bronze powder for laser cladding, the aluminum bronze powder comprising:

[0050] C<0.03%;

[0051] Si<0.05%;

[0052] Mn<0.10%;

[0053] S<0.006%;

[0054] Cr<0.5%;

[0055] Ni<0.5%;

[0056] Cu, 83% to 87%;

[0057] Al, 6%~10%;

[0058] and Fe<6.5%.

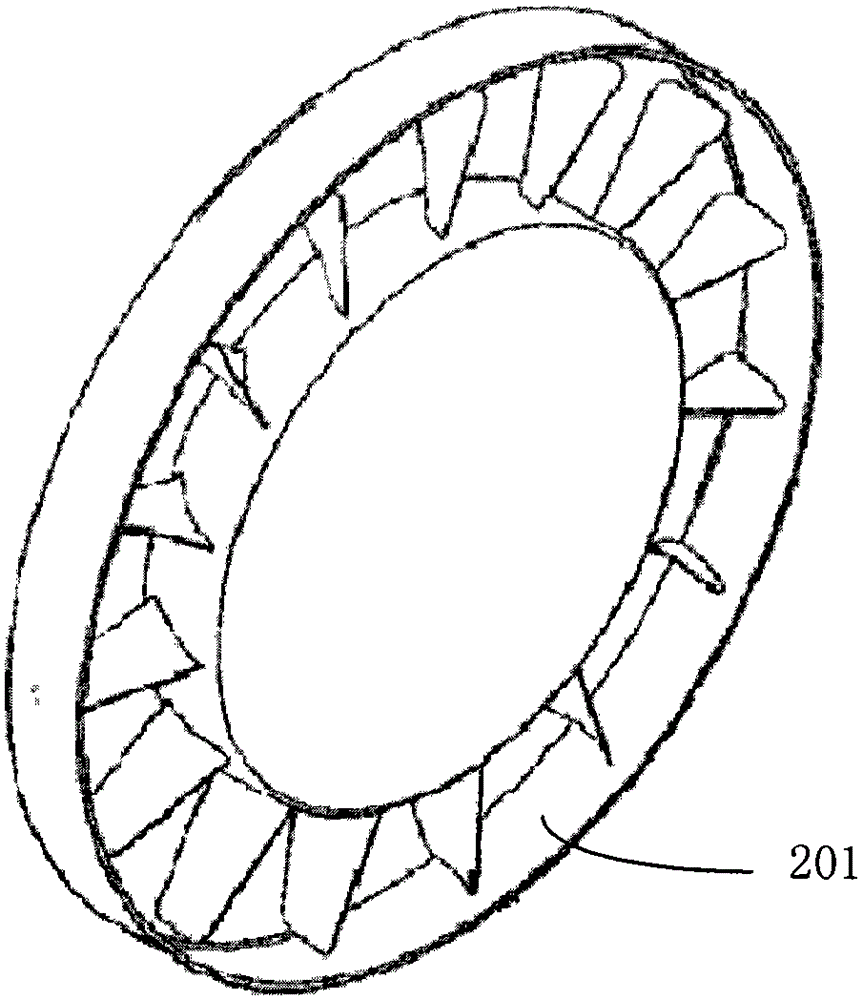

[0059]The aluminum bronze powder provided by the present invention is used for laser cladding. Aluminum bronze has better mechanical properties than brass and tin bronze, good fluidity in liquid state, small tendency of intragranular segregation and porosity, dense casting, corrosion resistance, Cold-resistant, wear-resistant, no sparks when impacted. Therefore, after the aluminum bronze powder of the present invention is used as the laser cladding on the surface of the impeller barrel of the coal mine ventilation fan, the alloy layer after cladding will not produce dangerous high-energy sparks, thereby solving the hidden danger of gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com